Combined sewage treating process and apparatus

A sewage treatment and combined process technology, applied in the direction of aerobic process treatment, sustainable biological treatment, mixer, etc., can solve the problems of limited sewage treatment process application, poor sewage treatment effect, oxygenation effect needs to be improved, etc., to improve Sewage purification efficiency, saving investment and maintenance costs, good effect of sludge settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

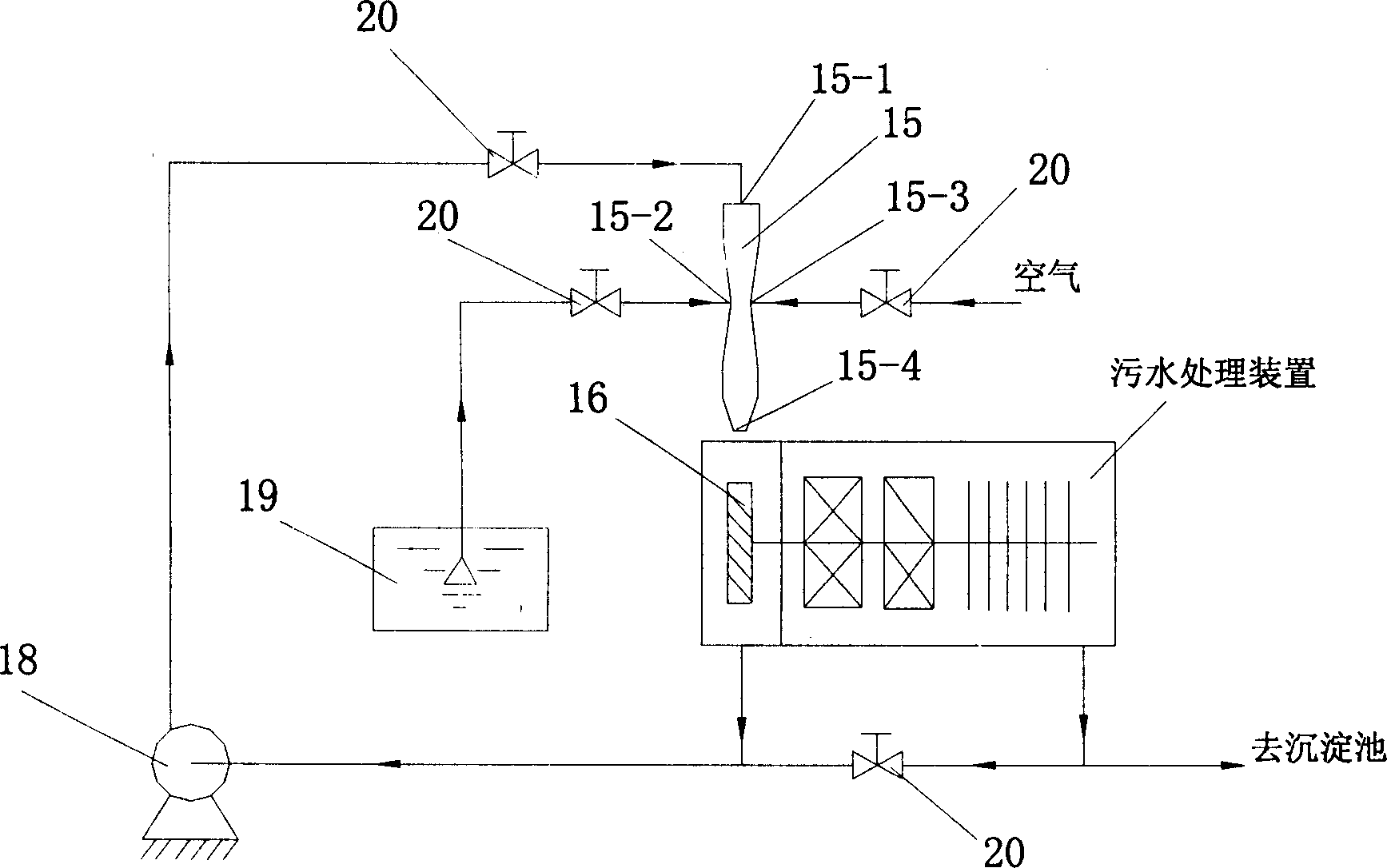

[0028] figure 1 Show the specific process of the present invention, by figure 1 It can be seen that the sewage treatment combined system includes a sewage pump 18, a sewage pool 19, a sewage treatment device, a valve 20, etc., wherein the sewage treatment device includes a jet injector 15, and the jet injector 15 includes a water inlet 15-1 and a water suction port 15-2, an air suction port 15-3 and a jet port 15-4; wherein, the water flow inlet 15-1 is connected to the sewage pump 18 through the valve 20, and the water suction port 15-2 is connected to the sewage pool 19 through the valve 20 , the air suction port 15-3 communicates with the atmosphere through the valve 20, and the jet port 15-4 is opposite to the runner 16 of the sewage treatment device; the specific process is: under the power of the sewage pump 18, the jet injector 15 At the same time as the sewage in the sewage tank 19, the air is sucked in through the air suction port 15-3, and the air and water are mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com