Purification and filtering plate for waste air from chemical Lab., and its mfg. method

A chemical laboratory and exhaust gas purification technology, which is applied in the field of exhaust gas purification treatment, chemical laboratory exhaust gas purification adsorption plate and its preparation, can solve the problems of secondary pollution, low degradation efficiency, easy loss of photocatalyst, etc., and achieve operating costs Low, strong adsorption capacity, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

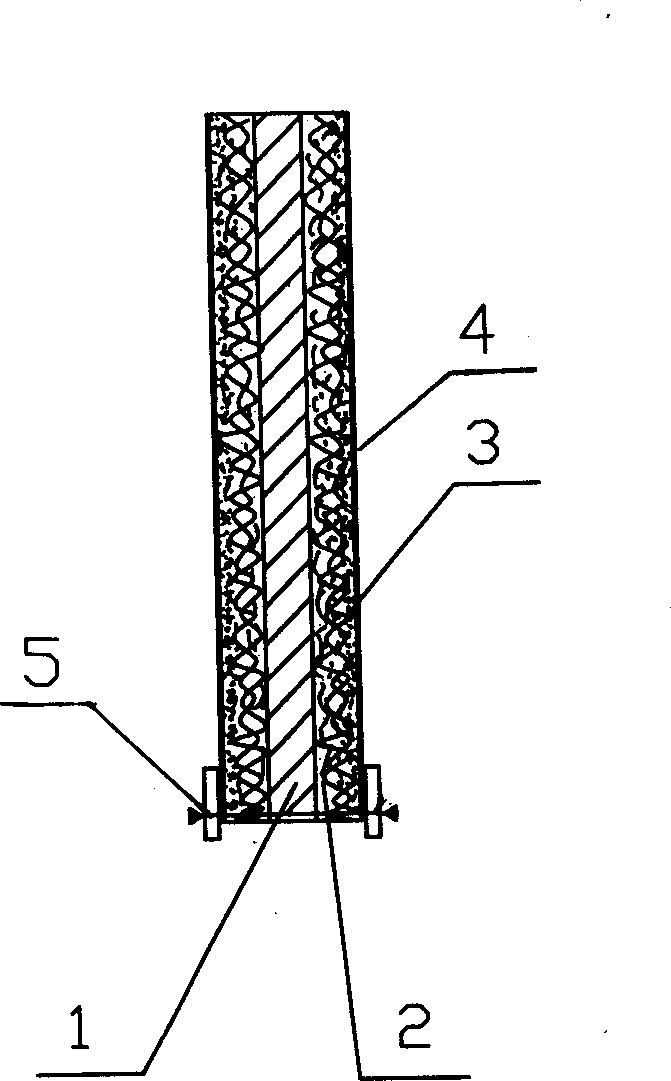

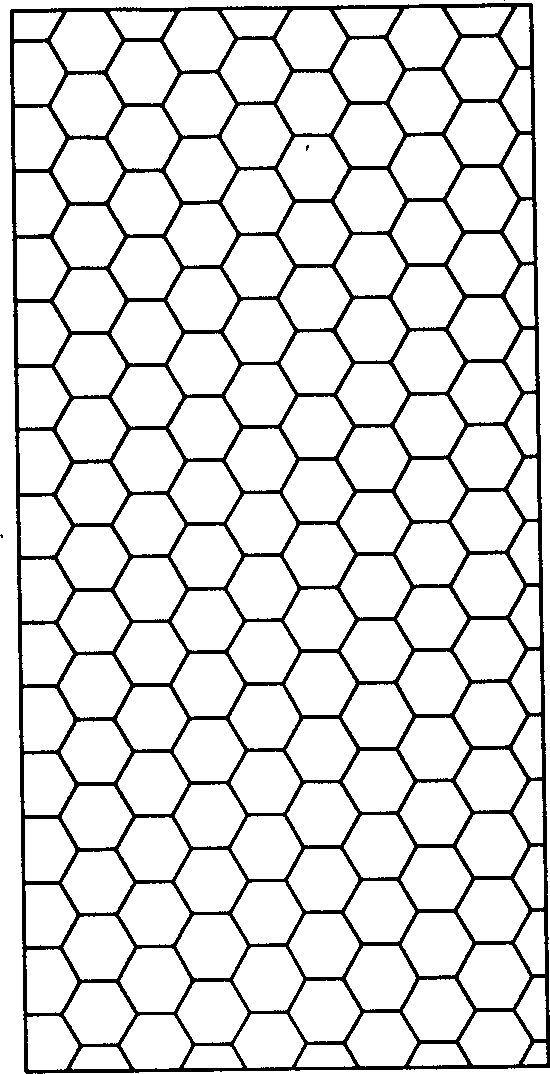

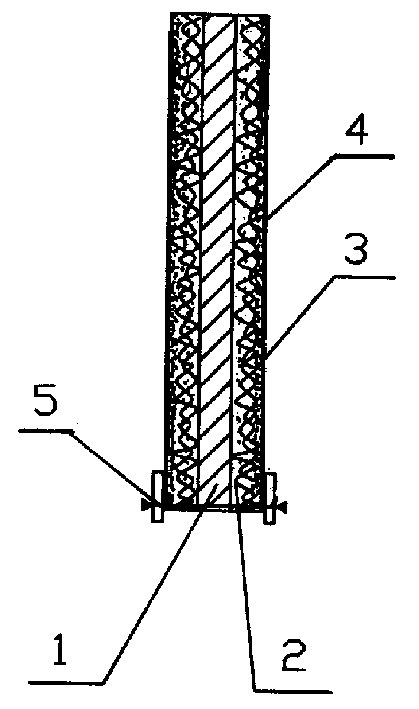

[0027] Example 1, the specific method is to mix 10-35nm TiO 2 , or Si-modified TiO 2 The semiconductor photocatalyst was dispersed in water with a solid content of 10%, and fully dispersed under the action of ultrasonic waves to obtain a stable slurry 1. Dissolve 1% carboxymethyl cellulose in slurry 1, and make it uniform under the action of ultrasonic waves to form slurry 2. Use a spray gun to press the slurry 1 to 150ml / m 2 Metered and evenly sprayed on the surface of the activated carbon fiber felt with a thickness of 3mm, and at a rate of 60ml / m 2 Measured, then sprayed slurry 2, put it into a blast drying oven at 180° C. for 2 hours, and then cut it according to the actual size for use. Using the above-mentioned supported TiO 2 Activated carbon fiber felt made of 300×400(mm) 2 The adsorption plate of the 3 In the simulated ventilation pipe, a UV lamp with a power of 15W and a wavelength of 253.7nm and an axial flow fan were installed, and it was placed in a 187-lite...

Embodiment 2

[0030] In Example 2, a purification adsorption plate was prepared according to the method of Example 1. The difference is: TiO 2 The particle size of the photocatalyst is 10 to 50 nm. Detected according to the method of implementation 1, the initial concentration of toluene was 1000ppm, and the CO2 in 3 hours 2 The generation amount was 1000 ppm.

Embodiment 3

[0031] In Example 3, the purification adsorption plate was prepared according to the method of Example 1. The difference is: in the process of spraying the photocatalyst slurry to the activated carbon fiber, only the above-mentioned slurry 2 is sprayed, and the pressure is 210ml / m2. 2 Metered without spraying Slurry 1. Detected by the method of Example 1, the initial concentration of toluene was 1000 ppm, and the concentration of toluene was 150 ppm after 5 minutes; the purification rate was 85% after 5 minutes; after 3 hours, CO 2 The generation amount was 700 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com