Supporting structure

A technology of supporting structure and supporting wall, applied in transportation and packaging, escalators, etc., can solve the problems of high cost, poor material utilization, poor weight of molded components, etc., and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

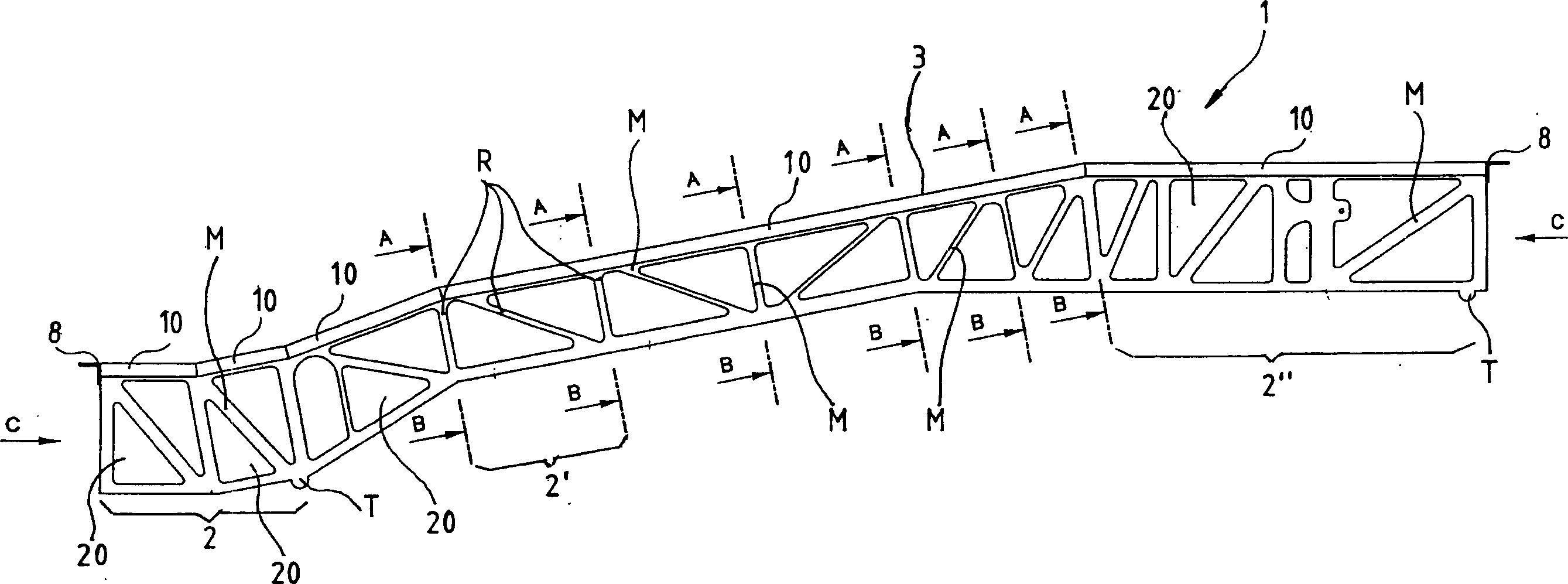

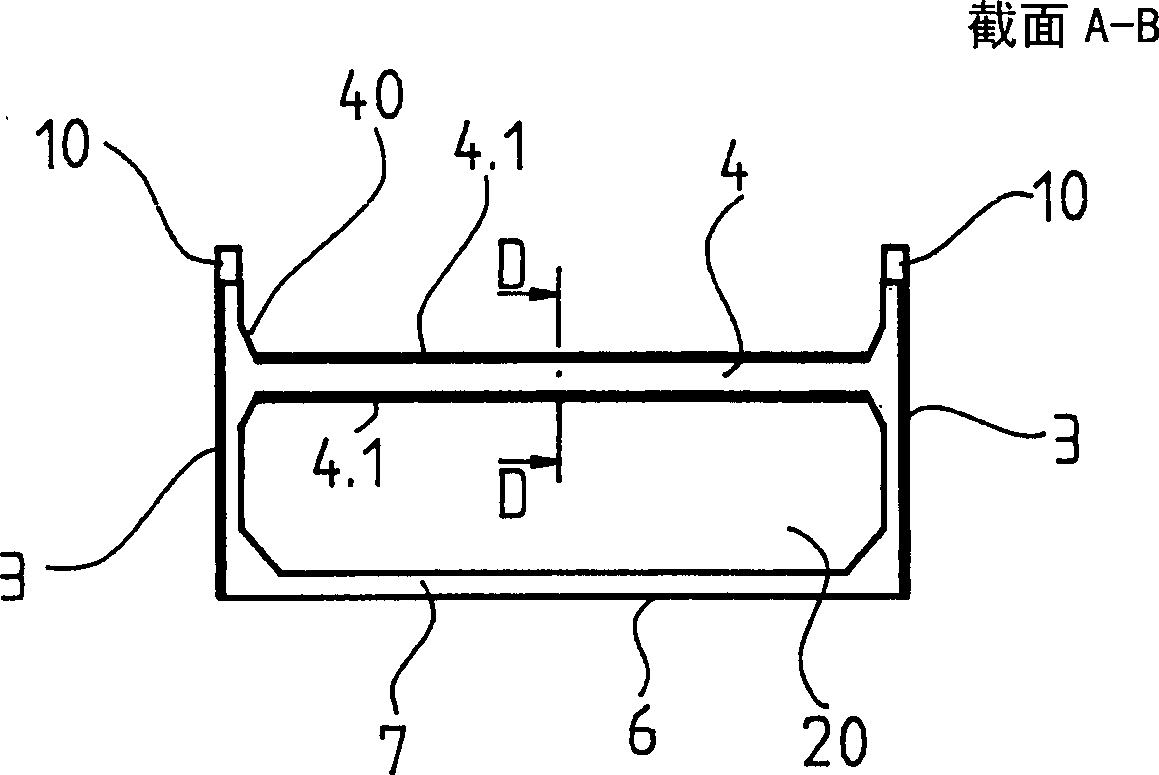

[0024] figure 1 A side view of the support structure 1 is shown in an installed position, eg of an escalator (not shown in detail) or of a moving walkway (not shown in detail). In this example the support wall 3 of the support structure 1 is shown, and the support wall 3 comprises several framing elements 2, 2', 2". Obviously, the support wall 3 may only comprise a single framing element 2, 2', 2 "." A frame element 2, 2', 2" is understood as a frame structure with at least one closed cutout. The support structure 1 of an escalator or moving walkway usually has two support walls 3, which are arranged at the bottom of the step conveyor belt of the escalator Both sides or both sides of the flat belt of the moving channel. The framing elements 2, 2', 2" of the support wall 3 are integral structures, that is, the framing elements 2, 2', 2" are made of one piece and do not have to be connected Various pieces together. The framing elements 2, 2', 2" may be made from flat (fiat), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com