Chemical and mechanical polishing size and chemical and mechanical polishing method using said size

A slurry, water-based slurry technology, applied in chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve problems such as reduced margin, uneven wafer surface, and deterioration of semiconductor device characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

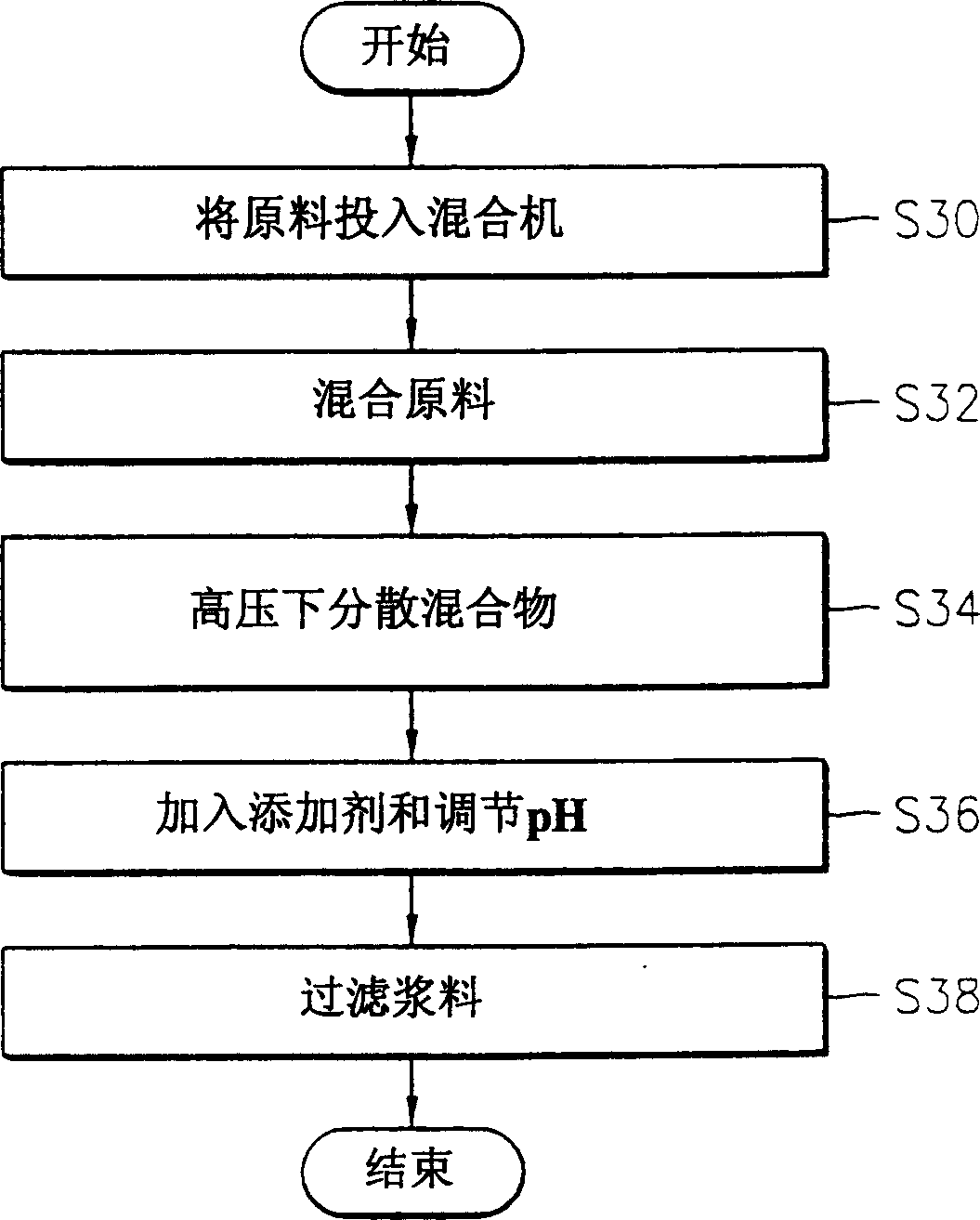

[0065] In this experiment, using image 3 According to the method, various slurries were prepared, these slurries contained 1% by weight of cerium oxide as the metal oxide abrasive particles, and polyammonium carboxylate (APC) as the anionic polymer deactivator, while varying the content of APC.

[0066] A cladding substrate (blanket substrate) of PE-TEOS with a thickness of 10000 Å and a silicon nitride layer (Si 3 N 4 ) coated substrate as a sample.

[0067] Referring to Table 1, the samples were subjected to the CMP process using slurries with different APC contents, and the removal rate and the selectivity ratio of oxides and nitrides were measured. At this time, using a Mirra apparatus (manufactured by AMAT) having an IC1000 upper pad and a Suba4 lower pad, CMP was performed under conditions of a down force of 4 psi and a table speed of 77 rpm.

[0068]

APC content (weight%)

Removal rate ( / min)

selection ratio

Oxide layer (PE-...

experiment example 2

[0071] In this experiment, using image 3 method, the slurry was prepared by varying the APC concentration (0 wt% and 0.8 wt%) while varying the amount of ceria metal oxide abrasive particles (1 wt% and 5 wt%). Preparation of oxide layer (PE-TEOS) clad substrate and silicon nitride layer (Si 3 N 4 ) clad substrate (the same substrate as used in Experimental Example 1) was used as a sample. The prepared slurry was used to perform CMP on the sample, and the results are shown in Table 2.

[0072]

[0073] As shown in Table 2, as the content of abrasive particles increases, the removal rate of oxide layer and silicon nitride layer increases. For the case where no APC is added, the selectivity ratio is low, below 5:1. When 0.8% by weight of APC was added to the slurry, the removal rate of the silicon nitride layer dropped abruptly, whereby the selectivity increased to over 50:1. On the contrary, when the content of abrasive particles increases, the removal rate of oxi...

experiment example 3

[0074] In this experiment, using image 3 method, various slurries containing 1% by weight of cerium oxide and 1% by weight of APC were prepared while adjusting the pH of the slurry by adding alkaline additives such as KOH, TMAH and choline. The prepared samples were the same as those in Experimental Example 1.

[0075] After performing CMP using the prepared slurry and samples, the selectivity ratio of oxides to nitrides was measured. At this time, using an apparatus (manufactured by Presi) having an IC1000 upper pad and a Suba4 lower pad, the CMP process was performed under the conditions of a down force of 5 psi and a stage speed of 65 rpm. The results are shown in Table 3.

[0076] Alkaline Additive

pH of slurry

selection ratio

none

7.2

1

KOH

7.5

1.08

TMAH

7.5

1.17

Choline

7.5

1.18

[0077] (Remarks: The selection ratio in Table 3 is the standard value wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com