Energy-saving decompression gas supply method for natural gas and its equipment

A technology for natural gas and pressure relief, which is applied to container discharge methods, pressure vessels, fixed-capacity gas storage tanks, etc., can solve the problem of "unclean unloading of skid trucks, and achieve the effect of improving utilization efficiency and simple process."

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

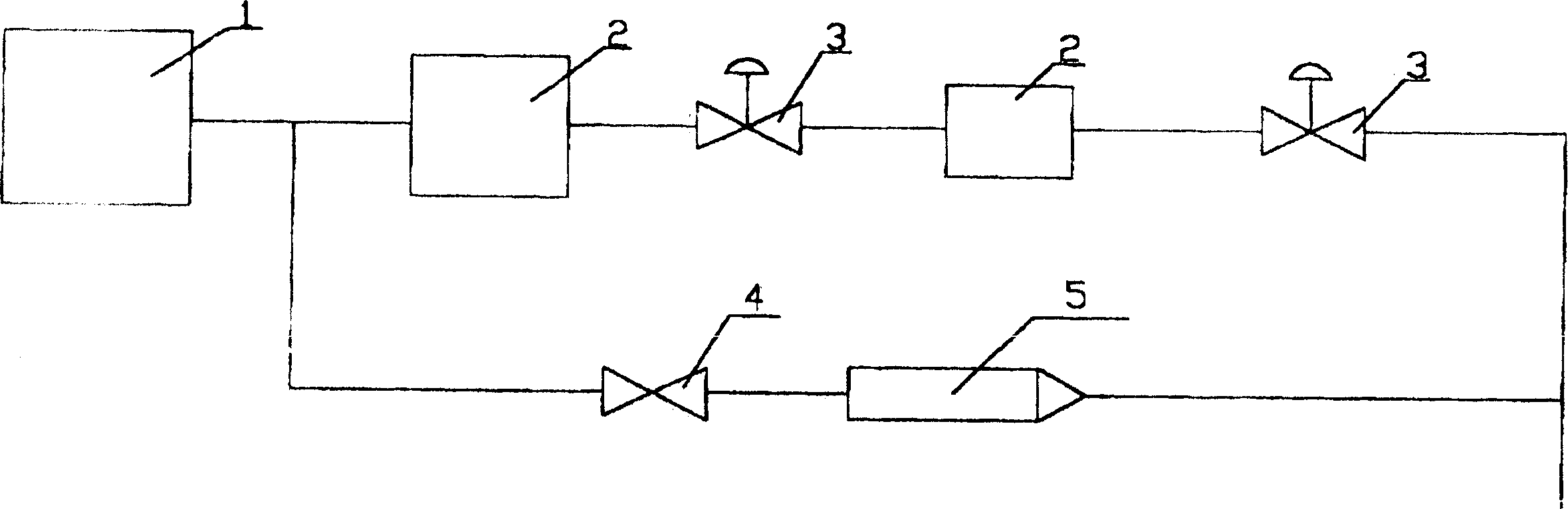

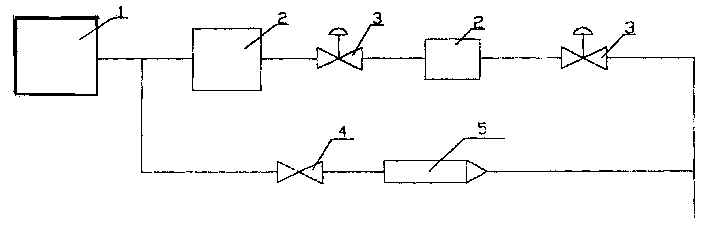

[0012] Embodiment: a kind of energy-saving pressure relief gas supply method of natural gas (see figure 2) , including two-stage pressure regulation and two-time temperature compensation process of natural gas skid truck unloading, which is characterized in that a nozzle pressure relief bypass with valve is connected in parallel at the same time as the two-stage pressure regulation and two-time temperature compensation process, when The pressure inside the skid car is reduced to 15kgf / cm 2 At this time, open the valve of the pressure relief bypass to start the nozzle, so that the pressure inside the skid car will increase from 15kgf / cm 2 down to 5kgf / cm 2 , thus leaving about 60Nm in the skid car 3 of natural gas.

[0013] A device cooperating with the above natural gas energy-saving pressure relief gas supply method (see figure 2) , including a two-stage series pressure regulator 3 connected to the output end of the natural gas skid truck 1 unloading and a related two-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com