Dynamic shock-absorber in CRT

A technology of cathode ray tube and shock absorber, applied in the direction of cathode ray tube/electron beam tube, discharge tube, electrical components, etc., can solve the problems of unsuitability for mass production and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Detailed description of the preferred embodiment

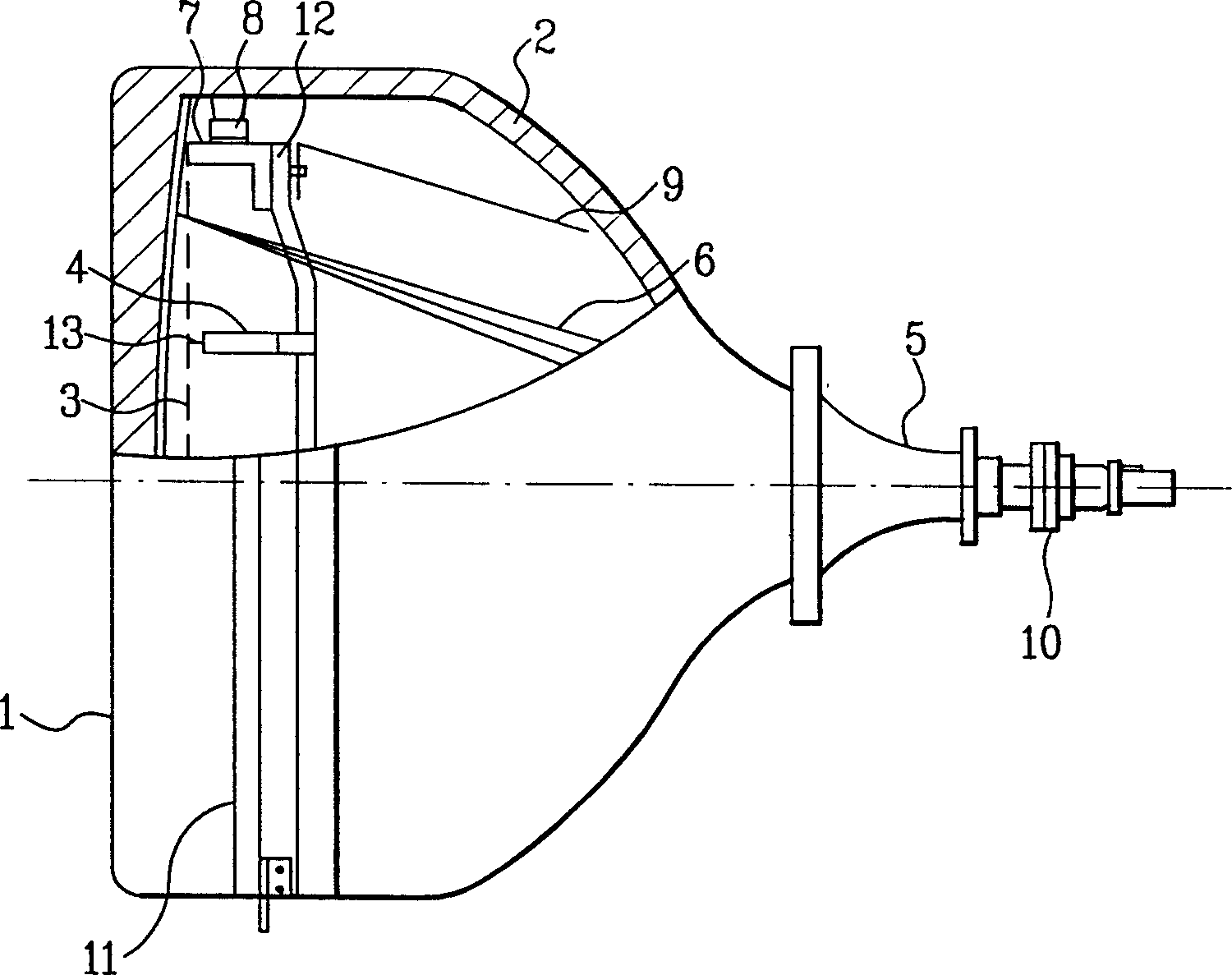

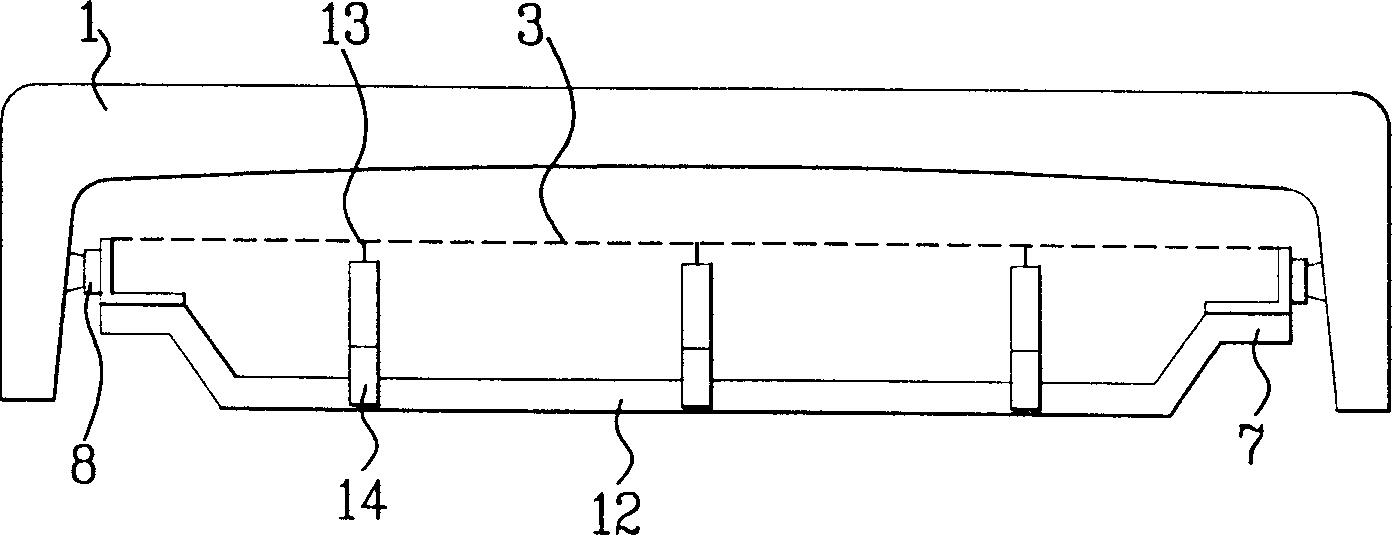

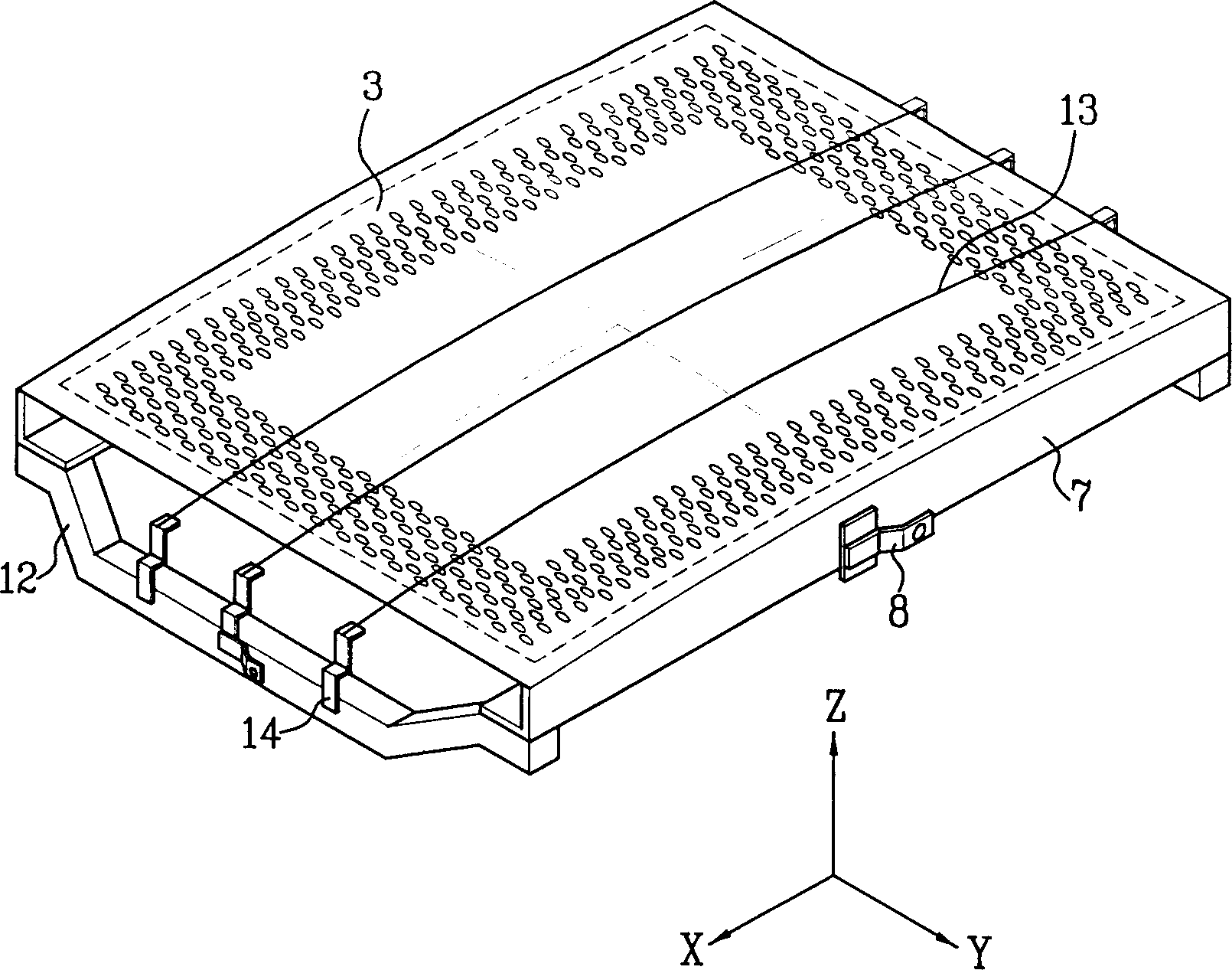

[0052] Referring to the details of the preferred embodiments of the present invention, the embodiments will be described in conjunction with the accompanying drawings. The dynamic damper in the cathode ray tube of the present invention will be referred to Figure 8 to Figure 10 Be explained.

[0053] The dynamic damper in the cathode ray tube of the present invention includes a base portion 110 and a vibration damping portion 120 . The base part 110 bears the vibration of the shadow mask 3, connects the vibration damping part 120 to the base part 110, and adjusts the natural frequency of the vibration damping part 120 to the natural frequency of the shadow mask 3, thereby actually absorbing the vibration. Preferably, the base part 110 and the vibration-damping part 120 are integrally made by stamping or sheet metal process. Also, it is preferable to manufacture the base portion 110 and the damping portion 120 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com