Cyclonic mass-transferring reaction and product separation method and separator

A separation method and mass reaction technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of many process units, high waste water cost, and need to be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

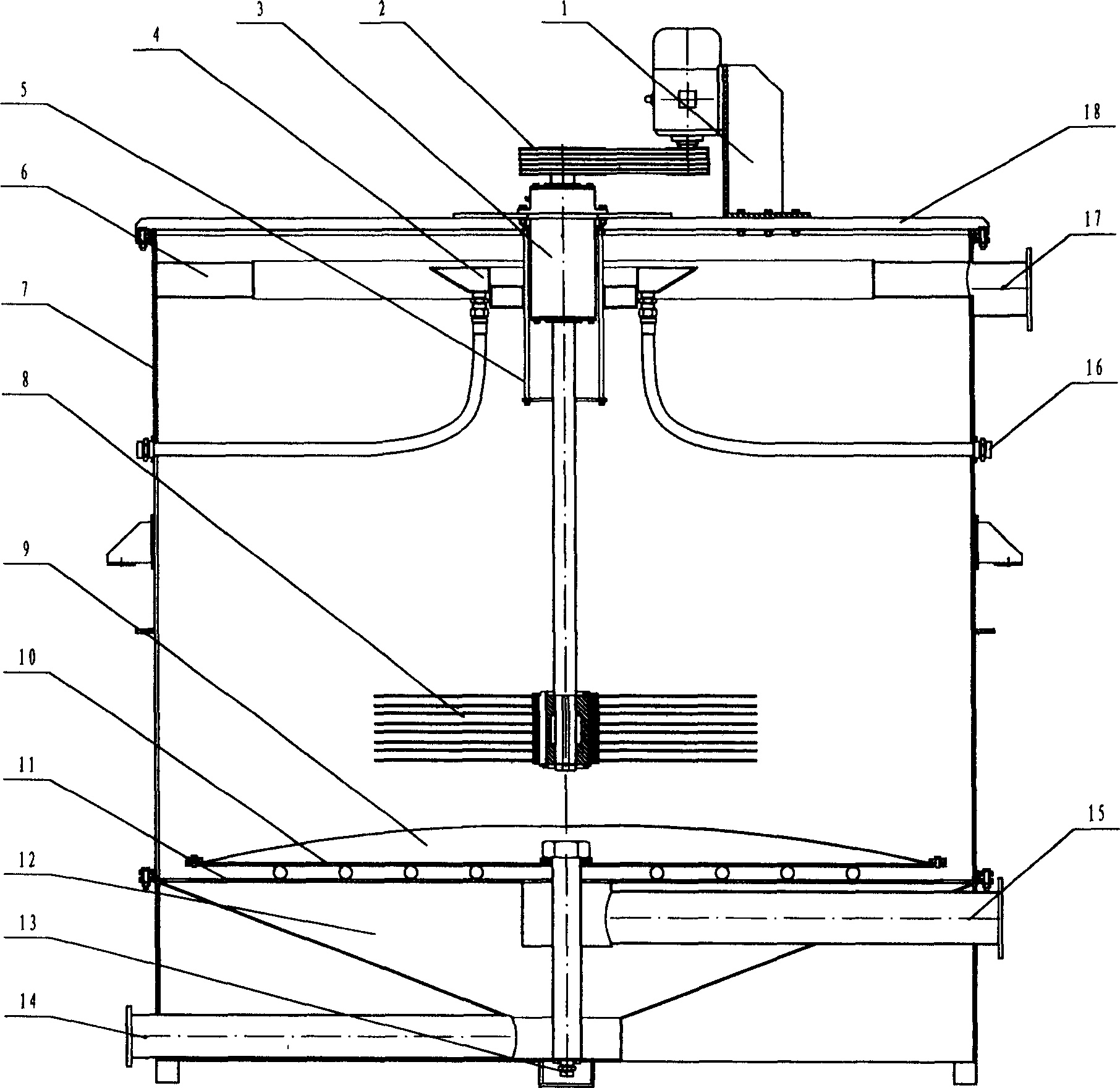

[0140] see figure 1 , which is an integral aeration gas flotation gas-liquid mass transfer chemical reaction tank designed according to the technical scheme of the present invention, used for mass transfer and product separation of aeration, air flotation, stripping, stripping, and for Chemical reactions such as neutralization, oxidation, reduction, acid-base salt precipitation and product separation, used for crystallization and crystal separation.

[0141] The reaction tank includes an upright swirl chamber 7, a transmission device 3, a pin wheel 8, a slurry mixer 10, an aeration device 9, and a flotation material skimming device.

[0142] Transmission device 3 is made up of motor, bearing box, power transmission shaft, belt pulley 2 etc. The stirrer rotor is coaxial with the swirl chamber 7. The transmission device 3 is located at the top of the swirl chamber 7, the transmission shaft extends below the middle position in the chamber, and the agitator is fixed on the trans...

Embodiment 2

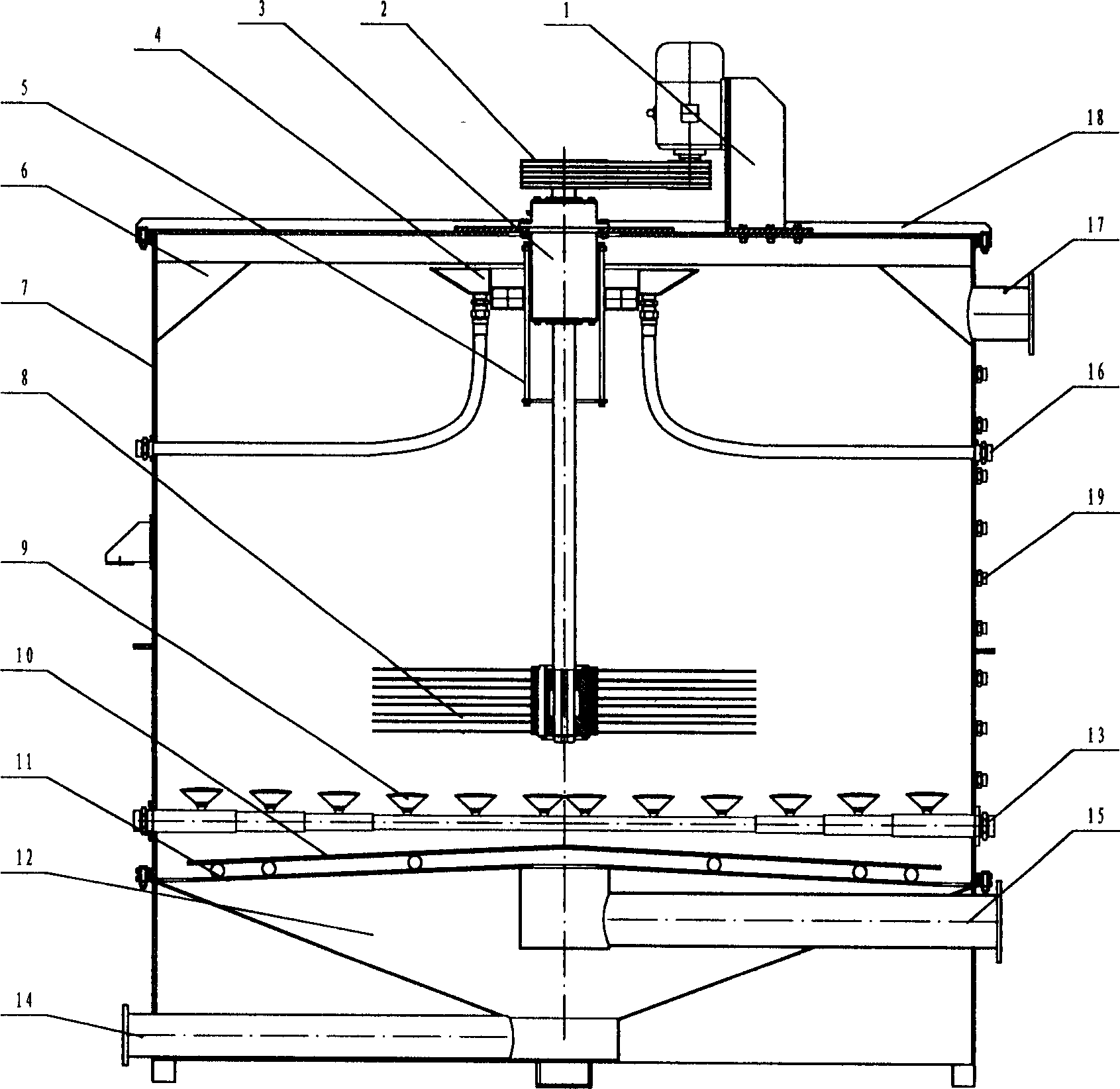

[0150] see figure 2 , which is a multi-head aeration air flotation gas-liquid mass transfer chemical reaction tank designed according to the technical scheme of the present invention, used for aeration, air flotation, stripping, stripping and product separation for mass transfer and product separation. Chemical reactions such as neutralization, oxidation, reduction, acid-base salt precipitation and product separation, used for crystallization and crystal separation.

[0151] The reaction tank includes an upright swirl chamber 7, a transmission device 3, a pin wheel 8, a slurry mixer 10, an aeration device 9, and a flotation material skimming device. The difference from Example 1 is:

[0152] The aeration device 9 adopts the form of multiple aeration scattered arrangements, and the air inlet 13 is on the side wall of the housing;

[0153] A number of overflow ports 19 are left on the shell, and the upper opening of the swirl chamber is covered and connected by flanges;

[0...

Embodiment 3

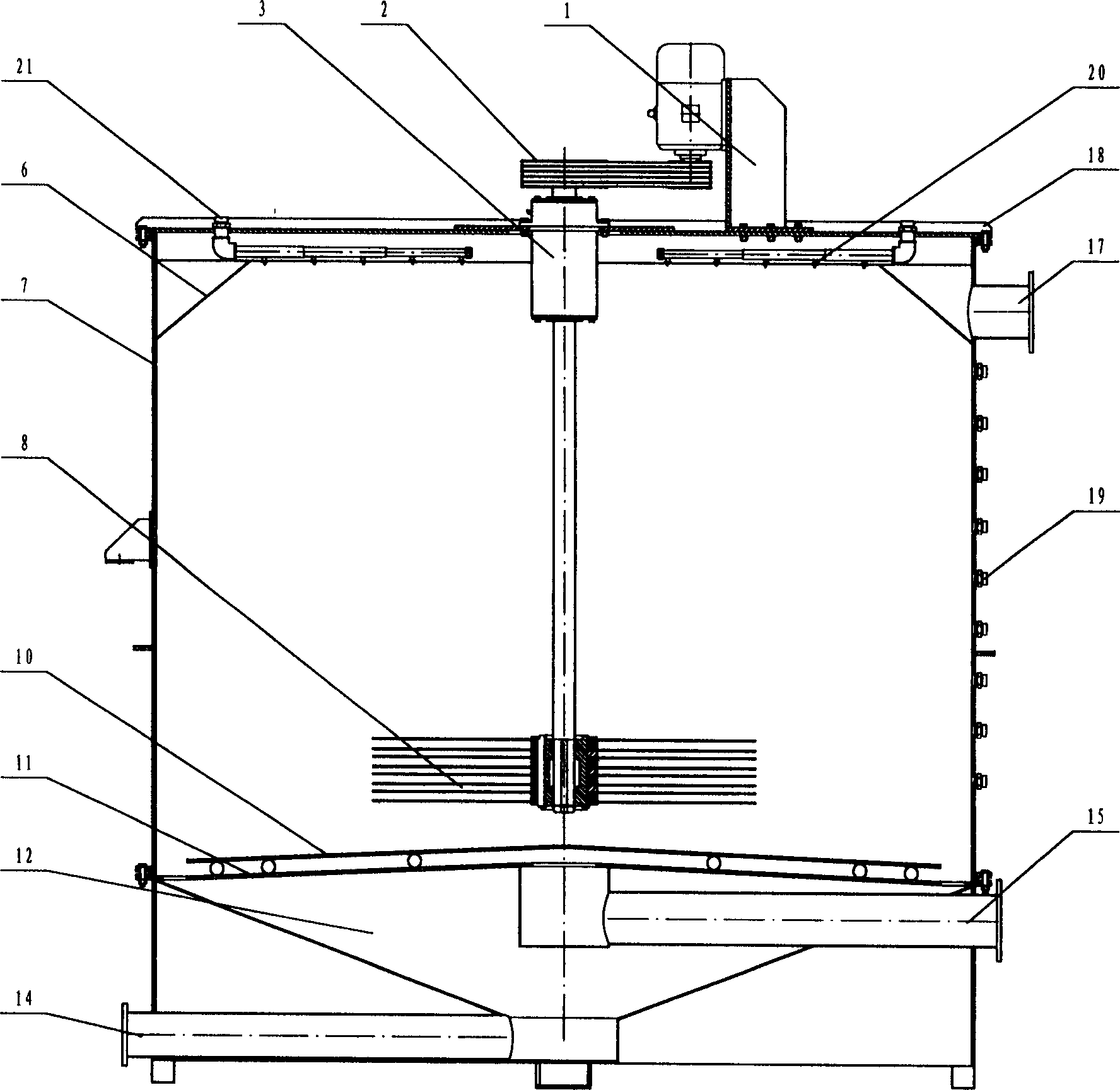

[0157] see image 3 , which is a swirling liquid-liquid mass transfer chemical reaction tank designed according to the technical scheme of the present invention, used for coagulation, extraction, mass transfer and product separation, used for neutralization, oxidation, reduction, acid-base Salt precipitation is a kind of chemical reaction and product separation, which is used for crystallization and crystal separation.

[0158] The reaction tank includes an upright swirl chamber 7, a transmission device 3, a pin wheel 8, a slurry dispenser 10, and a liquid spraying device. The difference with embodiment two is:

[0159] There is no aeration device 9, no flotation material skimming device, and no pedestal 5;

[0160] The liquid spraying device is composed of a plurality of atomizing nozzles 20, radially distributed liquid spraying pipes, and joints. The dosing port 21 is fixed on the cover plate;

[0161] The sizing port 17 of the swirl bin is a sizing port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com