Magnetron

A magnetron and magnetic pole technology, applied in the field of magnetron, can solve problems such as deterioration of magnetron oscillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

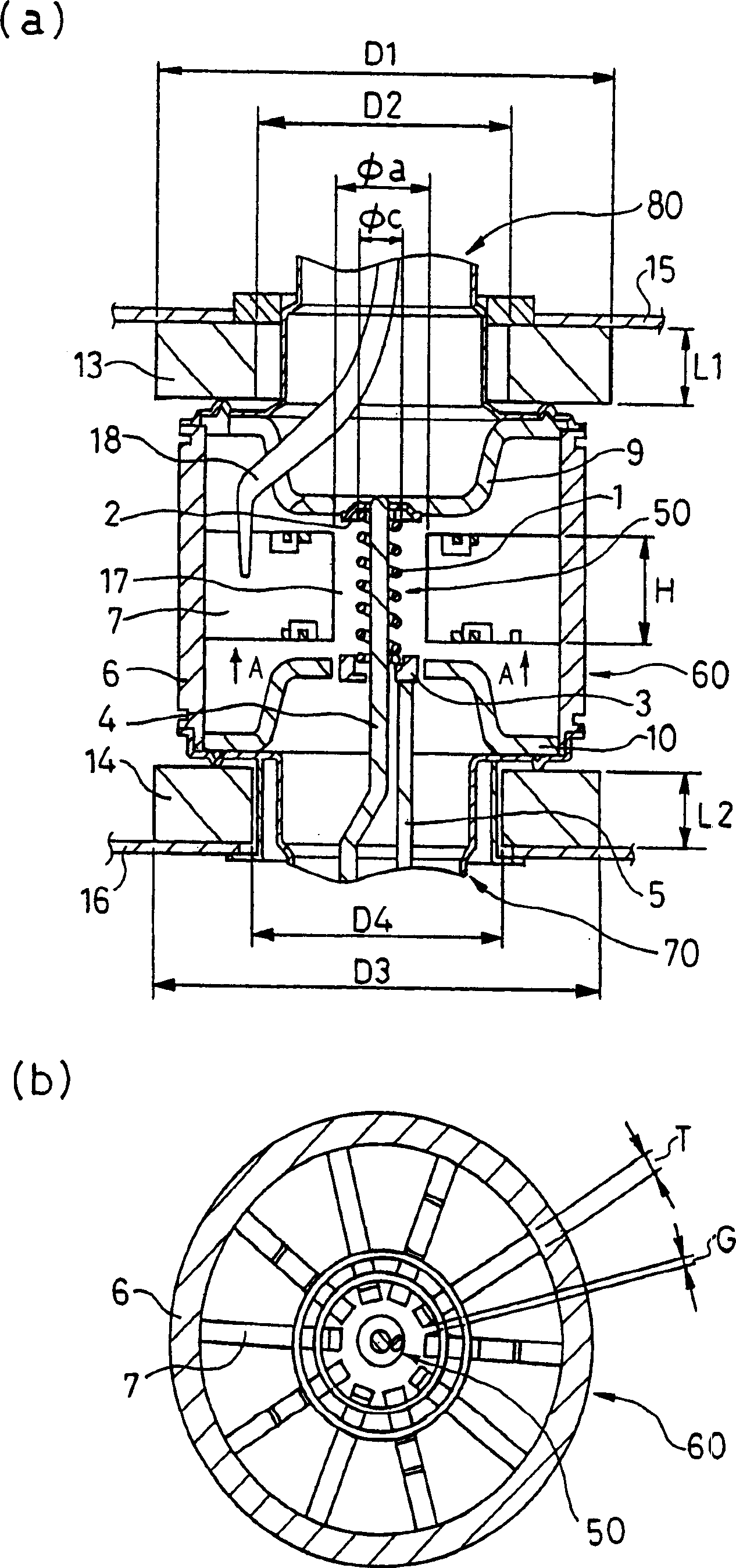

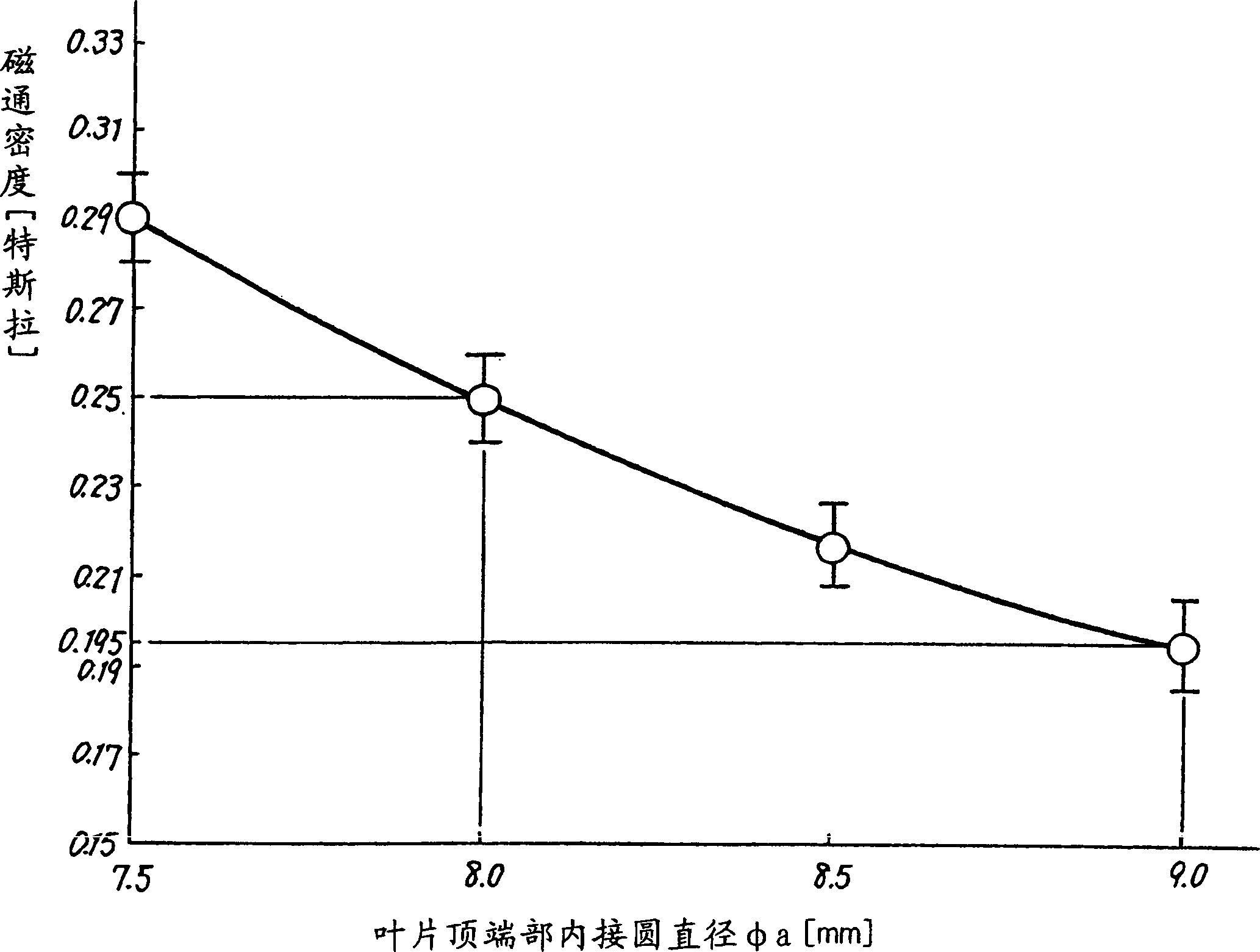

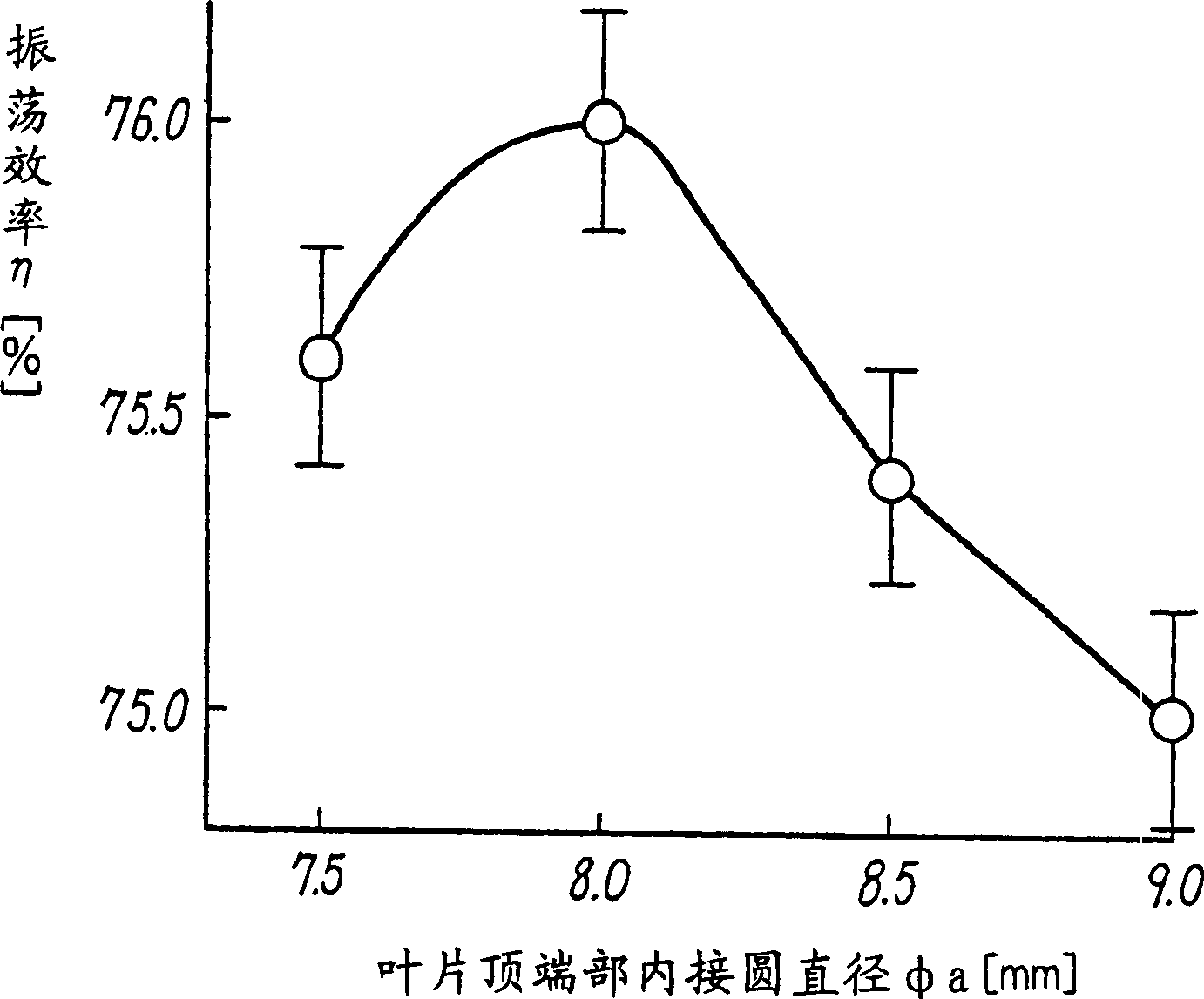

[0056] figure 1 It is an enlarged sectional view showing a main part of the magnetron according to Embodiment 1 of the present invention. figure 1 (a) is the side sectional view of the magnetron of embodiment 1, figure 1 (b) means from figure 1 (a) Cross-sectional view of the anode part and the like viewed in the direction of arrow A.

[0057] like figure 1 As shown, the cathode part 50 is arranged in the central part of the magnetron, and the anode part 60 is arranged around it. The cathode portion 50 is composed of a filament 1 and a central lead 4 and a side lead 5 connected by end caps 2 and 3 provided at both ends of the filament 1 . The center lead 4 is disposed substantially on the central axis of the coiled filament 1 . The anode part 60 is a cylindrical anode cylinder 6 arranged substantially coaxially with the filament 1, and is provided so as to protrude from the inner peripheral surface of the anode cylinder 6 to the filament 1 and arranged so that its ti...

Embodiment 2

[0079] Below, while referring to the attached Figure 1 Next, the magnetron of the second embodiment of the present invention will be described.

[0080] Figure 7 It is an enlarged cross-sectional view showing main parts of the magnetron according to Embodiment 2 of the present invention. Figure 7 (a) is the side sectional view of the magnetron of embodiment 2, Figure 7 (b) means from Figure 7 (a) Cross-sectional view of the anode part, etc. viewed from the arrow A direction.

[0081] like Figure 7 As shown, the cathode part 150 is arranged in the central part of the magnetron, and the anode part 160 is arranged around it. The cathode part 150 is composed of a filament 101 and a central lead 104 and a side lead 105 connected by end caps 102 and 103 provided at both ends of the filament 101 . The anode part 160 is formed by a cylindrical anode cylinder 106 and a plurality of blades 107 protruding from the inner peripheral surface of the anode cylinder 106 to the fila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com