Hanger embedded decorative panel of stone material and its making method

A decorative panel and stone technology, applied in building components, walls, buildings, etc., can solve the problems of unfavorable safety of the main structure of the building, affecting the wide use of stone decorative panels, affecting the decorative effect of stone, etc., to achieve safe and reliable impact resistance performance, Easy and fast installation and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

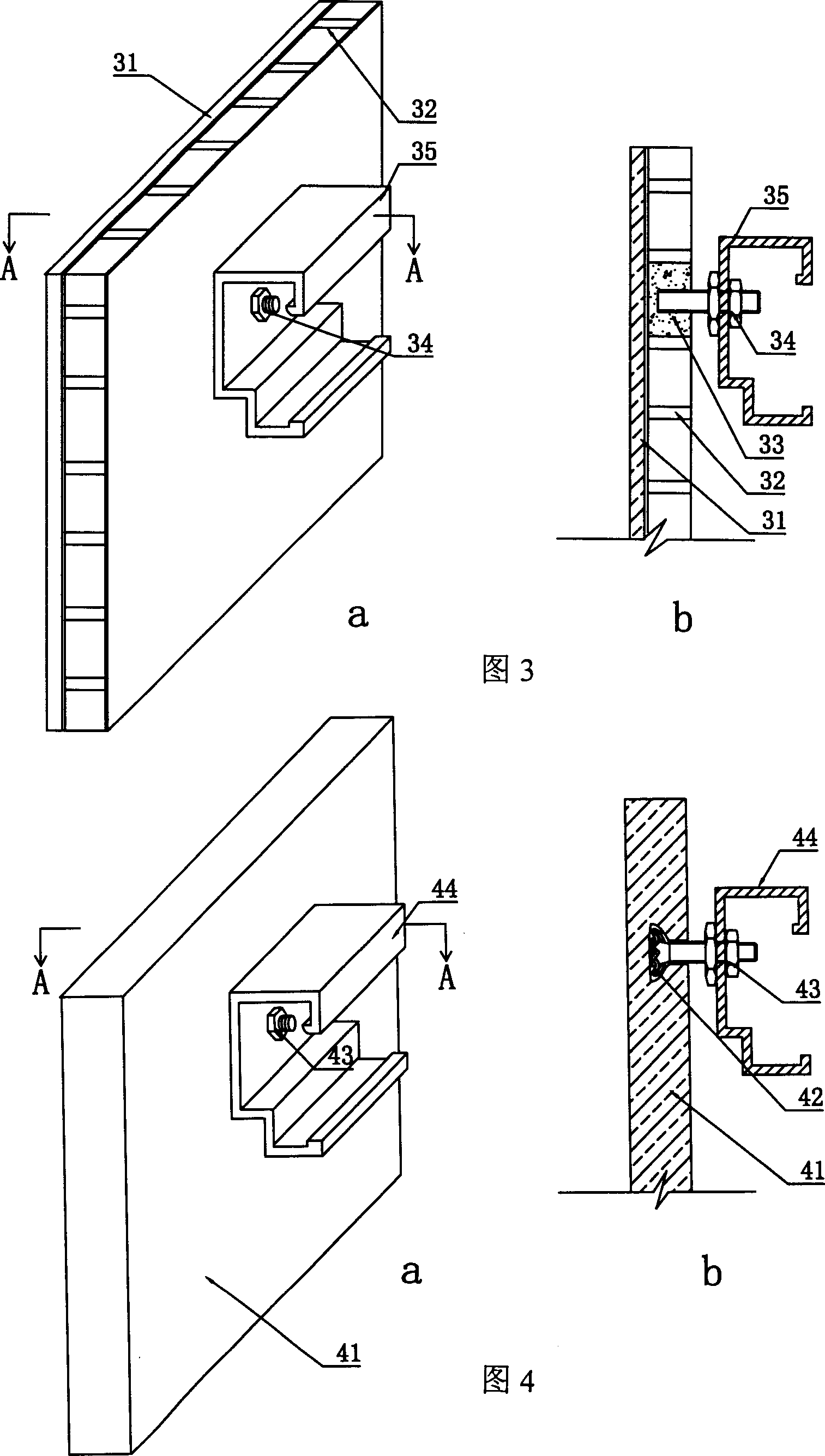

[0040] Embodiment 1 is an example of the combination of a single-layer stone veneer and a pre-embedded pendant. Its structure is as follows Figure 5As shown, wherein the stone facing layer 52 is natural granite, the length is 900mm, the width is 600mm, and the thickness is 20mm; the embedded pendant 51 is an aluminum alloy pendant with a T-shaped notch. The specific production method is as follows: firstly cut the stone veneer 52 into the specifications required by the project, then cut the pre-embedded pendant installation groove 53 in the stone veneer 52, after cleaning and drying the installation groove 53, paint in the groove. Epoxy resin glue is embedded into the pre-embedded hanger 51. The cross-section of the pre-embedded hanger is a geometric shape with a narrow slot end and a wide slot bottom end, and the two ends of the slot bottom are arc-shaped. This embodiment is suitable for stone curtain walls with relatively low height, low requirements on safety performance, ...

Embodiment 2

[0041] Embodiment 2 is an example of the combination of double-layer stone composite panels and embedded pendants, and its structure is as follows Figure 6 shown. Among them, the stone facing layer 62 is natural granite with a thickness of 15 mm; its back is compounded with a layer of reinforcement layer 63 with a thickness of 1 mm; the embedded pendant mounting groove 64 is cut on the back of the stone facing composite board; a T is embedded in the mounting groove. The aluminum alloy pre-embedded hanger 61 of type notch, the cross section of this pre-embedded hanger is the rectangular shape that a plug-in unit is connected at the groove bottom. The specific production method is as follows: first coat the back of the stone veneer 62 with epoxy resin glue, then spread the glass fiber cloth, make the epoxy resin glue penetrate into the glass fiber cloth thoroughly, bond it into a whole, dry and solidify, Form the reinforcement layer 63, and then cut it into engineering plates ...

Embodiment 3

[0042] Embodiment 3 is an example of combining a three-layer stone composite board with a pre-embedded pendant, and its structure is as follows Figure 7 As shown, wherein the stone facing layer 72 is natural granite with a thickness of 15mm; its back is compounded with a reinforced layer 73 with a thickness of 1mm; a layer of thermal insulation layer 74 is compounded at the back of the reinforced layer 73 with a thickness of 12mm; The back side of the composite board cuts the pre-embedded pendant installation groove 75; the engineering plastic pre-embedded pendant 71 with a T-shaped notch is embedded in the installation groove, and the cross section of the pre-embedded pendant is a stepped rectangular shape. Two plug-ins are attached to the bottom ends of the slot. The specific production method is as follows: first coat the two-component polyurethane glue on the back of the stone veneer 72, and then spread the glass fiber cloth, so that the two-component polyurethane glue th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com