Prepn of particle-reinforced composite material

A composite material and particle-reinforced technology, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of immature technology and many inclusions on the surface, and achieve uniform distribution of reinforced particles, pure surface and good fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

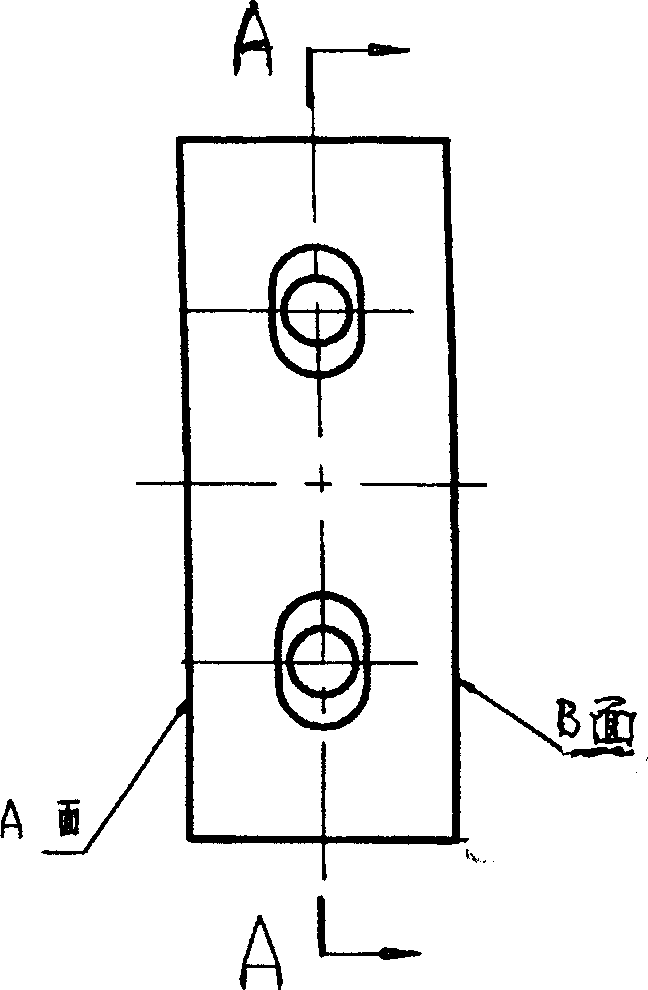

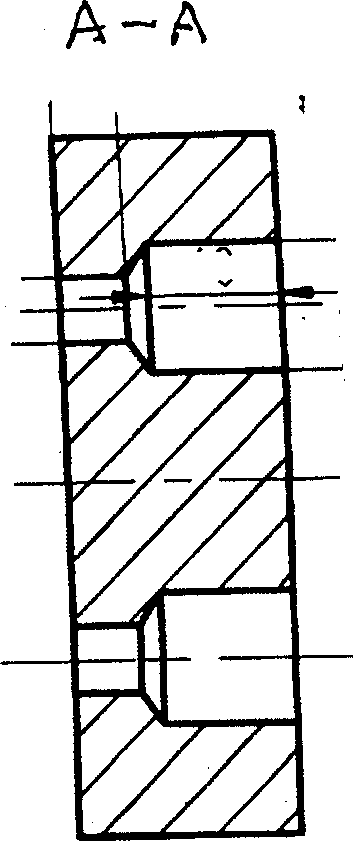

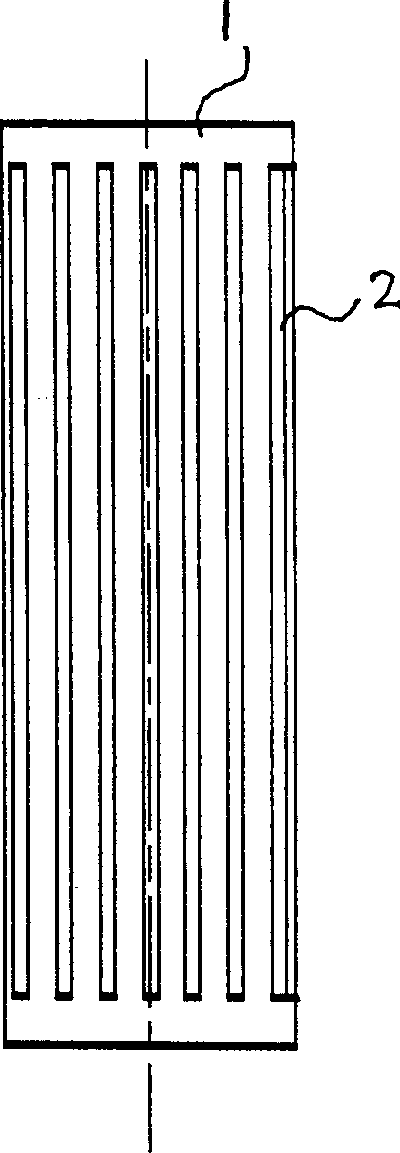

[0022] Example 1, figure 1 , figure 2 It is a simplified structural diagram of the blow bar. Both sides A and B are used surfaces, which require high wear resistance. They are made of WC and high-chromium cast iron composite wear-resistant materials. The particle size of WC is 50-100 mesh, and the grade of high-chromium cast iron is KmTBCr15. This embodiment is the preparation method of the above-mentioned composite wear-resistant material, with reference to image 3 , Figure 4 :according to image 3 The foam plastic mold 1 is prepared as shown, and the groove 2 on the body is filled with dry and clean WC reinforcing particles into the groove of the foam plastic mold; after the foam plastic mold is bonded, paint, dry, shape, and vacuumize; The molten iron of high chromium cast iron with qualified composition is poured into the mold. The pouring temperature is 1400°C, and after cooling, the box is opened to obtain composite wear-resistant material castings with WC particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com