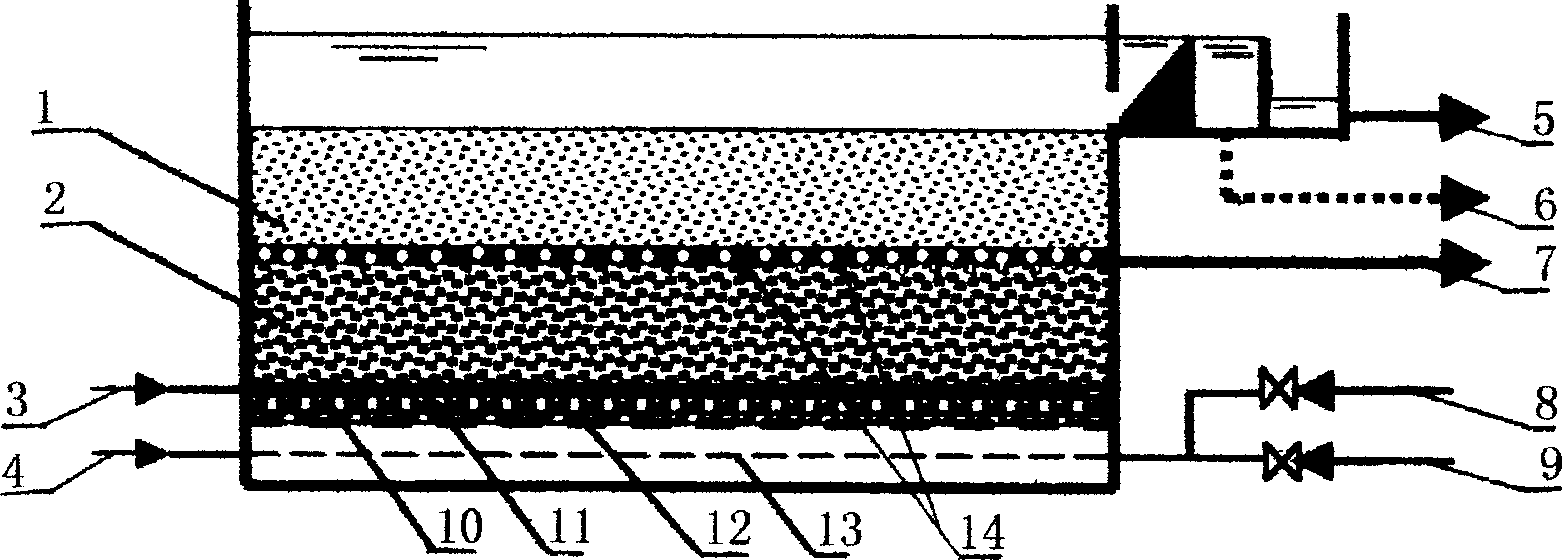

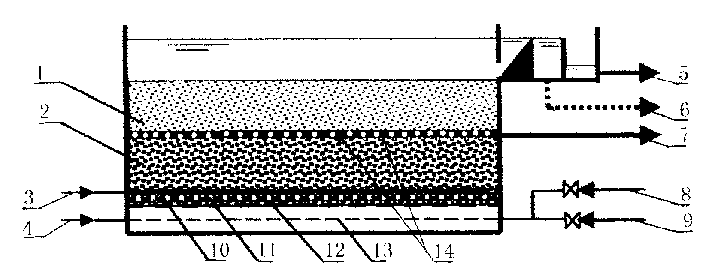

Double-layer filter material biological aeration filter pond

A biological aerated filter, double-layer filter material technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of long backwashing time, uneconomical, large load and other problems, to achieve the effect of reducing the loss of backwash resistance, reducing the water consumption of backwashing, and reducing operating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Treatment of low-concentration domestic sewage (COD concentration is 100-250mg / l): the particle size of the lower filter material is 4-6mm, and the density is (1800-2200) kg / m 3 , the height is 1-1.5m; the upper filter material is 2-3mm, and the density is (1800~2200)kg / m 3 , the height is 2-3m. The operating water flow rate is 2-3m / h, and the water-gas ratio is 1:3~1:6. This process adopts the method of alternating large and small backwashes for backwashing, and a large backwash is performed after about 5-7 small backwashes. Both large and small backwashing adopt air-water combined backwashing method. The removal rate of suspended solids is about 80%, the removal rate of COD is about 80%, and the removal rate of ammonia nitrogen is 80-95%.

Embodiment 2

[0024] Treatment of extremely low-concentration domestic sewage (COD concentration 3 , the height is 1-1.5m; the upper filter material is 1-3mm, and the density is (1800~2200)kg / m 3 , the height is 2-3m. The operating water flow rate is 3-6m / h, and the water-gas ratio is 1:2-1:4. This process adopts the method of alternating large and small backwashes for backwashing, and after about 5-7 small backwashes, a large backwash is performed. Both large and small backwashing adopt air-water combined backwashing method. The removal rate of suspended solids is about 80%, the removal rate of COD is about 80%, and the removal rate of ammonia nitrogen is 80-95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com