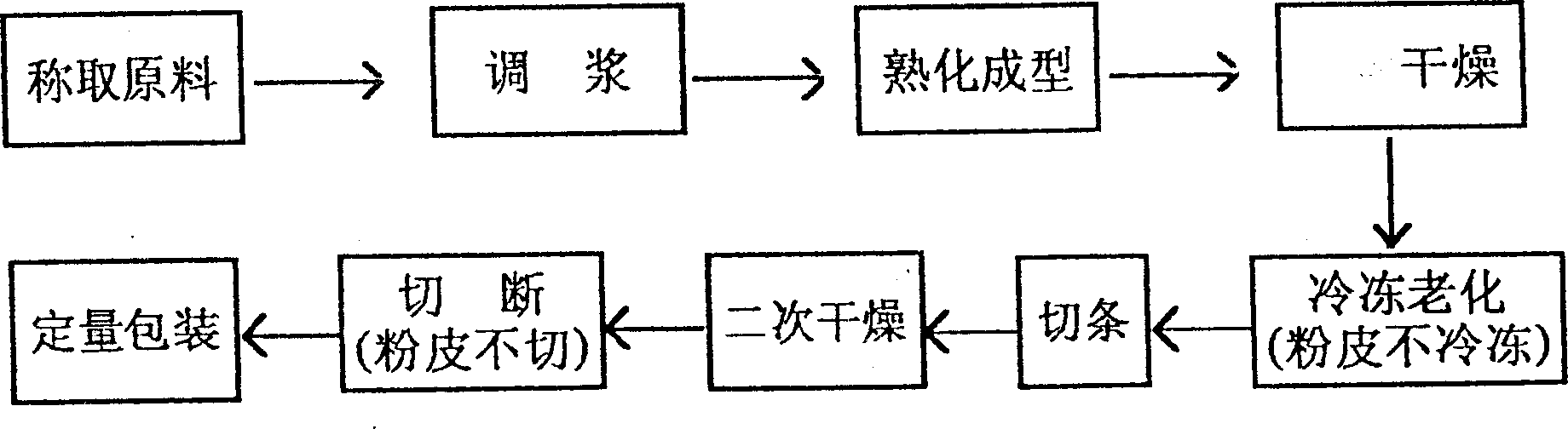

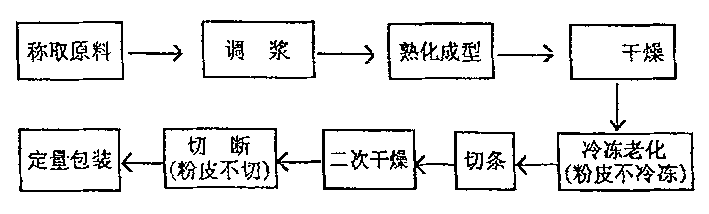

Production process of noodles and sheet jelly made from arrowroot starch

A processing method and technology of vermicelli, applied in the fields of application, food preparation, food science, etc., can solve problems such as gluten strength, insufficient toughness, intolerance to cooking, unsuitable eating habits, etc., to achieve a flat and smooth surface, not easy to paste the soup and break the strips, White and transparent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one (general plan)

[0030] Weigh raw materials: get 10 parts (such as kilograms, the same below) Pueraria starch (adopting the high-quality Pueraria starch produced by the company's Taoyuan Starch Factory, the same below), 90 parts of refined corn starch;

[0031] Mixing: Take 1 part of kudzu starch, mix it with 1 part of cold water, and then use 15 parts (15 times) of boiling water (the prepared slurry, the same below) to make a transparent paste, stir it evenly, and pour in the raw materials after cooling (starch, the same below), stir while adding water, until the water content of the whole raw material slurry is 55%;

[0032] Aging and forming: Pour the stirred slurry into the hopper, spread the film evenly on the transmission stainless steel belt, enter the steam box to steam the slices, the temperature of the steaming slices is 120°C, and the time is 2.5 minutes;

[0033] Cooling and drying: transfer the powder flakes from the stainless steel belt to ...

Embodiment 2

[0038] Embodiment two (preferred scheme)

[0039] Weighing raw materials: take 20 parts of kudzu root starch, 80 parts of refined tapioca starch; mixing: take 2 parts of tapioca starch, mix evenly with 2 parts of cold water, then use 50 parts (25 times) of boiling water to make a transparent paste, stir evenly immediately, Pour it into the raw material after cooling, and stir while adding water until the water content of the whole raw material slurry is 60%; other process steps such as ripening and molding, cooling and drying, freeze aging, cutting into strips, secondary drying, cutting, and packaging are the same as in Example 1. However, the steaming temperature is 130°C and the time is 3.5 minutes; cooling and drying to a water content of 50%; freezing temperature is 0°C and a time of 70 minutes; secondary drying to a water content of 15%.

Embodiment 3

[0040] Embodiment three (best solution)

[0041] Weigh raw materials: take 20 parts of kudzu root starch and 80 parts of refined potato starch, mix them evenly, take out 1.5 parts of them and mix them with 1.5 parts of water, then use 30 parts (20 times) of boiling water to make a transparent paste, stir evenly at once, after cooling Pour into the raw material, stir while adding water, until the water content of the whole raw material slurry is 62%; The sheet temperature is 125°C for 3 minutes; cooling and drying to a moisture content of 45%; freezing temperature at -1°C for 1 hour; secondary drying to a moisture content of 14%.

[0042] Arrowroot skin processing:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com