Working technology for extracting ossein from animal cartilage

A processing technology and collagen technology, which is applied in the field of processing technology for extracting composite collagen, and can solve the problems of indigestion and absorption, waste and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

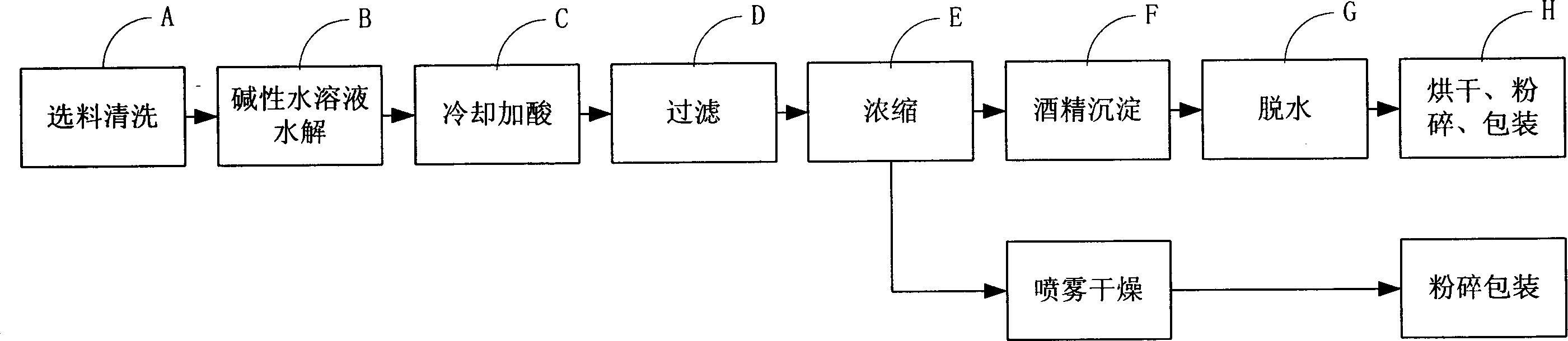

[0020] Example 1 takes the extraction of composite collagen from chicken breast cartilage as an example, but the present invention is not only applicable to taking chicken breast cartilage as a raw material. In fact, cartilage tissue of other animals can also be used as a raw material, but because chicken breast cartilage is relatively easy to obtain, it is preferred. Chicken breast cartilage. Please refer to figure 1 As shown, the present invention performs the following operation steps in sequence.

[0021] Step A: take healthy and hygienic chicken breast cartilage as a raw material, add water to the reaction tank until it is completely submerged, and soak for 4 hours; stir and clean the water for 20 minutes and let it go;

[0022] Step B: first add 10 times the amount of water, then add 30% aqueous sodium hydroxide solution to adjust the pH to 11, start stirring, and raise the temperature to 30°C to 35°C for hydrolysis for 4 hours;

[0023] Step C: After the hydrolysis is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com