Baseplate for arm and suspension assembly

A suspension, substrate technology, applied in the installation of arm parts, alignment of tracks on magnetic disks, configuration/installation of recording heads, etc. Some stout and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the figures, the same reference numbers refer to the same elements. It should be understood that the dimensions of the various features in the drawings may not be to scale, or may not be to exact scale, but are shown for clarity and explanatory purposes.

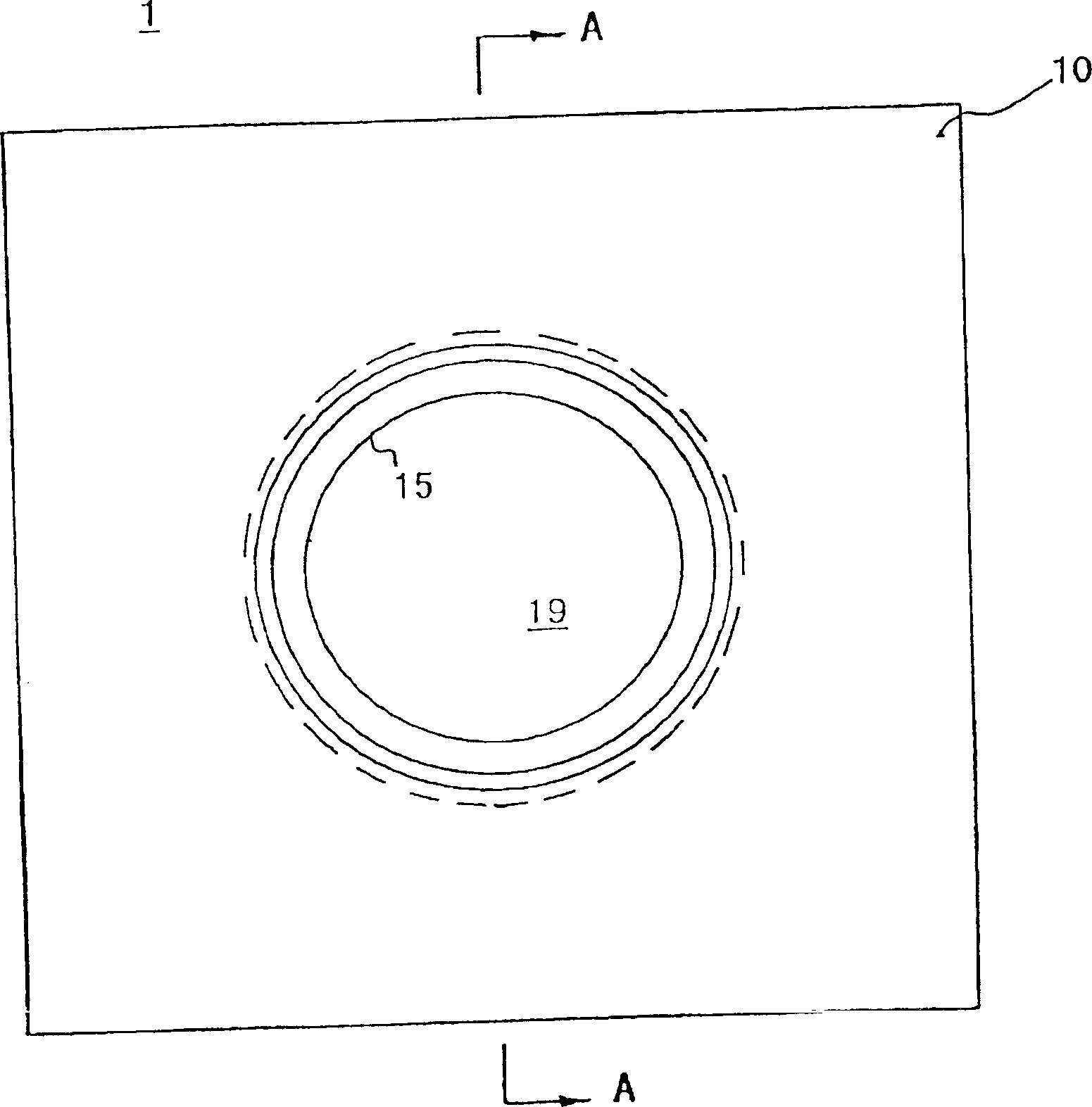

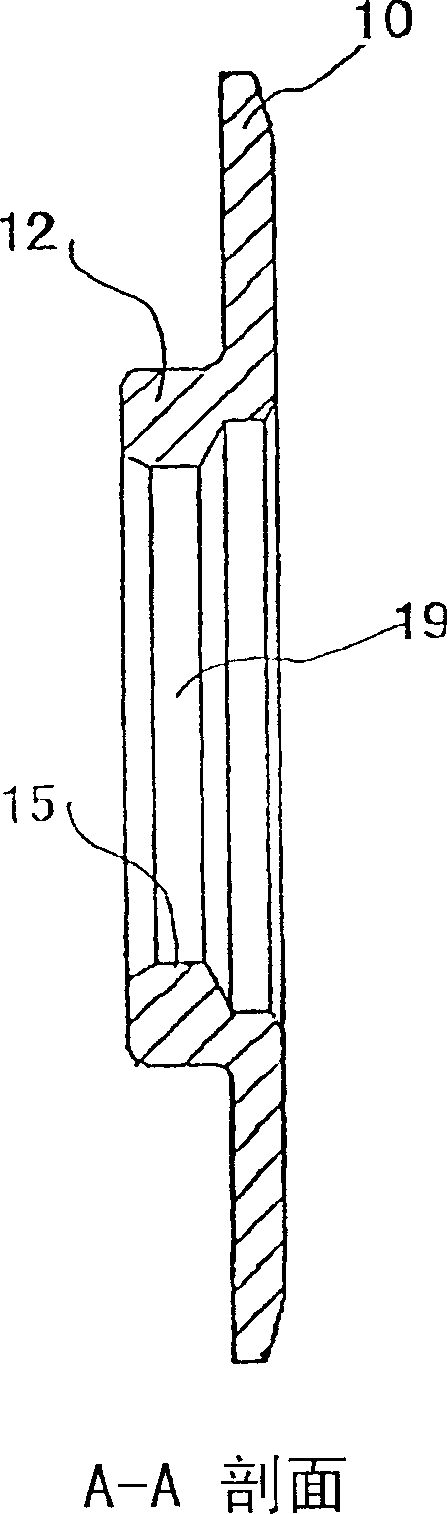

[0031] See Figure 1 and figure 2 . An actuator arm, which is an element of a head stack assembly (HSA), and a sensor suspension assembly are connected end-to-end through a substrate, which is part of the sensor suspension assembly. The base plate, generally designated 1 , includes a flat edge portion 10 and a cylindrical hub portion or boss 12 . The base plate is generally in the shape of an inner cylinder with a counterbore 11 , a fillet chamfer 13 and an inner diameter portion 15 . The counterbore 11 and inner diameter portion 15 are perpendicular to the plane of the substrate edge 10 . The hub 12 is inserted into the load beam boss clearance hole of the load beam 14, and the edge portion 10 is welded to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com