Macroporous resin adsorption process of extracting chlorogenic acid in high content

A macroporous resin and adsorption extraction technology, which is applied in the field of extracting high-content chlorogenic acid, can solve the problems of chlorogenic acid products that have not yet been seen on the market, and achieve the effect of reliable material technology foundation, improved antibacterial ability, and increased income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

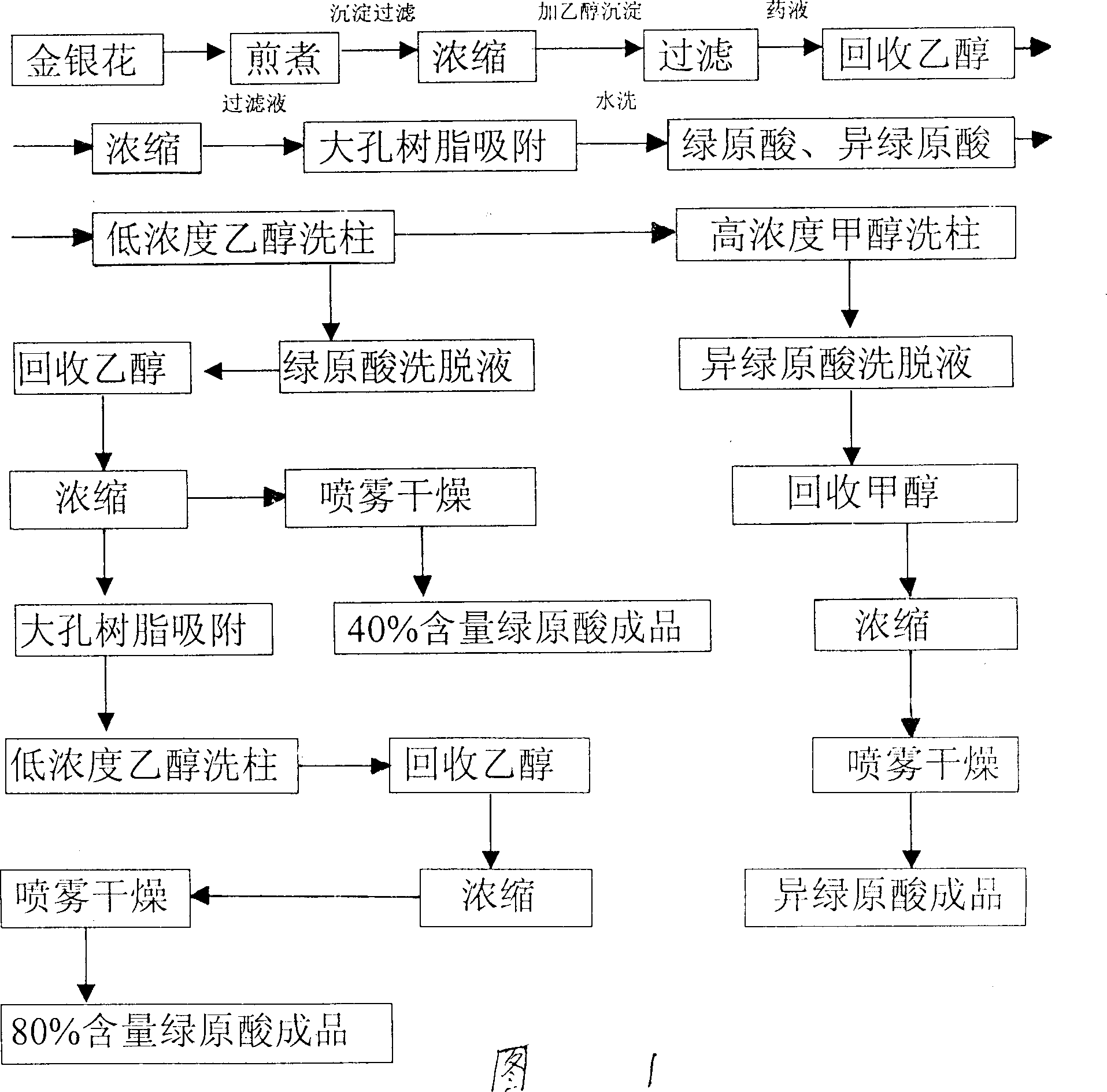

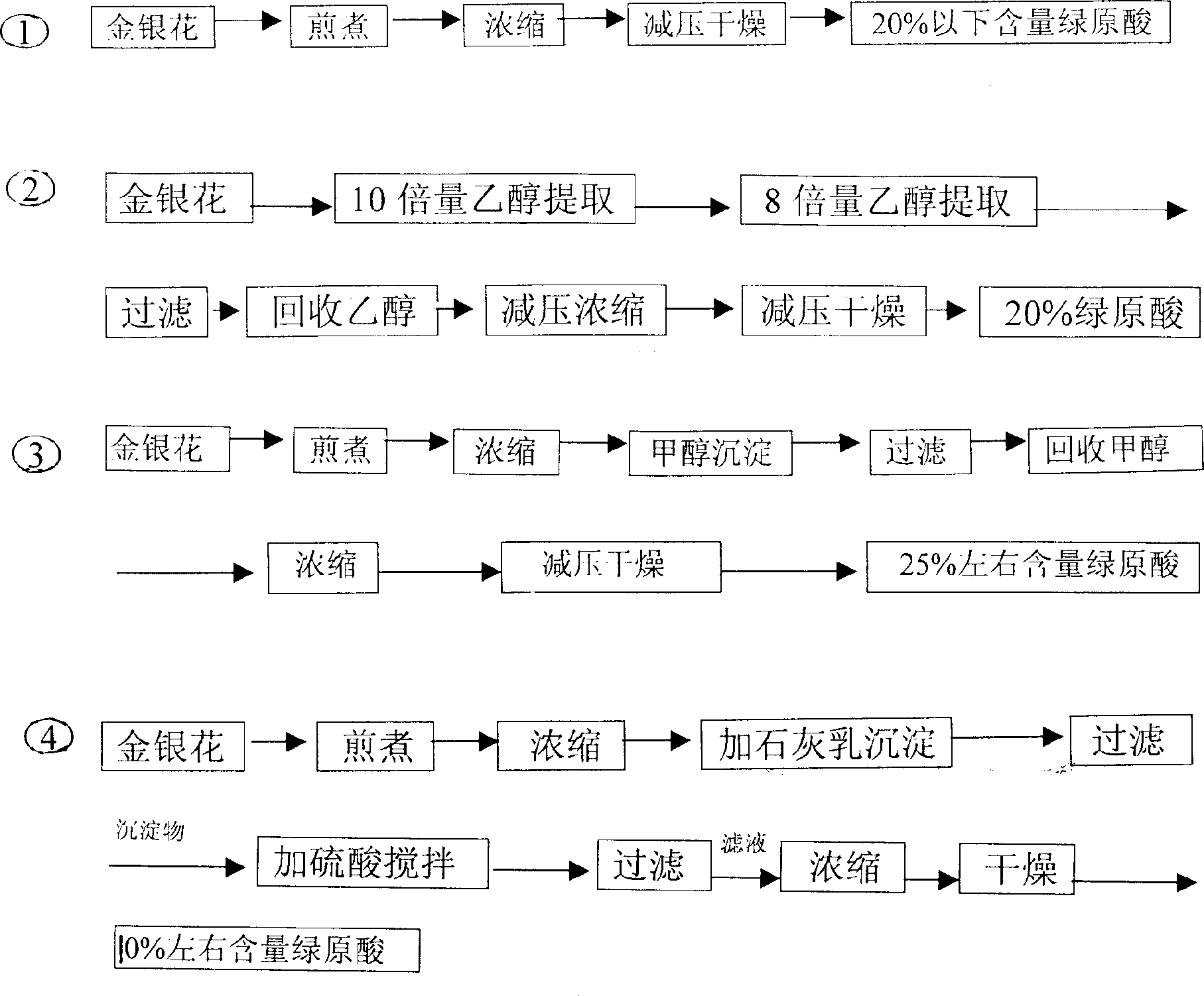

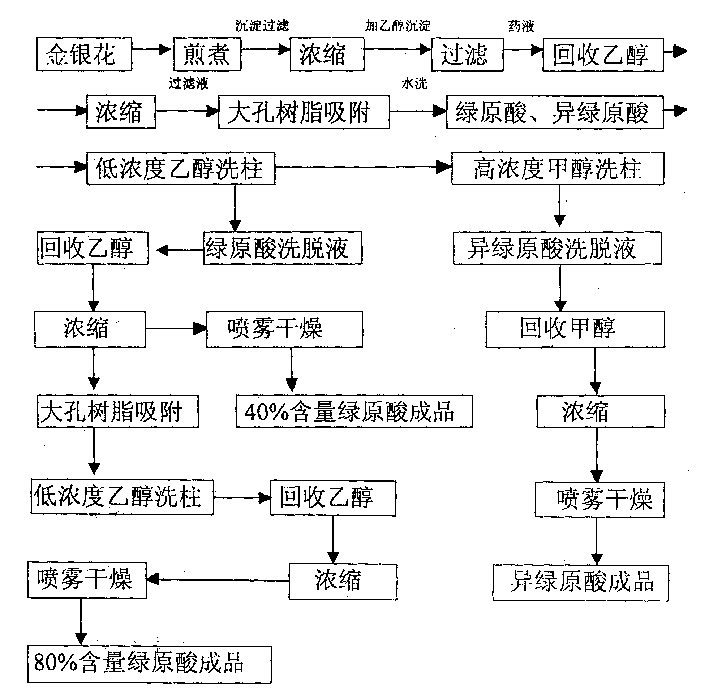

[0008] The process for the adsorption and extraction of high content of chlorogenic acid by macroporous resin consists of the crushing of raw materials of honeysuckle, the extraction process of water extract containing chlorogenic acid, and the separation process of adsorption of high content of chlorogenic acid by macroporous resin; The raw material crushing process of honeysuckle is to pulverize the honeysuckle into honeysuckle particles with a particle size of less than 4mm with a sieve grinder with an aperture of 4mm; the extraction process of the water extract containing chlorogenic acid is as follows: decoct the honeysuckle particles with water for three times. The weight ratio of honeysuckle to water for the first time is 1:5, decocted for 2 hours, and the liquid is taken; the weight ratio of the second time and the third time of water decocted is 1:3, respectively, decocted for 30 minutes, and decocted for three times. The boiled medicinal solution is combined, the superna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com