Mn-Zn ferrite

A ferrite, manganese-zinc technology, applied in the direction of inorganic material magnetism, etc., can solve the problem of not being able to obtain high magnetic permeability characteristics at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

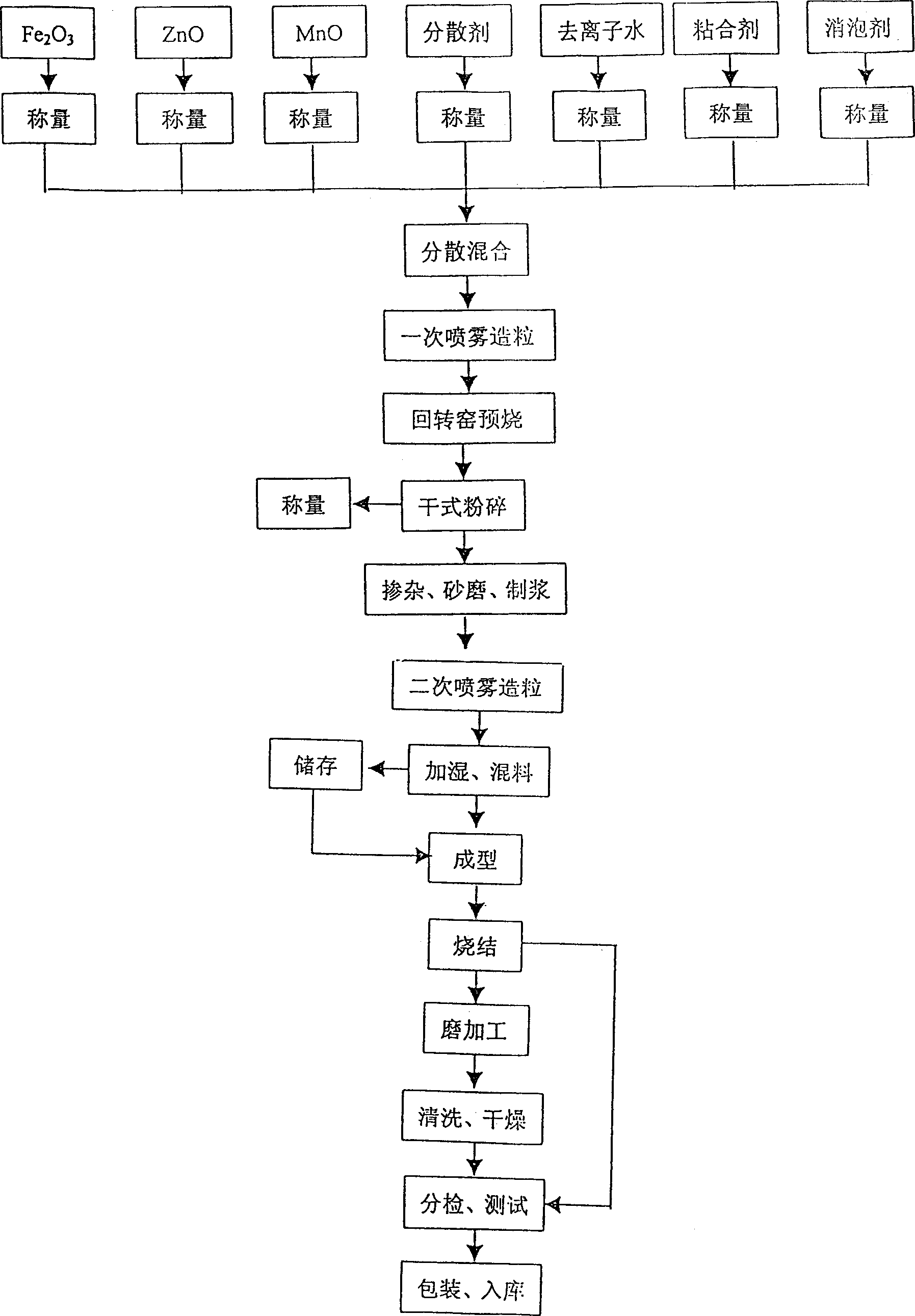

Method used

Image

Examples

Embodiment 1

[0022] Will Fe 2 o 3 (53.5 mole %), MnO (26 mole %) and ZnO (20.5 mole %) as main components, add dispersant simultaneously: polypropionic acid: 0.5 weight %, defoamer: n-octanol: 0.2 weight %, deionized water 95% by weight. After mixing them, add binder: polyvinyl alcohol: 0.8% by weight solution, mix in a high-speed mixer for 70-80 minutes, and make an average particle size of 100 microns by spray drying machine, moisture below 0.1%, and flow Particles with an angle of less than 40 degrees; pre-fired in a rotary kiln, pre-fired temperature: 800-980 ° C, pre-fired time: 5 minutes to 2 hours; 3. Dry or wet crushing for 25-35 minutes, Made into an average particle size of 1.5-2.0 microns; adding additive ingredients: calcium oxide (CaO): 0.02% by weight, silicon dioxide (SiO 2 ): 0.01% by weight, niobium oxide (Nb 2 o 5 ): 0.03% by weight, tantalum oxide (Ta 2 o 5 ): 0.03% by weight, zirconia (ZrO 2 ): 0.04% by weight, hafnium oxide (HfO 2 ): 0.04% by weight, the above...

Embodiment 2

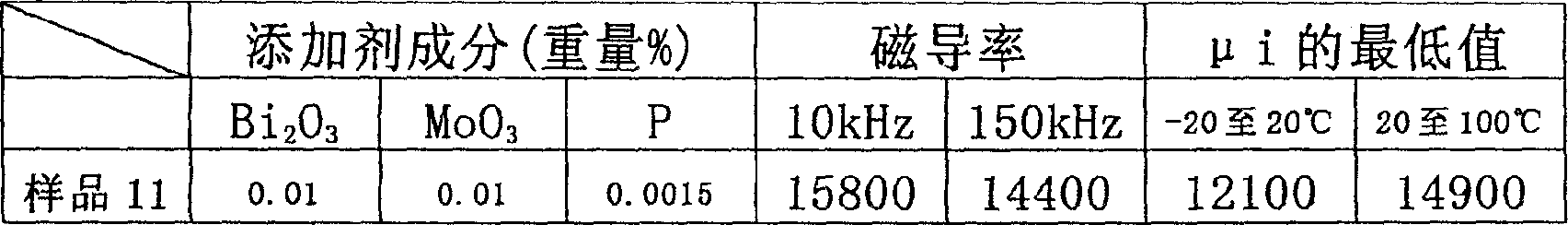

[0041] In the composition of manganese-zinc ferrite, Fe 2 o 3 (50 mol%), MnO (22 mol%), ZnO (16 mol%) as the main components, and the relative main components as additive components except CaO and SiO 2 , also contains Bi 2 o 3 、MoO 3 and P adopt the preparation method in Example 1 to obtain samples 11-16; containing Bi 2 o 3 and P give samples 17 and 18, and only P gives sample 19. As a comparative sample 20-22 is made Bi 2 o 3 、MoO 3 And the addition of P is prepared outside the above range.

[0042] Each obtained sample was evaluated similarly to Example 1. The results are listed in Table 2

[0043] Sample 12

[0044] *) means outside the range and preferred range of the present invention.

Embodiment 3

[0046] In the composition of manganese-zinc ferrite, Fe 2 o 3 (55 mol%), MnO (25 mol%), and ZnO (18 mol%) are the main components, and the main components are additive components except CaO and SiO 2 , also contains In 2 o 3 、MoO 3 and P adopt the method that embodiment 1 makes to make sample 23-28; Contain In 2 o 3 and P gave samples 29 and 30, and only P gave sample 31. As comparative samples 32-34 are made In 2 o 3 、MoO 3 And the addition of P is prepared outside the above range.

[0047] Each obtained sample was evaluated similarly to Example 1. The results are listed in Table 3

[0048] table 3

[0049] *) means outside the range and preferred range of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com