Method for producing stable chlorine dioxide with high purity by using gas stripping technique

A chlorine dioxide, production method technology, applied in the direction of chlorine oxide, chemical instruments and methods, separation methods, etc., can solve problems such as excessive methanol content, unstable product quality, and field limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

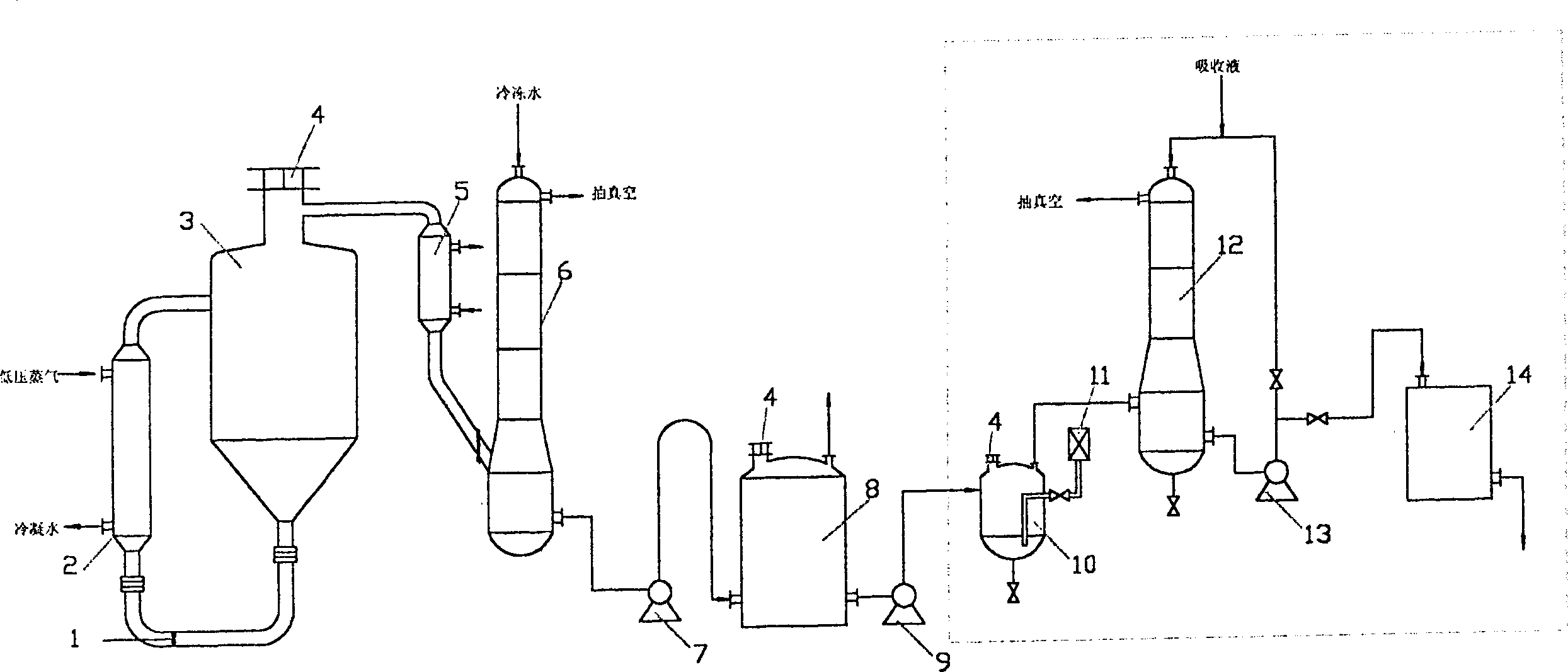

Method used

Image

Examples

Embodiment

[0012] Add 50M to a dissolution tank with a stirrer 3 Clear water, start the agitator, and 1250Kg of Na 2 CO 3 and 1190Kg of NaOH are poured into the dissolving tank, and after all of them are dissolved, slowly add 1250Kg of H 2 o 2 (100%), continue to stir for 30 minutes after adding, and the absorption solution prepared in this way can be used after standing for 24 hours.

[0013] Taking the preparation of chlorine dioxide by the R8 method as an example, 164 kg of sodium chlorate, 100 kg of sulfuric acid and 15 kg of methanol react in the generator to produce 100 kg of chlorine dioxide gas, and the concentration obtained with 7°C frozen water is Liter 10 grams of chlorine dioxide aqueous solution 10t. The aqueous solution is transferred to a desorption tank for desorption and air stripping, and then the prepared absorption liquid is used to react with the chlorine dioxide gas stripped out to obtain 50t of stable chlorine dioxide with a content of about 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com