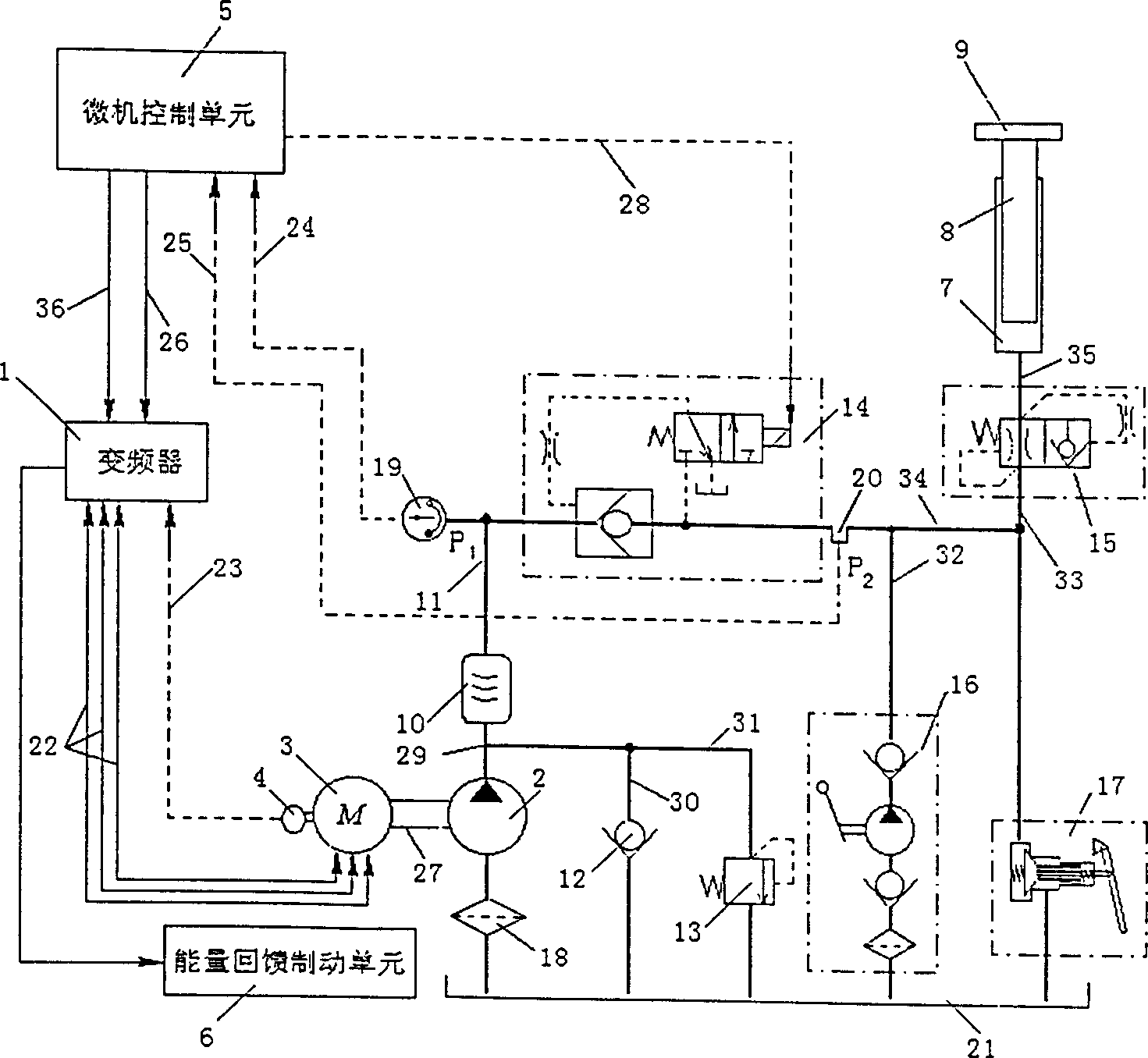

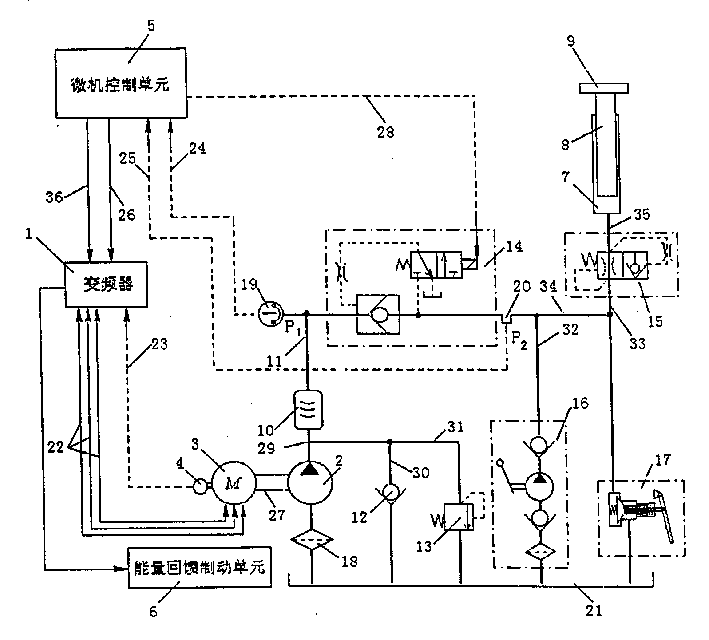

Frequency-varying driving elevator hydraulic control system

A hydraulic control system and variable frequency drive technology, applied in elevators, transportation and packaging, etc., can solve the problems of not fully utilizing the energy saving effect of the variable frequency speed regulation system, high energy consumption, and complex structure of the integrated control valve block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] see figure 1 As shown in the figure, the motor 3 is rigidly connected coaxially with the hydraulic pump / motor 2 through the coupling 27, and the pump / motor 2 is connected to the hydraulic control check valve 14 through the pipeline 29, the pressure pulsation suppressor 10, and the pipeline 11 , the hydraulic control check valve 14 is connected to the pipeline 33 through the pipeline 34 , the pipeline 33 is connected to the speed limiting shut-off valve 15 , and the speed limiting shut-off valve 15 is connected to the plunger cylinder 7 through the pipeline 35 . The circuit safety valve 13 is connected to the pipeline 29 through the pipeline 31 to ensure the safety of the oil outlet / inlet pressure of the pump / motor. The pressure sensor 20 is connected to the pipeline 34 to detect the pressure of the oil outlet of the pump / motor 2 . The hand pump 16 is connected to the hydraulic cylinder 7 through pipelines 34 , 33 , 35 .

[0059] The working principle of the car speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com