Lateral embedded type diaphragm filter plate constructed from controllable constant temperature plate core and assembling process

A membrane filter plate and constant temperature plate technology, which is applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problem of inability to filter and press at constant temperature, achieve high quality assembly, improve prestress strength and service life, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

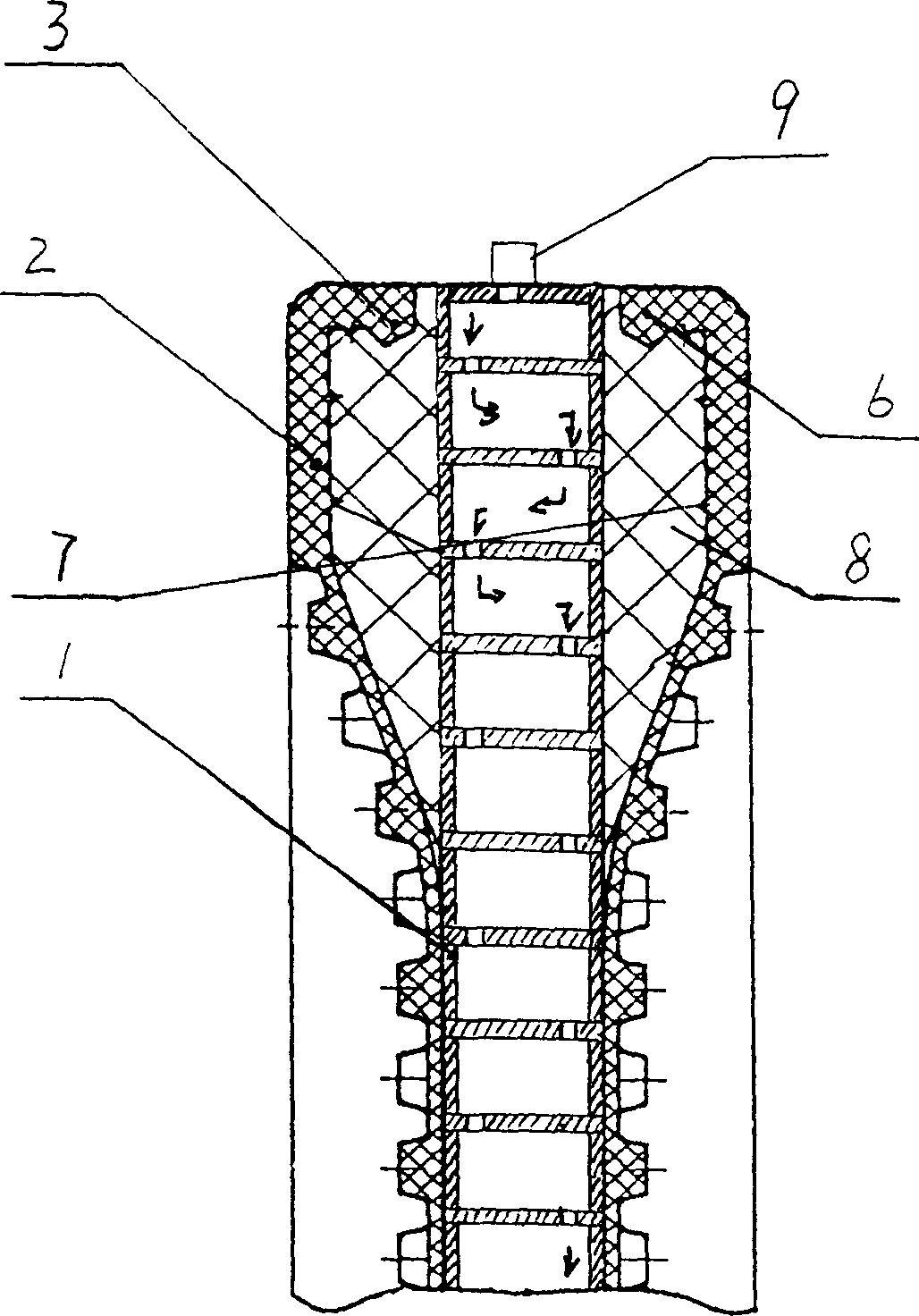

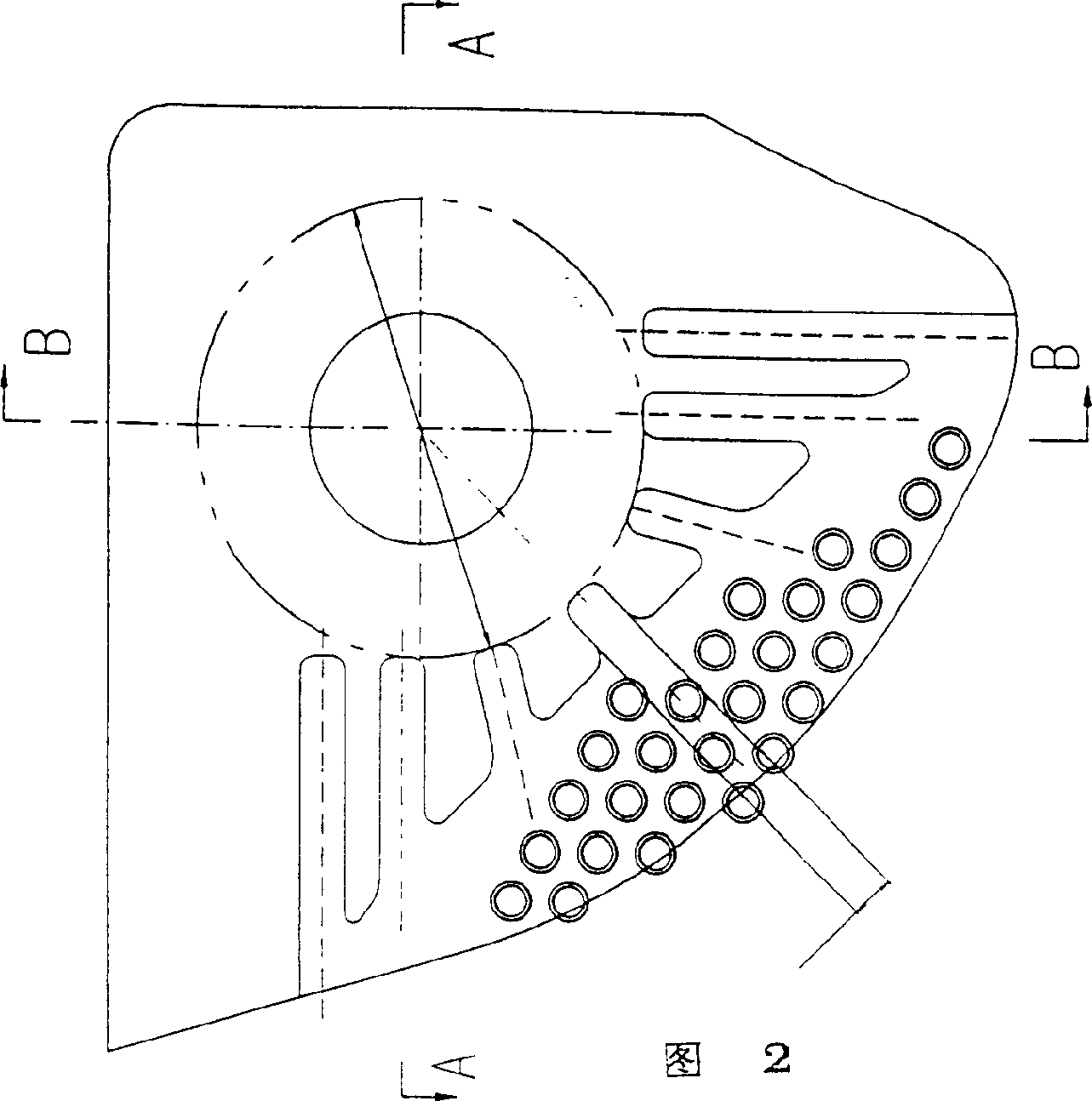

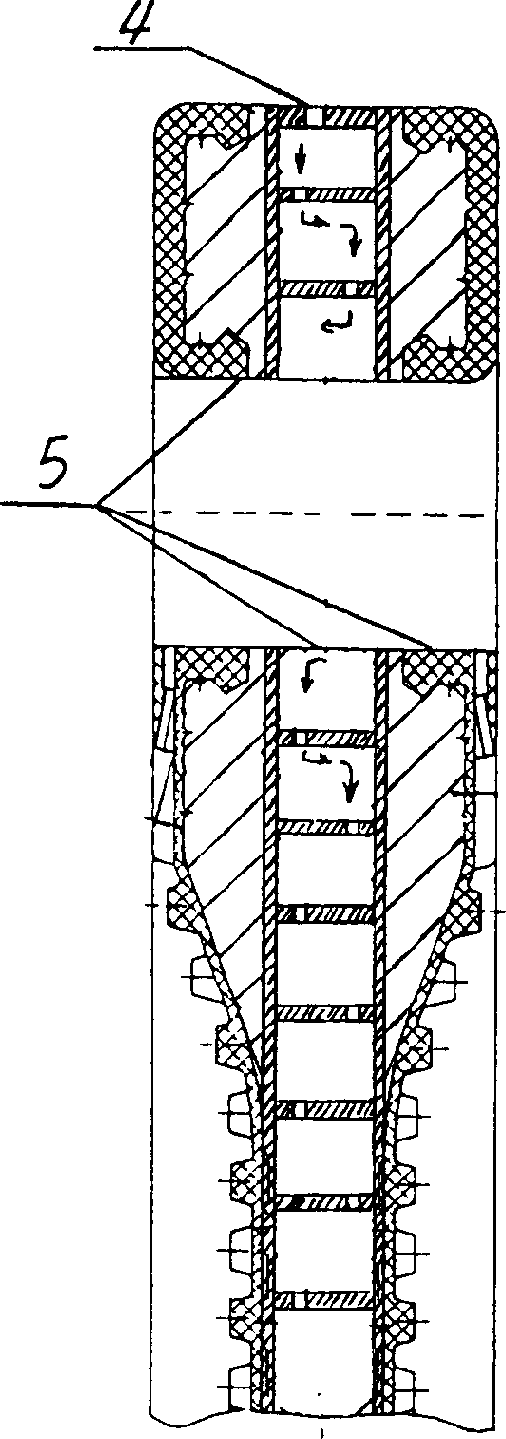

[0021] Embodiment 1: A side embedded diaphragm filter plate made of a constant temperature plate core, which includes a plate core 1 and a diaphragm 2, the plate core is a constant temperature plate core, and the fixed joint 3 of the diaphragm 2 is sealed with the side of the constant temperature plate core 1 Fixed combination, the thermostatic plate core is made of metal or non-metal materials, refer to Figure 1~6 . The fixed joint part 3 of the diaphragm 2 means that the flanged side in the diaphragm 2 is sealed and fixedly combined with the peripheral side of the thermostatic plate core 1 and the sides of each hole in the thermostatic plate core. The other side of the flanging in the diaphragm 2 becomes a part of the side of the thermostatic plate core. The support frame 8 in the thermostatic plate core 1 is metal or non-metal, and the fluid inlet and the fluid outlet 9 are arranged on the thermostatic plate core. The support frame 8 in the thermostatic plate core 1 is me...

Embodiment 2

[0022]Embodiment 2: On the basis of Embodiment 1, the fixed joint 3 of the diaphragm 2 refers to the flanged side of the diaphragm 2 and the side surface around the thermostatic plate core 1 in an interference-seal combination, and each hole in the diaphragm 2 is connected to the The surface of each hole in the thermostatic plate core 1 is in the form of an embedded sealing combination or a clamping and sealing combination.

Embodiment 3

[0023] Embodiment 3: On the basis of Embodiment 1, the sealing joint surface of the diaphragm 2 has more than one circle (1 circle or 2 circles or 3 circles...) annular sealing line 7, which forms a thermostatic plate core with damping isolation and sealing with the annular sealing line face is flat or side, see appendix figure 1 And attached Image 6 . The function of the annular sealing line 7 is to damp and block the penetration of fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com