Filled mining method

A technology of ore retention method and mining method, which is applied in the field of filling and retention mining method, can solve problems such as difficult to meet production capacity, and achieve the effects of improving mining efficiency and mining intensity, short filling length and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

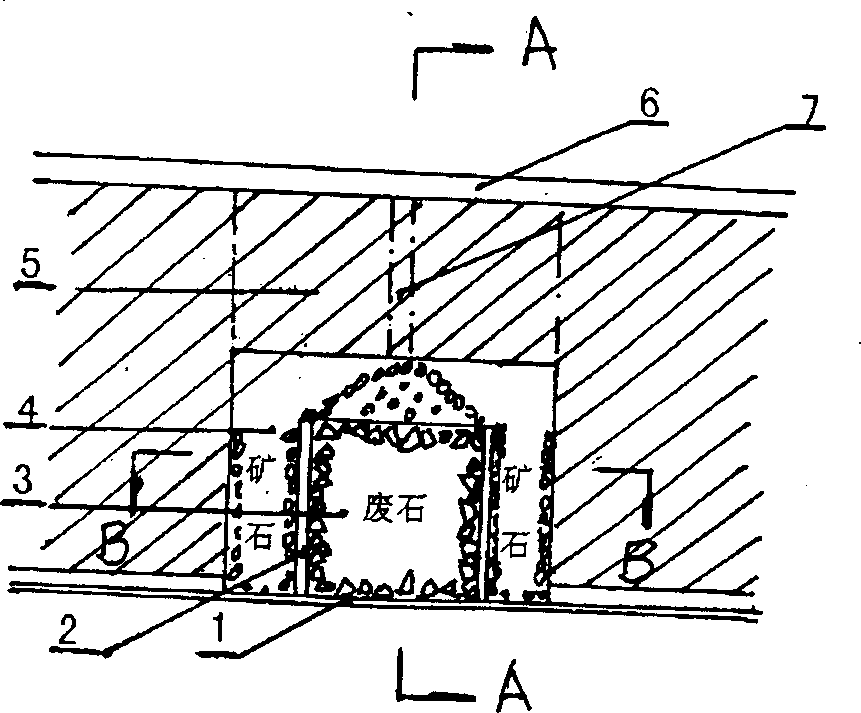

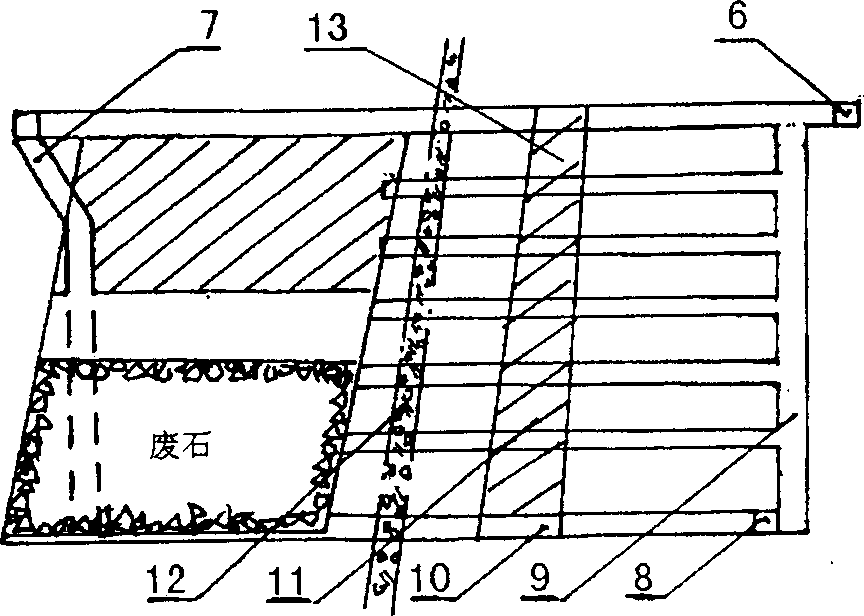

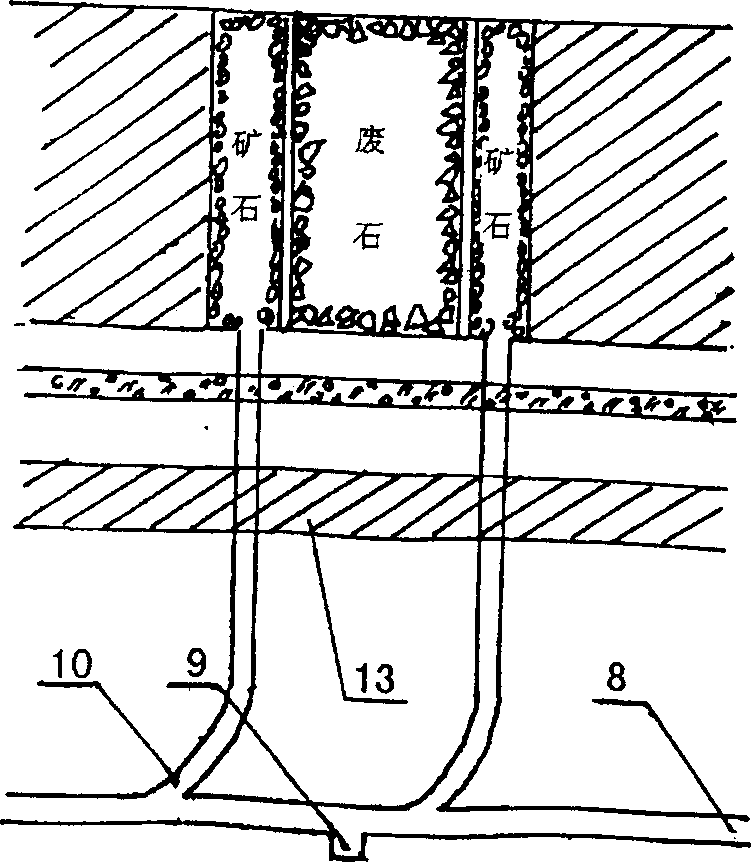

[0011] The ore body of line 42-48 in the middle section of -40 in the Gaocun mining area of Gaoyao Hetai Gold Mine in Gaoyao, Guangdong Province is 120m long, with an average thickness of 6.7m and an average grade of 9.8g / t. The trend of the ore body is consistent with the structural fracture zone, which is unstable and will cause a large number of caving after being exposed. The above method is used for this section of the ore body, and a section (average thickness 8-12m) is delineated, and artificial inter-columns are built from the middle to support the footwall. The adjacent stope is also mined by the shallow eye retention method. The center of the stope is excavated to fill the ventilation shaft 7, and the lower side of the vein is leveled 8, the mining quasi-raft 9 is excavated, and the stope joint road 11, and the rock loader Go out of the mine roadway 10, then cut and construct the reinforced concrete bottom column 1 to its bottom, start to construct two reinforced co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com