Stainless steel door and window section material with plastic lining frame and its manufacturing method

A plastic door and window, stainless steel technology, applied in the direction of the wing leaf frame, etc., can solve the problems of thermal insulation, energy saving and sound insulation performance are not ideal, low-end buildings are not suitable for use, stainless steel doors and windows are expensive, etc., to achieve excellent thermal insulation, energy saving and insulation Acoustic performance, excellent service life, and the effect of isolating sunlight and atmospheric corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

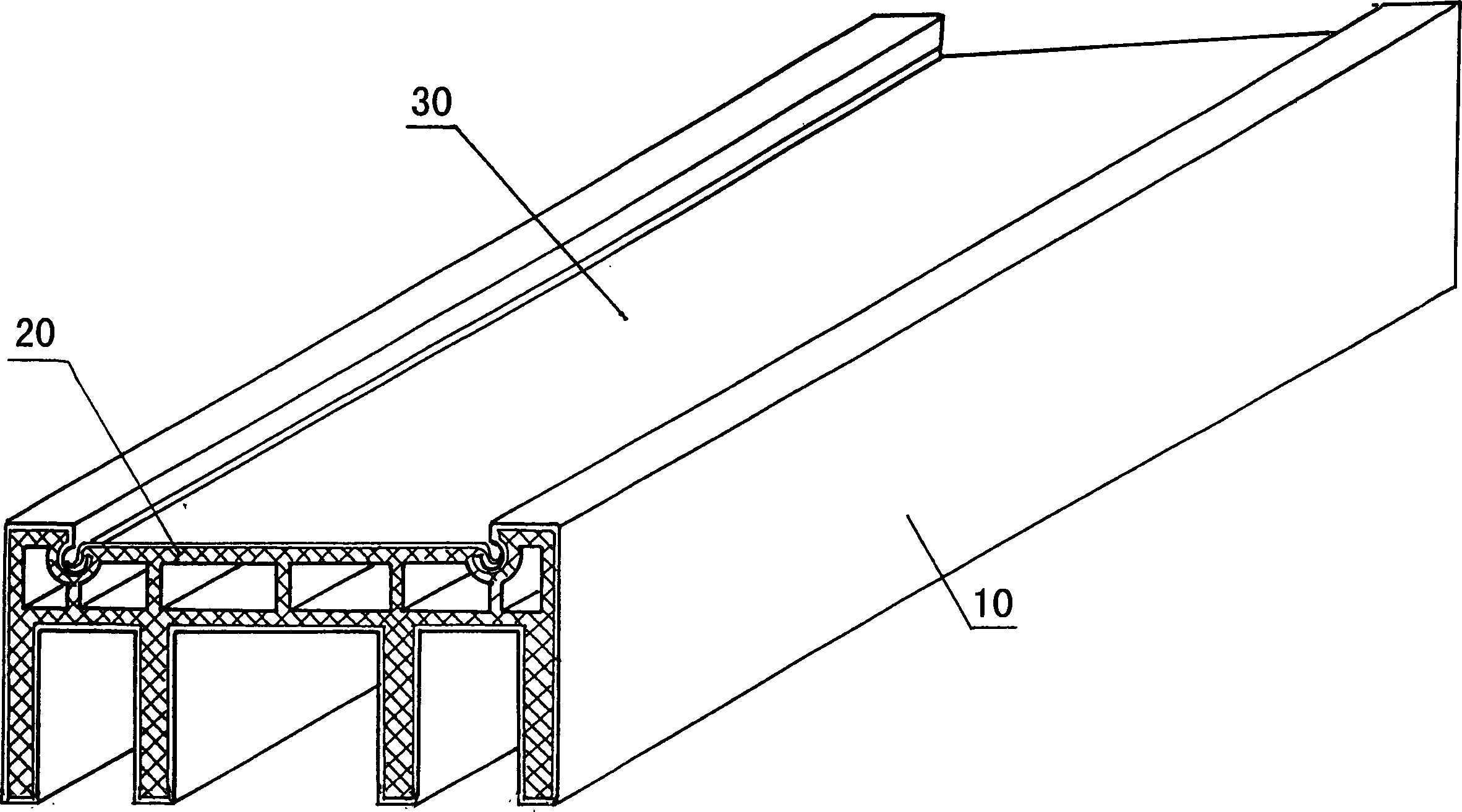

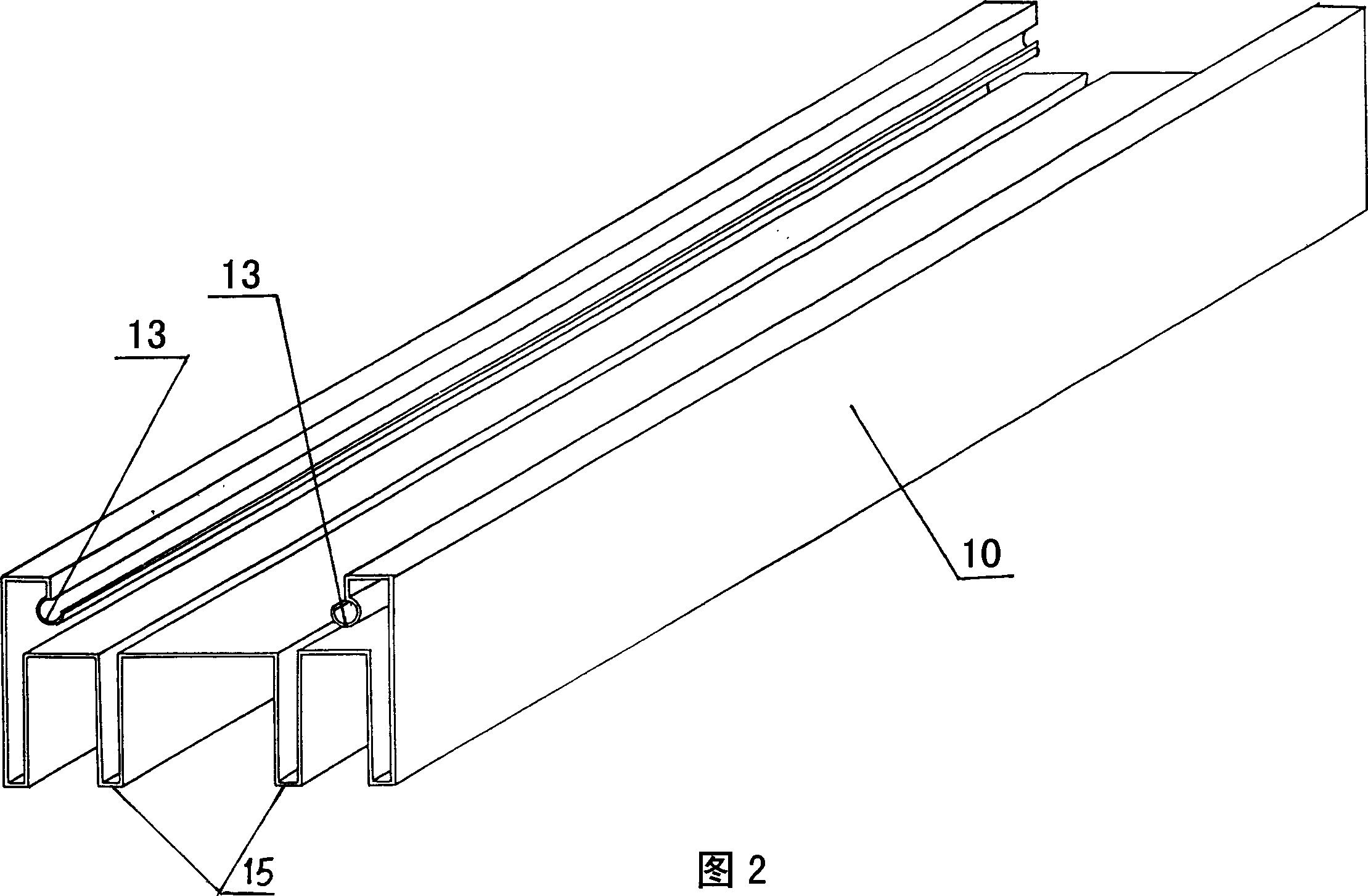

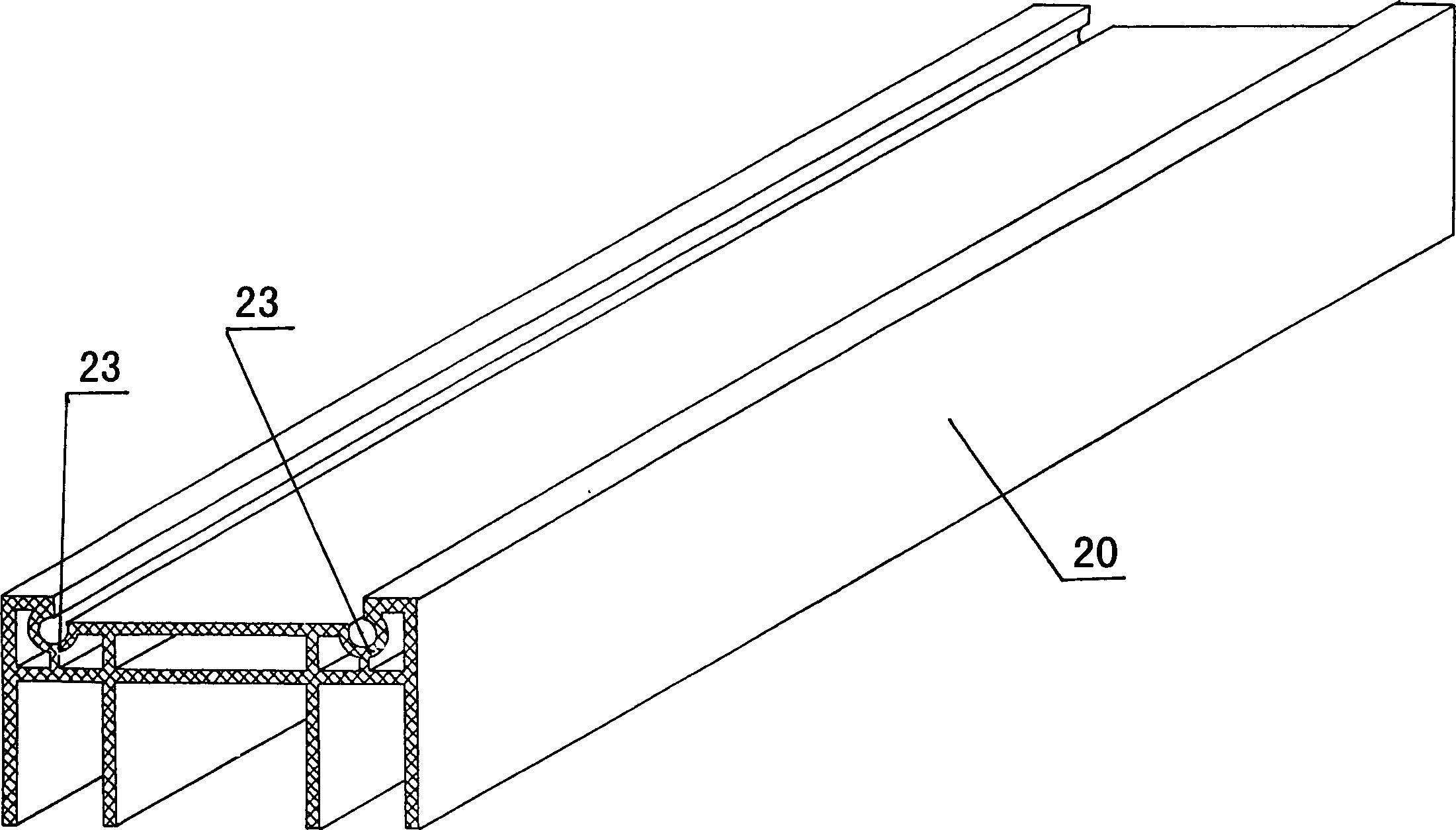

[0049] figure 1 It is an example of the stainless steel-lined plastic door and window profile of the present invention, and it is a window frame profile for making sliding windows that has been combined and shaped, as shown in Fig. 2 to Figure 4 is a perspective view of its main components. The cavity of the stainless steel cavity cover 10 matches the cross-sectional profile shape of the lining plastic skeleton 20, and the latter is sleeved in the cavity of the former. The fastening sides of the stainless steel cavity cover 10 are parallel to each other to form an opening, and the fastening sides are a pair of symmetrical primary arc buckles 13 . In the corresponding position of the lining plastic frame 20, there are two circular arc fastening grooves 23. The fastening edges on the left and right sides of the stainless steel sealing plate 30 are secondary arc buckles 33 . After the profiles of the present invention are assembled and buckled into shape, the primary arc buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com