Frequency output type micromechanical dual-beam resonator with autoamtic temp compensation

A double-beam resonator and frequency output technology, applied in the field of micro-electronic mechanical systems, can solve problems such as long response time, large distance between temperature measuring elements and measuring sensors, and difficulty in reflecting the real temperature of the measuring point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

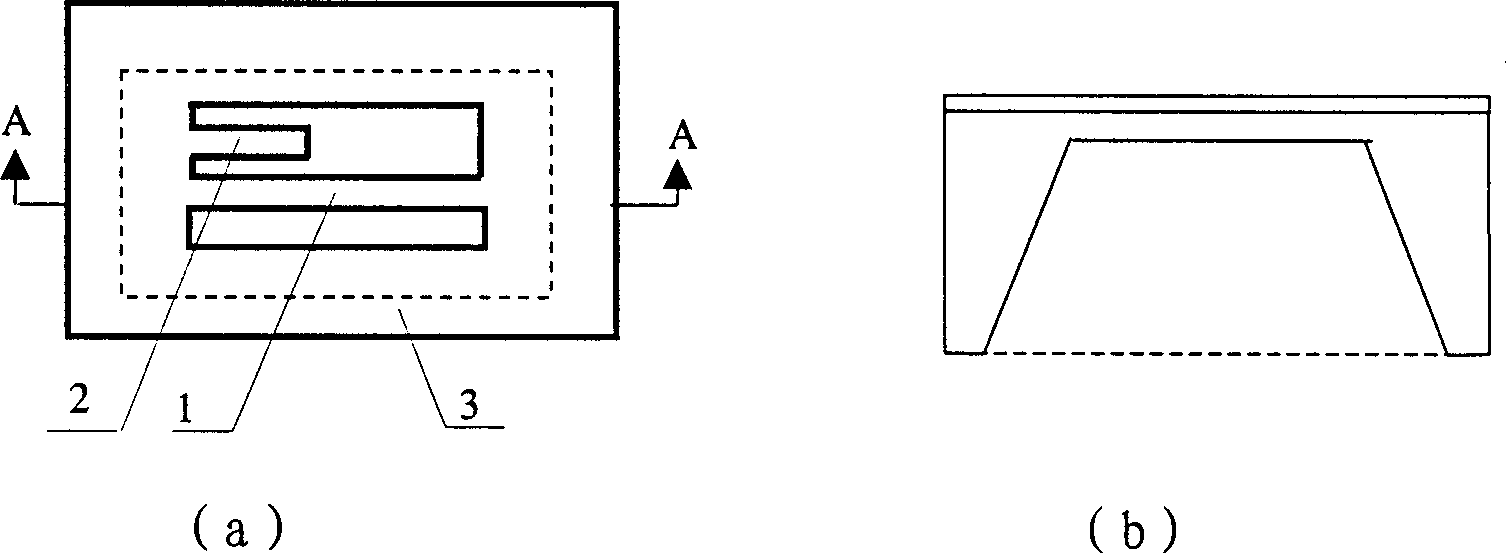

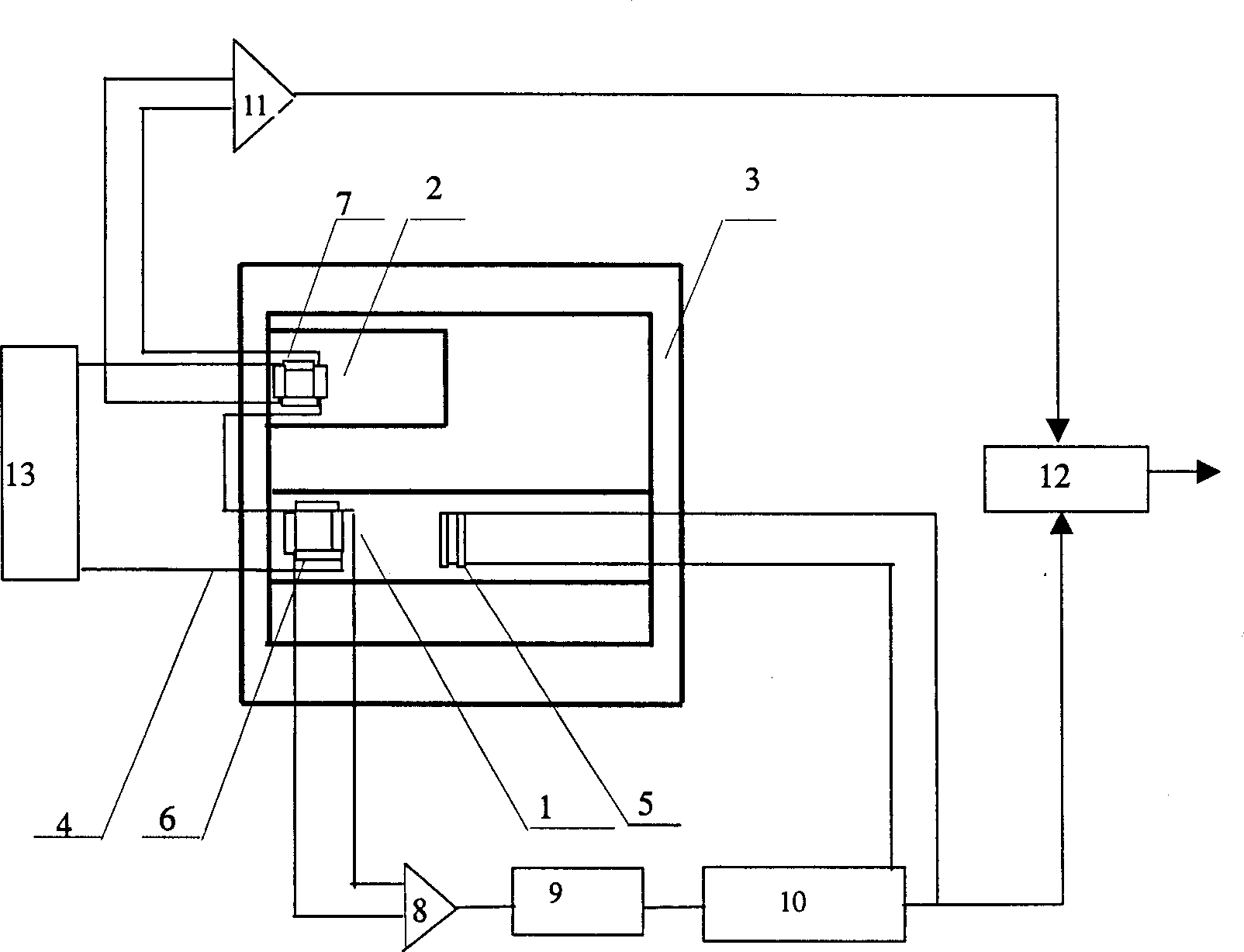

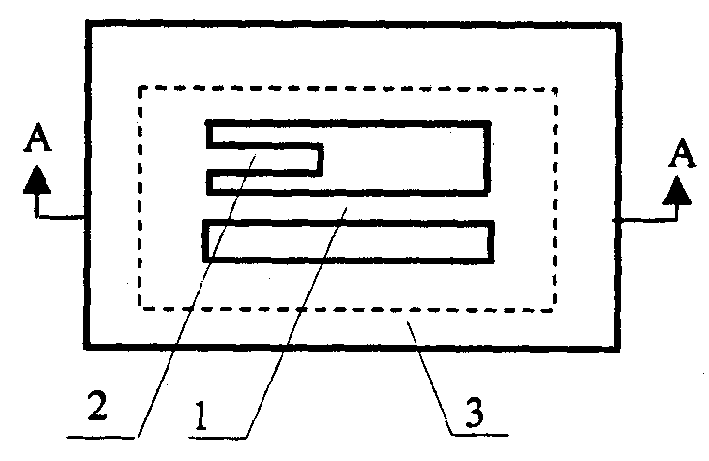

[0012] Example: see figure 1 , 2, including micro-bridge resonator 1, micro-cantilever temperature-sensitive element 2 and substrate 3, leads 4, amplifiers 8, 11, band-pass filter 9, phase shifter 10, data fusion unit 12 and constant voltage source 13.

[0013] The micro-bridge resonator 1 adopts the working mode of electrothermal excitation / varistor picking up vibration. The middle part of the micro-bridge resonator 1 is made with an excitation resistor 5 to excite the device to vibrate, and the fixed end is made with a piezo-sensitive bridge 6 to pick up the vibration signal; a diagonal of the piezo-sensitive bridge 6 at the root of the micro-bridge resonator 1 passes through The lead 4 is connected to the two input terminals of the differential amplifier 8, the output terminal of the differential amplifier 8 is connected to the input terminal of the band-pass filter 9 through the lead 4, and the output terminal of the band-pass filter 9 is connected to the phase shifter thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com