Multi-point formation apparatus for sheet material

A plate, moldless and multi-point technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of unsatisfactory efficiency, processing quality and precision, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

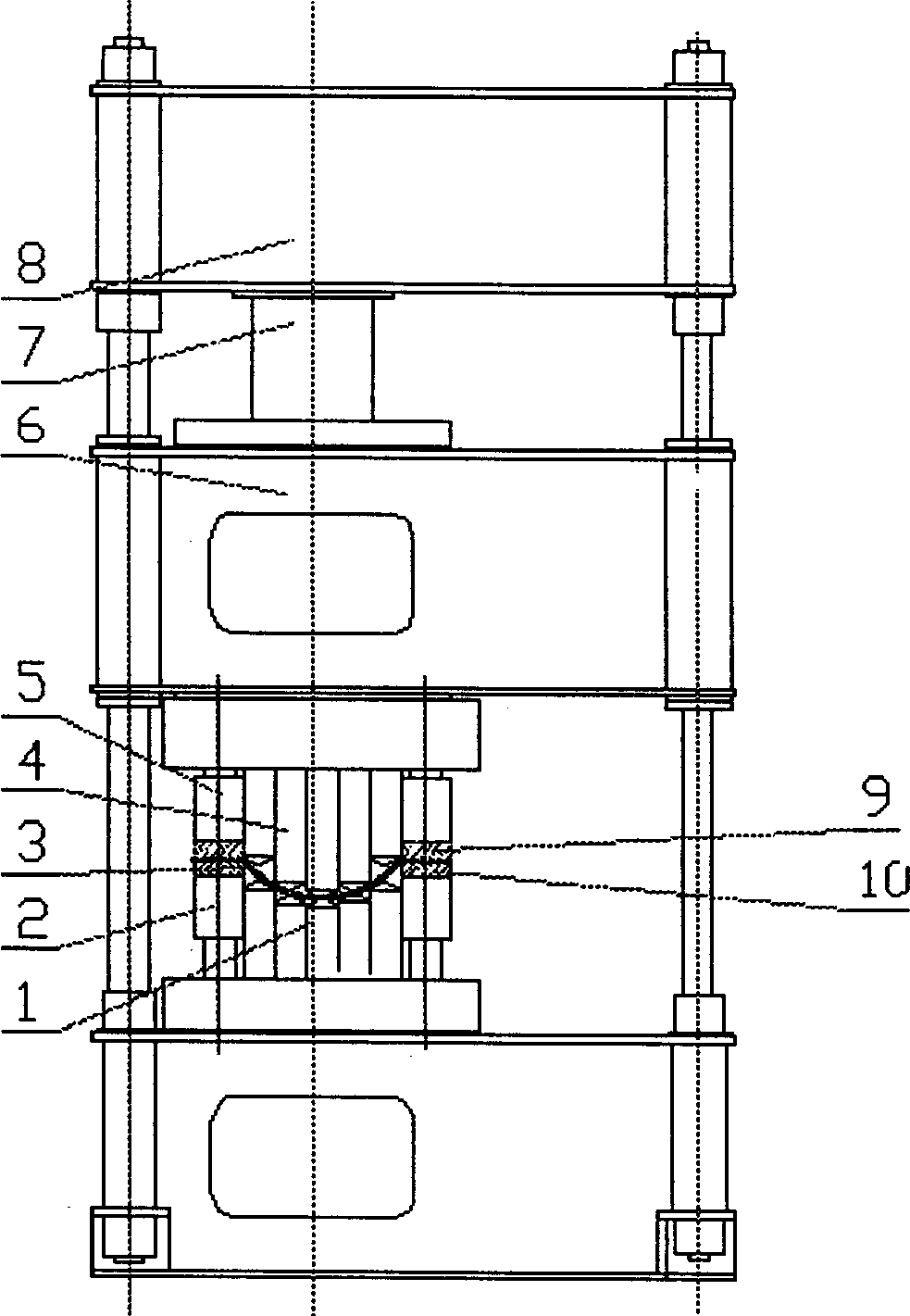

[0015] refer to figure 1 : Plateless multi-point forming device, which is composed of an upper and lower basic body control unit group consisting of a lower basic body control unit group 1 and an upper basic body control unit group 4, including a lower blank holder group 2 and an upper blank holder cylinder The upper and lower blankholders formed by the group 5, as well as the loading mechanisms 6, 7 and the upper and lower blankholders 9, 10. The plateless multi-point forming device is connected by the upper and lower beams through four columns, the movable beam 6 slides on the four columns between the upper and lower beams, and the four columns play a guiding role; the upper and lower basic groups and the basic body are arranged around the The blank holders are respectively fixed on two large plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com