Engineering method for separating and extracting xanthan gum

A xanthan gum and separation process technology, applied in the engineering field of xanthan gum separation and extraction, can solve the problems of increasing the risk of explosion and fire at the production site, large fluctuations in product quality, and large consumption of organic solvents, etc., to achieve safety in the production process Reliable, saving equipment and plant investment, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

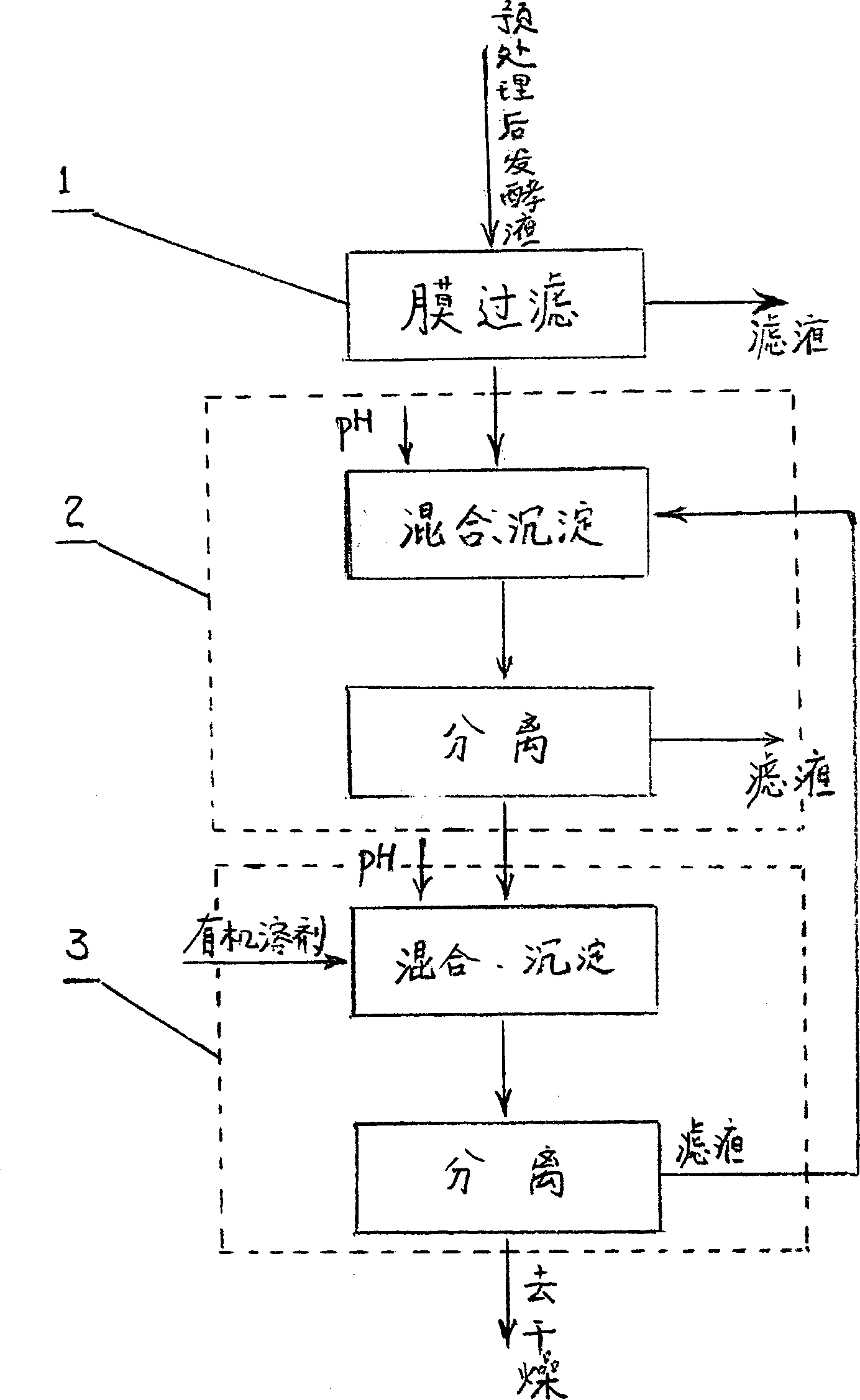

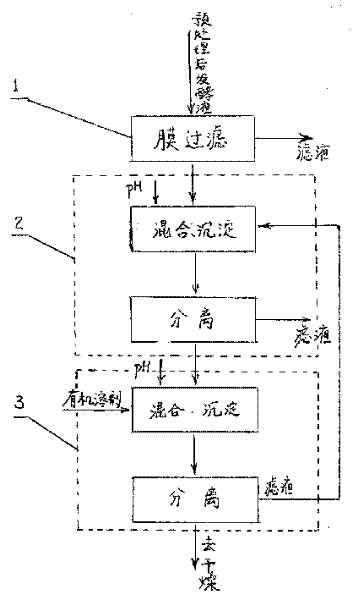

[0013] Such as figure 1 As shown, the pretreated fermentation broth is first passed through the membrane filtration device 1, and concentrated by ultrafiltration using membrane separation technology to remove part of the water and impurities; then in the first unit 2, it is mixed and precipitated with an organic solvent instantaneously, and the pH is adjusted at the same time. Value; After separating the filtrate, enter the second unit 3, and then perform a mixing, precipitation and separation operation. In order to reduce the consumption of organic solvent, the filtrate of the second unit 3 can be returned to the first unit 2 to mix with xanthan gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com