Delivery container

A technology for discharging containers and outlets, applied in packaging, single handheld devices, transportation and packaging, etc., can solve the problems of bacteria and external air entering at the same time, and complicate the composition, so as to prevent bacteria from invading from the outside and form a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

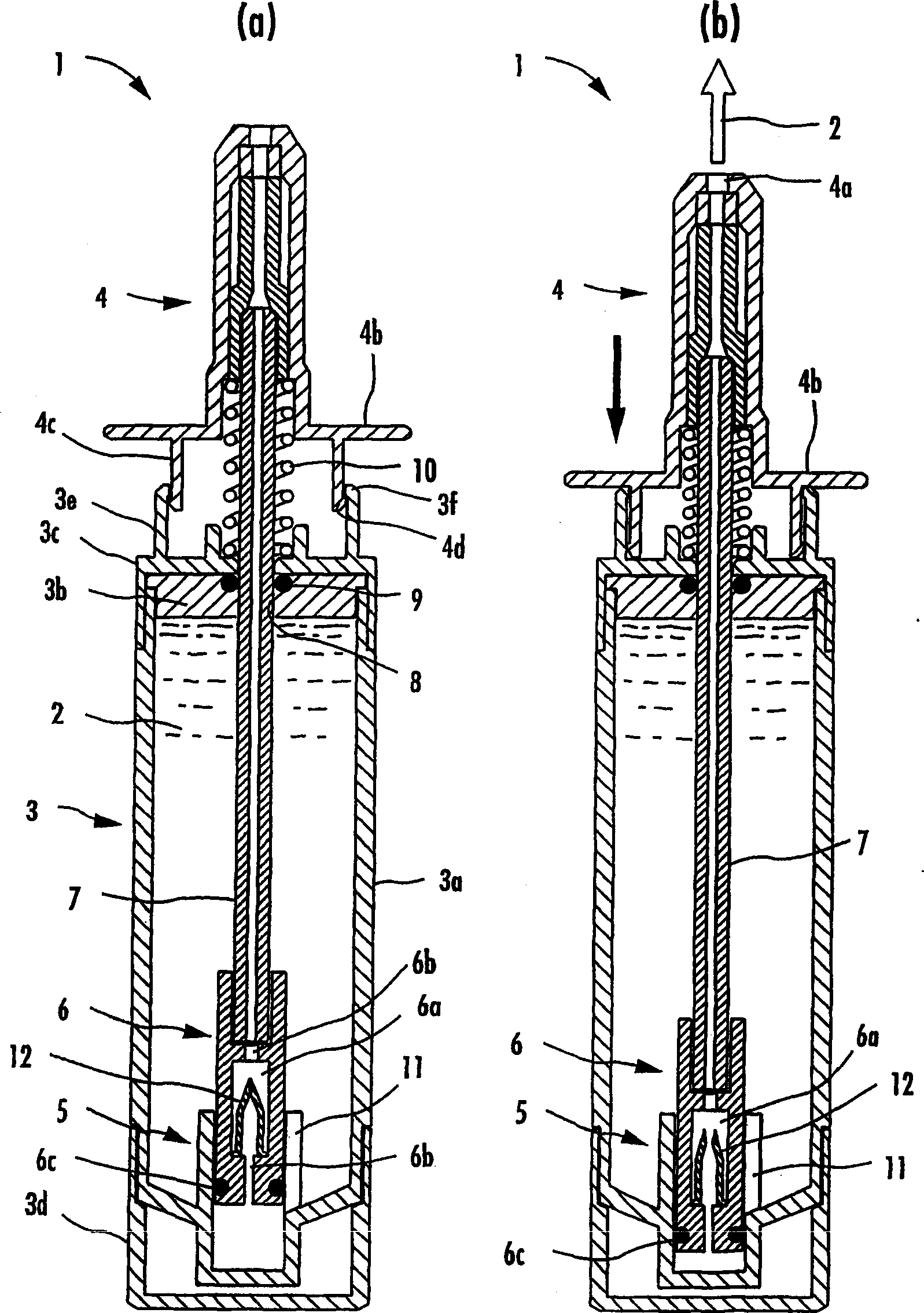

[0020] Refer below Figure 1 to Figure 3 , The specific embodiments of the present invention will be described.

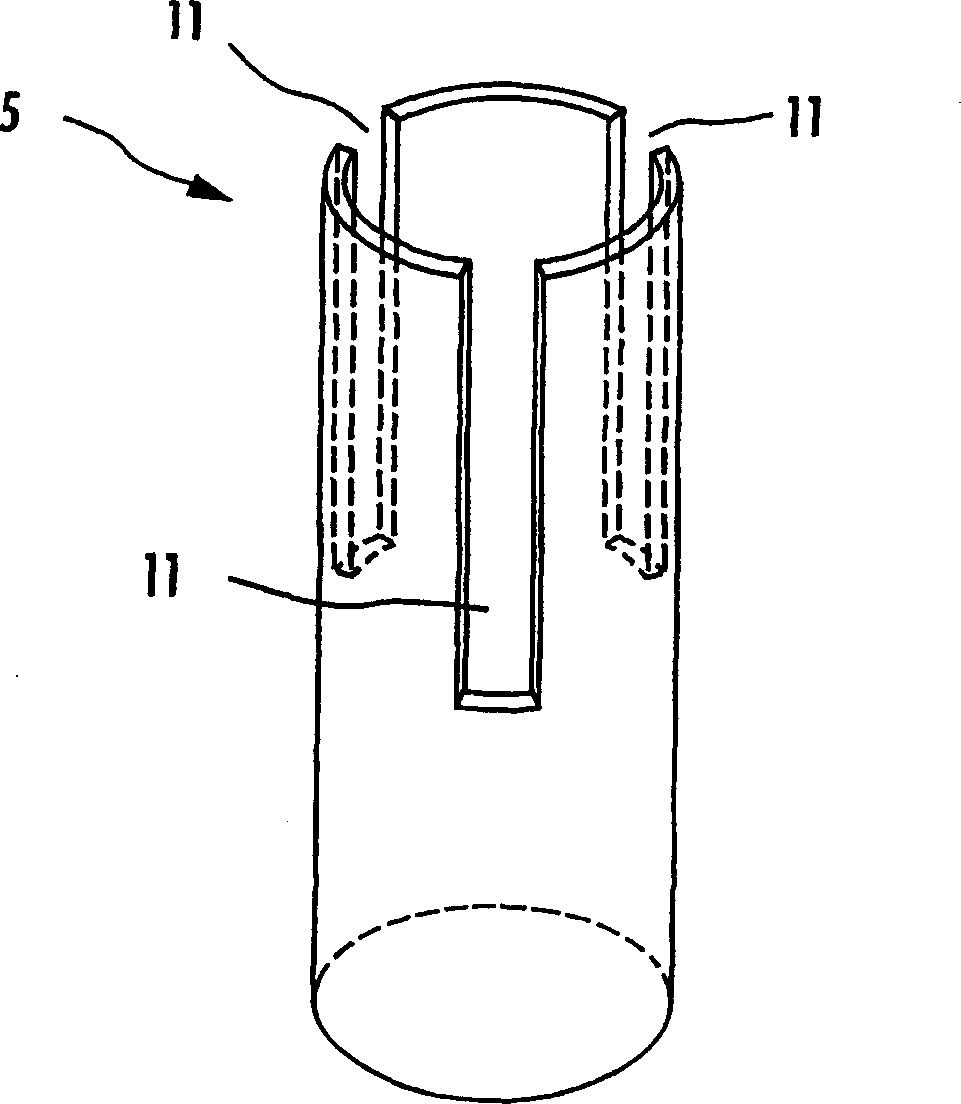

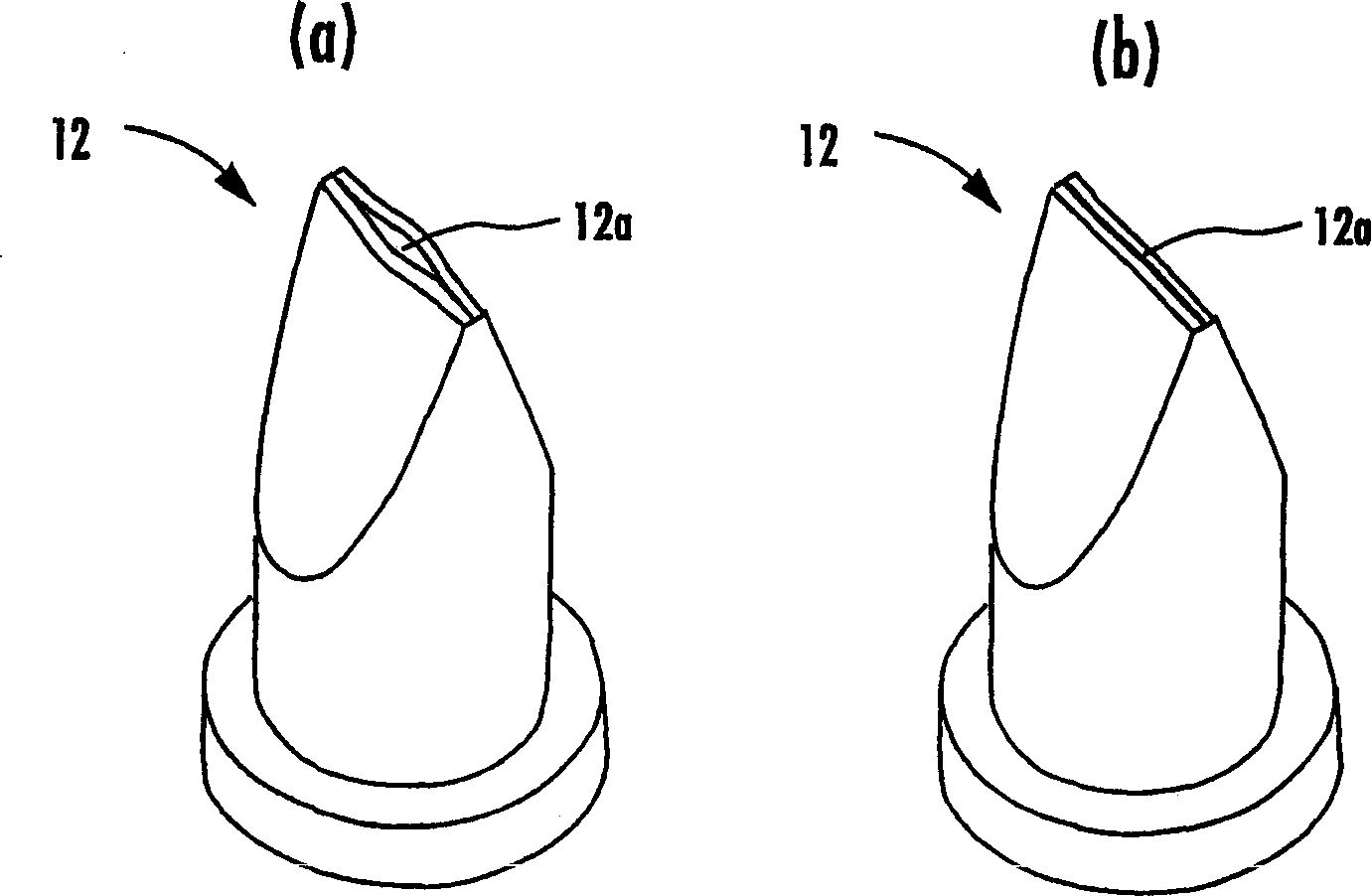

[0021] The discharge container 1 of this embodiment is as figure 1 (a) and figure 1 As shown in (b), there is a main body 3 containing the liquid medicine 2 and a top cap 4 provided above the main body 3. In addition, below the inside of the main body 3, a cylindrical cylinder 5 is integrated with the main body 3 in the vertical direction, and a slidable cylindrical piston 6 is provided inside the cylindrical cylinder 5. The piston 6 is connected to the top cap 4 via a hollow center shaft 7 penetrating the upper part of the main body 3, and the vertical movement of the top cap 4 is transmitted to the piston 6 through the center shaft. As a result, in the discharge container 1 of the present embodiment, the top cap 4, the center shaft 7, and the piston 6 are connected in a substantially linear unit. In addition, the center shaft 7 protrudes upward from the main body 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com