Low-carbon low-alloy steel and pipe

A low-alloy steel and steel-grade technology, applied in the field of low-carbon low-alloy steel and its pipes, to achieve the effects of small deformation resistance, low carbon content, and low alloy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] According to the weight percentage of the chemical composition designed in the present invention and 150 tons of a batch of steel produced by electric furnace continuous casting in the electric furnace branch factory of Baosteel Steelmaking Department, rolled into steel pipes of 139.70*7.72 in the steel pipe branch company of Baosteel Co., Ltd., and according to different The tempering system is processed into X60~X80 steel grade line pipe. Randomly take two pipes to analyze the composition of the finished product. The specific chemical composition is as follows:

[0050]weight percentage

[0051] element

[0052] Analysis 1 Analysis 2

[0053] C 0.151 0.146

[0054] Si 0.229 0.232

[0055] Mn 1.108 1.101

[0056] P 0.007 0.010

[0057] S 0.003 0.005

[0058] V 0.089 0.085

[0059] Al 0.023 0.022

[0060] Ni 0.062 0.072

[0061] Cu 0.044 0.044

[0062] B 0.0019 0.0019 Others (Fe and impurities) Remaining amou...

Embodiment 2

[0077] According to the chemical composition weight percentage designed by the present invention and 150 tons of a batch of steel produced by electric furnace continuous casting in the electric furnace branch factory of Baosteel Steelmaking Department, rolled into steel pipes of 139.70*9.17 in the steel pipe branch company of Baosteel Co., Ltd., and according to different The tempering system is processed into X60~X80 steel grade line pipe. Randomly take two pipes to analyze the composition of the finished product. The specific chemical composition is as follows:

[0078] weight percentage

[0079] element

[0080] Analysis 1 Analysis 2

[0081] C 0.148 0.144

[0082] Si 0.267 0.259

[0083] Mn 1.077 1.081

[0084] P 0.011 0.011

[0085] S 0.006 0.005

[0086] V 0.110 0.112

[0087] Al 0.028 0.029

[0088] Ni 0.013 0.014

[0089] Cu 0.086 0.095

[0090] B...

Embodiment 3

[0117] According to the weight percentage of the chemical composition designed in the present invention, it is smelted in a small furnace in the steelmaking workshop of the product room of Baosteel Technology Center, and finally formed into plates with a thickness of 20mm and 30mm after forging and rolling. The specific chemical composition is as follows:

[0118] weight percentage

[0119] element

[0120] 20mm 30mm

[0121] C 0.164 0.156

[0122] Si 0.276 0.269

[0123] Mn 1.197 1.220

[0124] P 0.007 0.006

[0125] S 0.005 0.005

[0126] V 0.089 0.085

[0127] Al 0.008 0.012

[0128] Ni 0.089 0.085

[0129] Cu 0.069 0.081

[0130] B 0.0017 0.0019

[0131] Others (Fe and impurities) remaining amount remaining amount

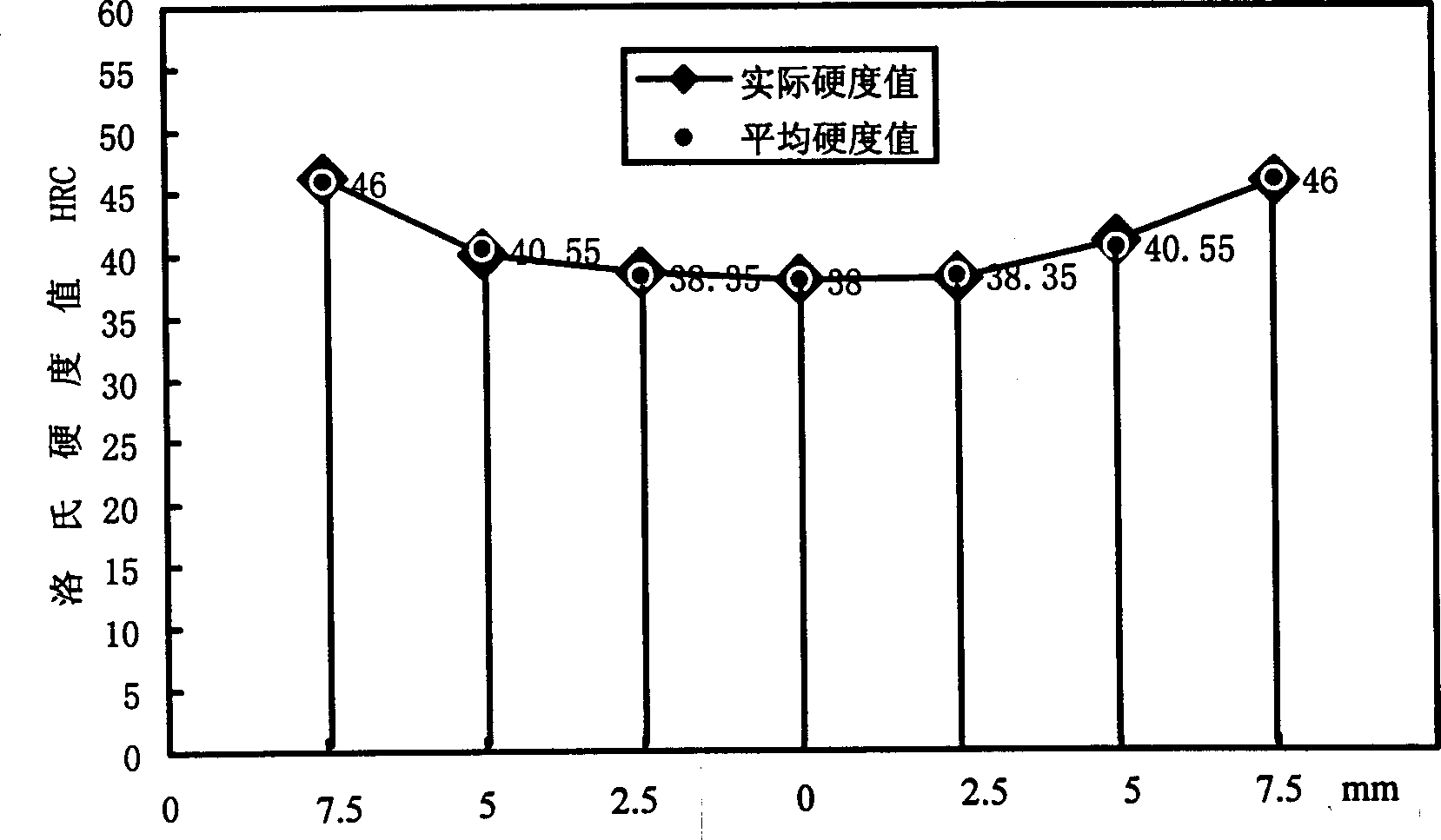

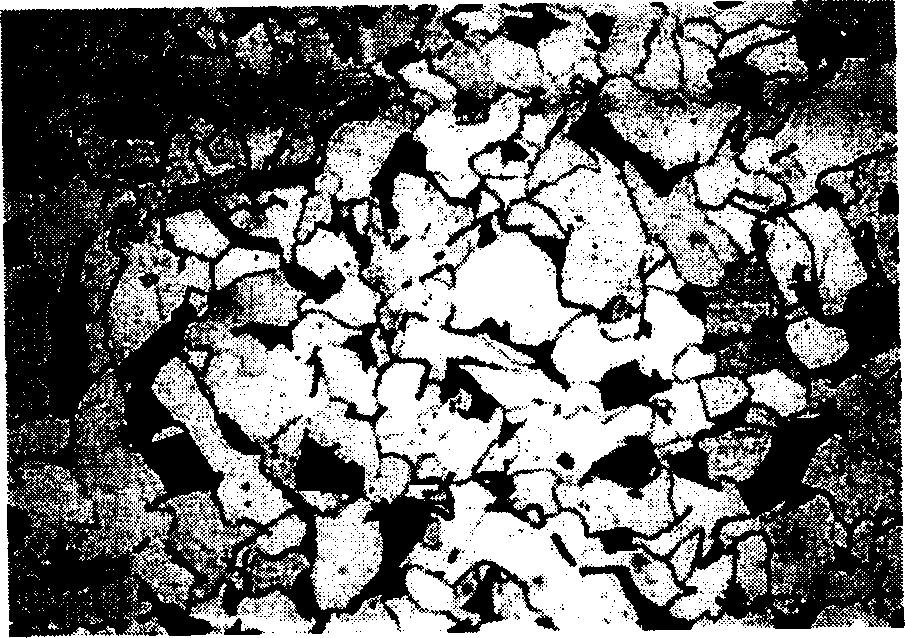

[0132] After quenching at 910°C, when the tempering temperature is 700°C, the physical quality is shown in the table below, which meets the requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com