Flat permanent magnetic DC vibrating motor

A vibrating motor, permanent magnet DC technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem of low utilization of winding space, achieve the effects of saving battery energy, facilitating mass production, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

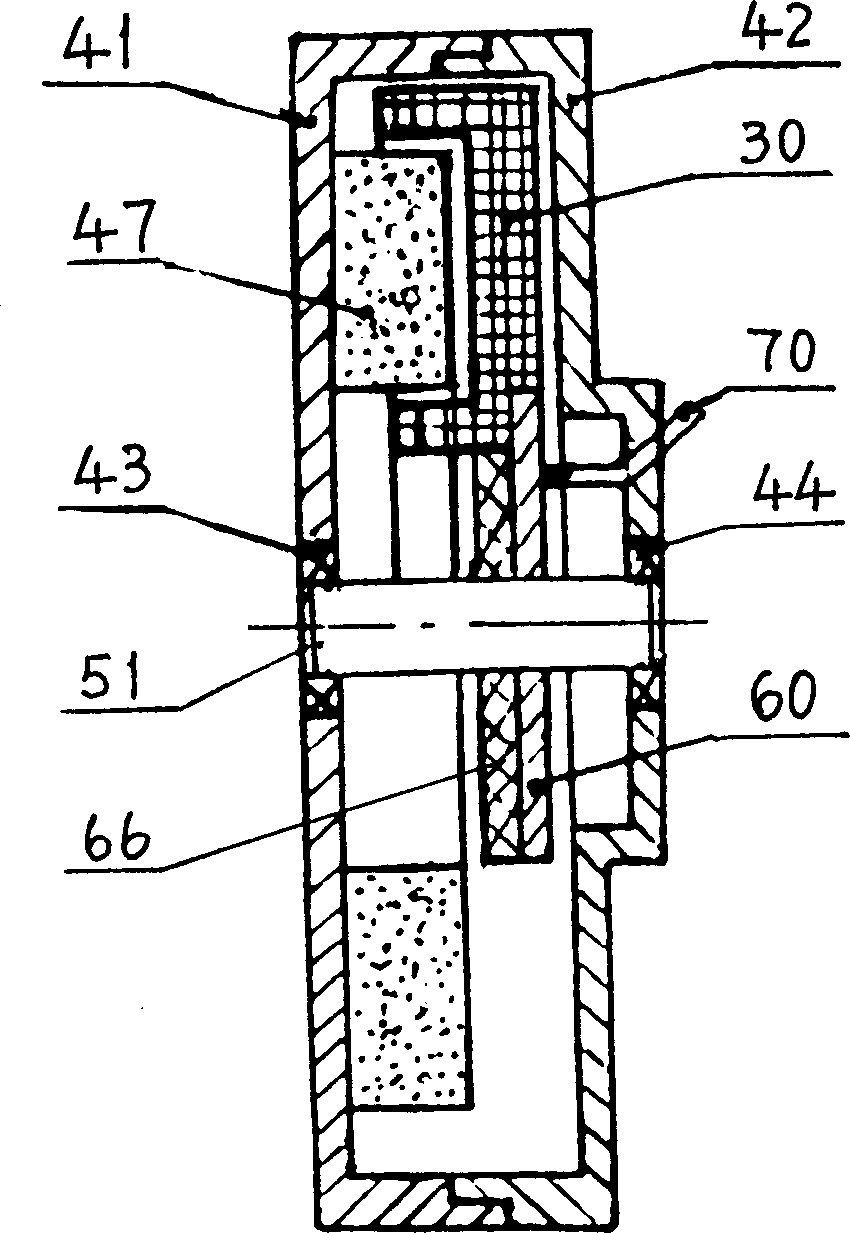

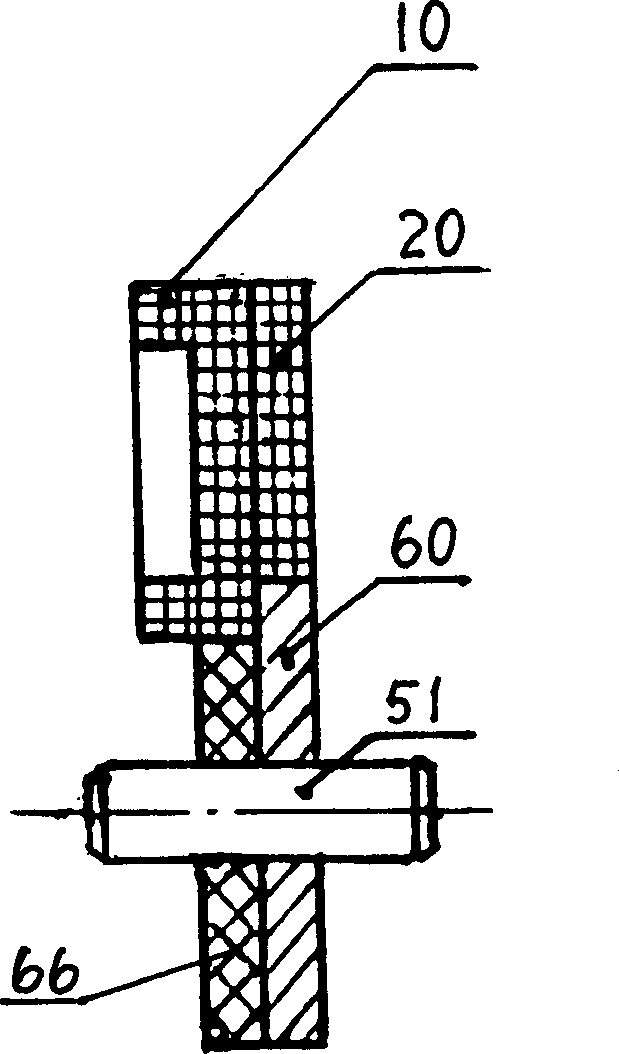

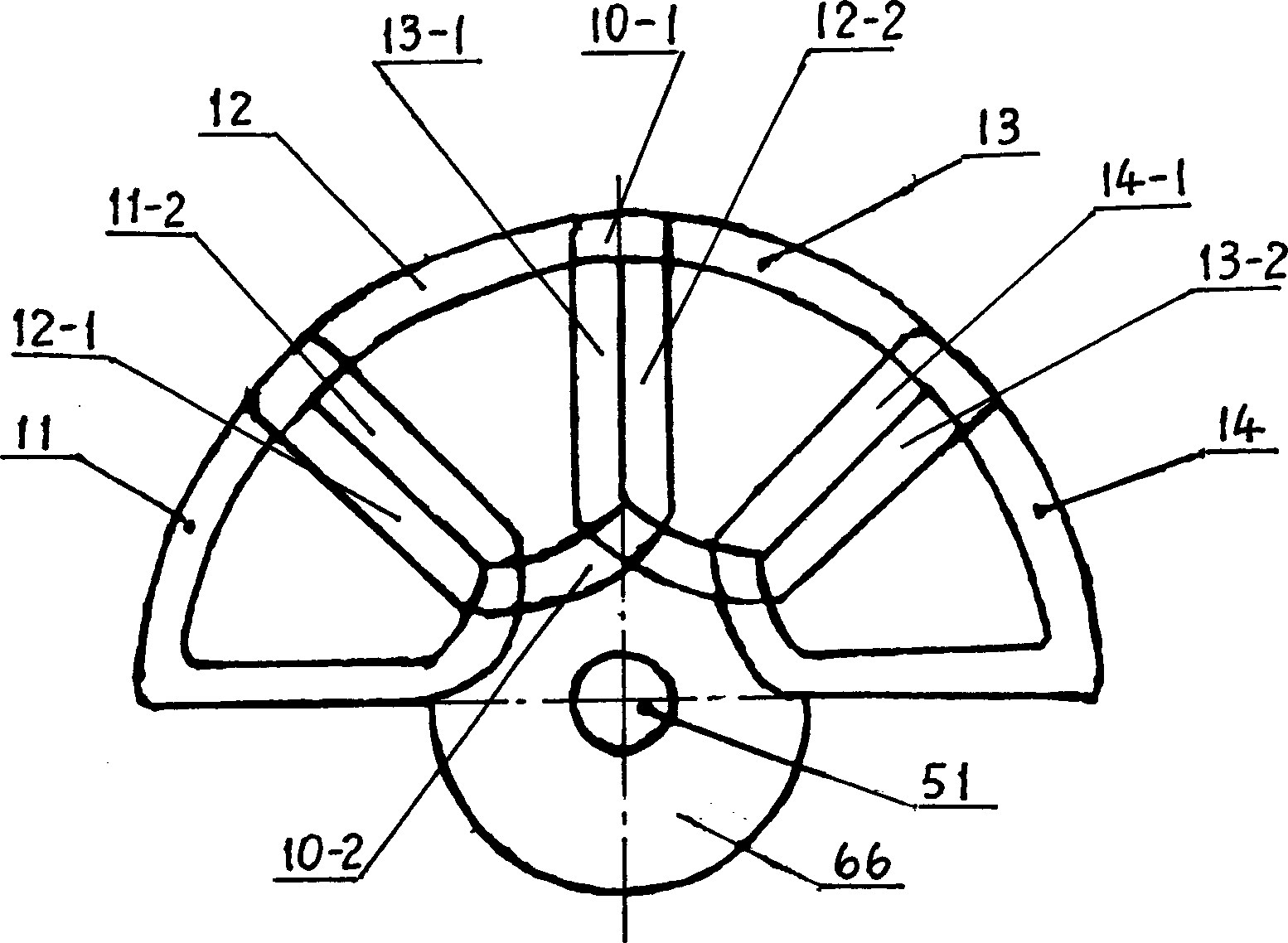

[0019] see first figure 1 . The flat permanent magnet DC vibration motor of the present invention includes a rotor 30 , a stator 40 , brushes and lead wires 70 . Wherein, the shell of the stator 40 is formed by fastening the left casing 41 and the right casing 42, figure 1 Shown in the left casing 41 left end inboard permanent magnet magnetic pole 47. In this embodiment, the number of pole pairs of the permanent magnetic poles 47 is 3, and the 6 magnetic poles are evenly distributed on the circular plane. One end of the permanent magnet pole 47 protrudes into the semicircular annular groove on the end surface of the rotor winding of the rotor 30 . The permanent magnet pole 47 is made of high-performance NdFeB permanent magnet material, and forms multiple pairs of poles through axial multi-pair magnetization. The left casing 41 and the right casing 42 of the stator are punched out with a high magnetic permeability thin plate. Two self-lubricating bearings 43 and 44 are riv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com