Method and device for reproducing data recorded on optical disk

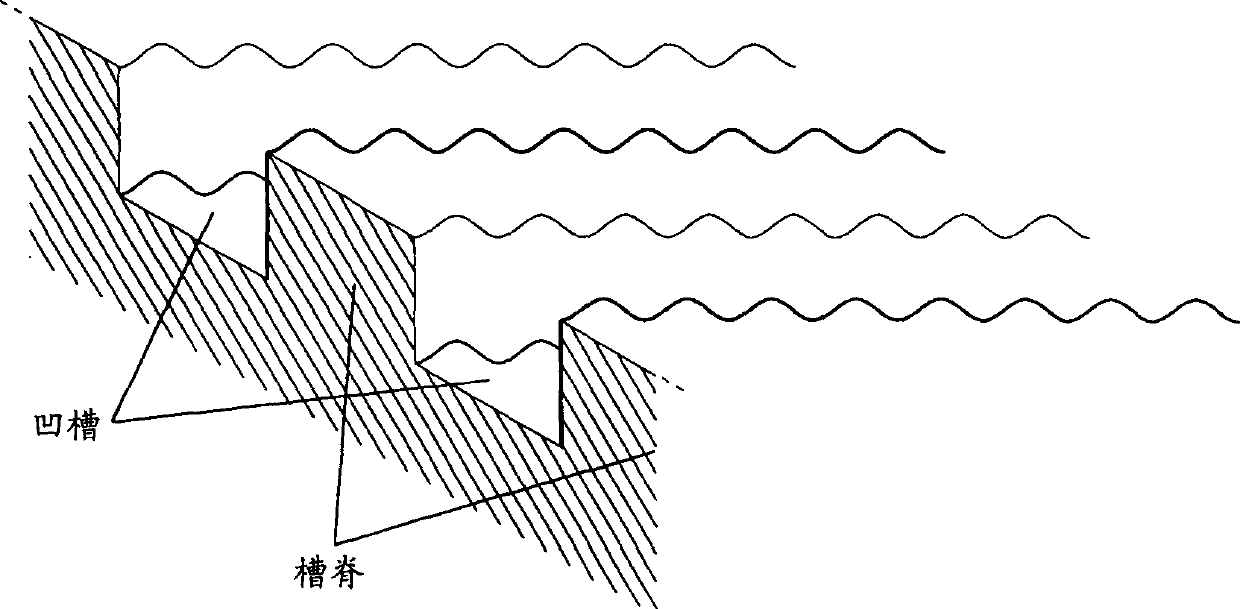

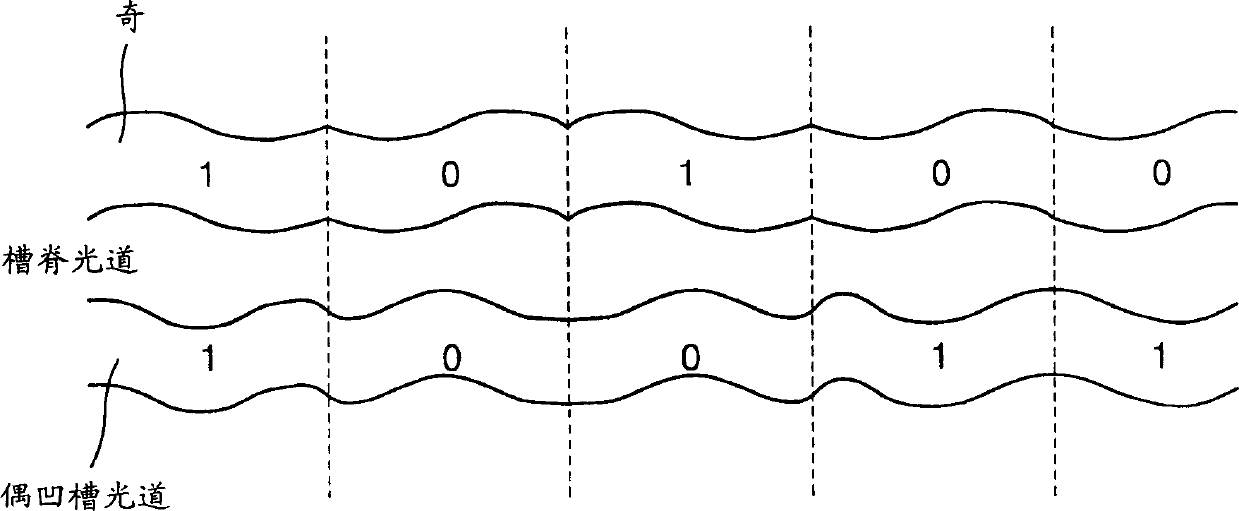

A technology for reproducing optical discs and optical discs, applied in optical recording/reproducing/erasing methods, reproducing non-user data, data recording, etc., capable of solving problems such as track width variation and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

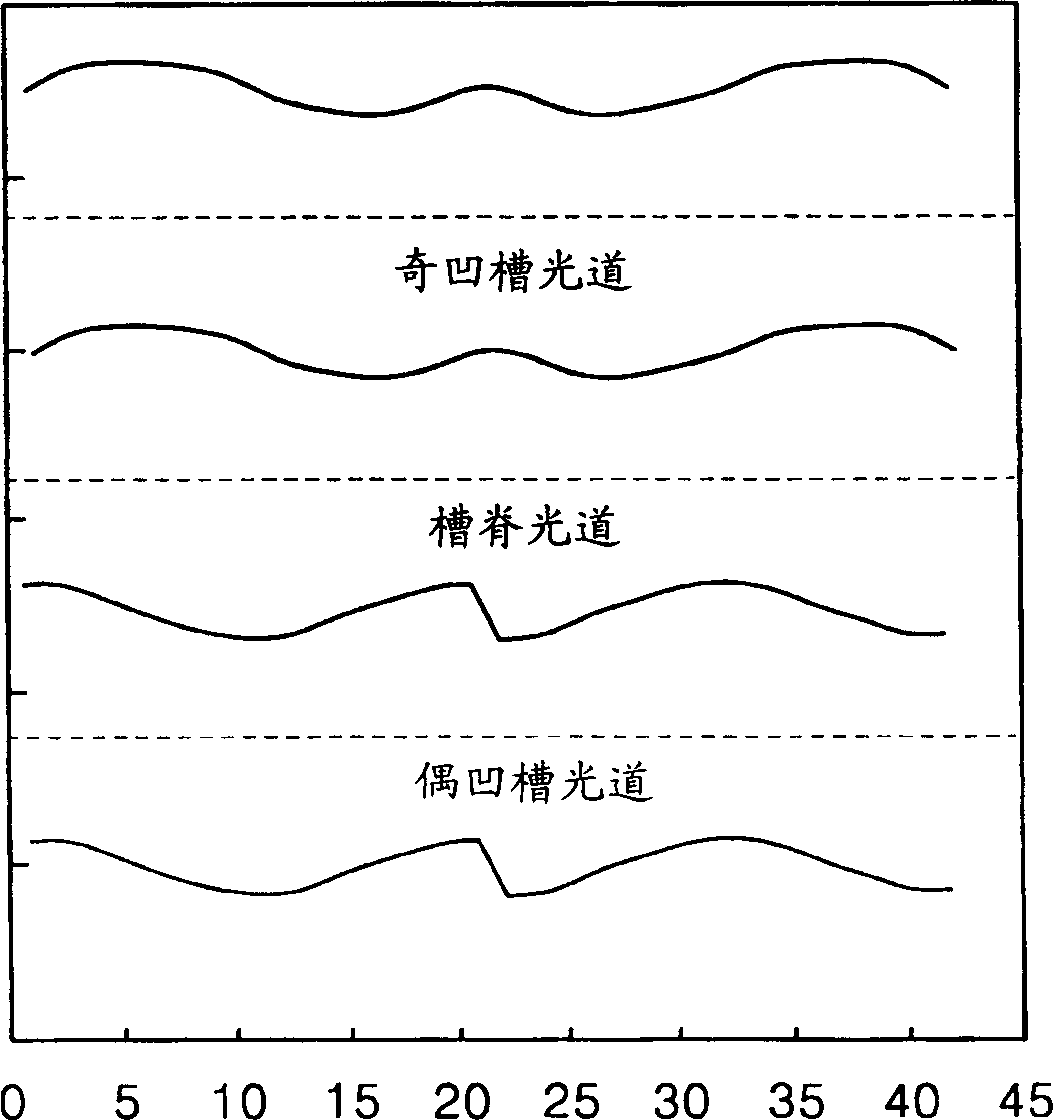

[0049] Referring to FIG. 6, FIG. 6 is a block diagram of a preferred embodiment of an optical disc reproducing apparatus according to the present invention, which includes a beam splitting and detecting unit 10 and a signal processor 20 so as to correct the degradation caused by the variation of the track width. A component of a high-quality reproduction signal is detected in reproduction from an optical disc having a varying track width. The basic structure of an optical pickup is known to those skilled in the art, in which a light beam is emitted onto a recording surface of an optical disc, and a light beam reflected from the recording surface of the optical disc is detected by a beam splitting and detecting unit 10 . Therefore, a detailed description and illustration of the basic structure of the optical pickup is not provided here.

[0050] The beam splitting and detecting unit 10 detects the beam reflected from the recording surface of the optical disc as a central beam p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com