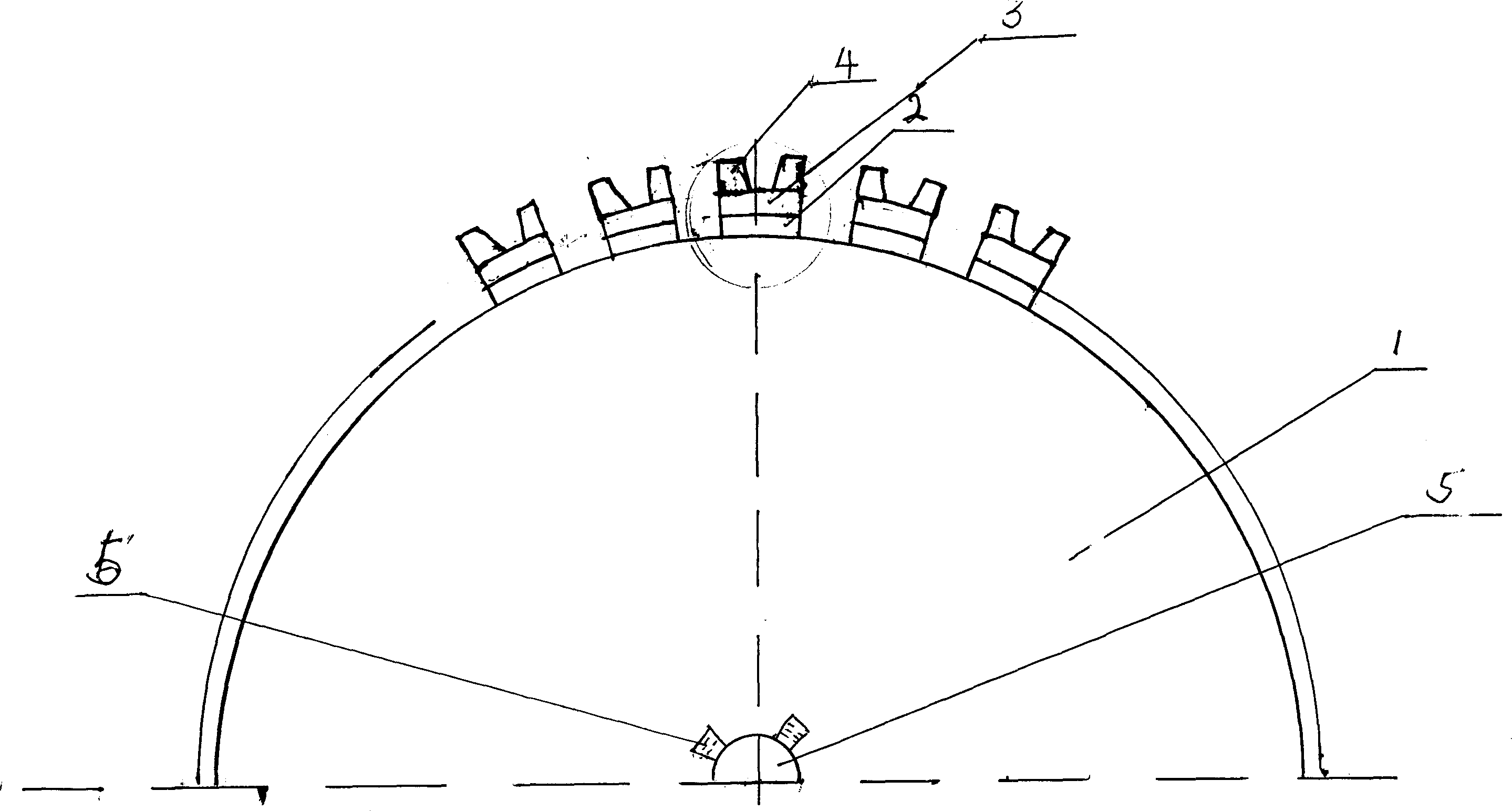

Composite saw blade

A technology of compound saws and saw blades, which is applied in the direction of metal sawing equipment, cutting tools of sawing machine devices, metal processing equipment, etc., can solve the problems of undiscovered; only etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

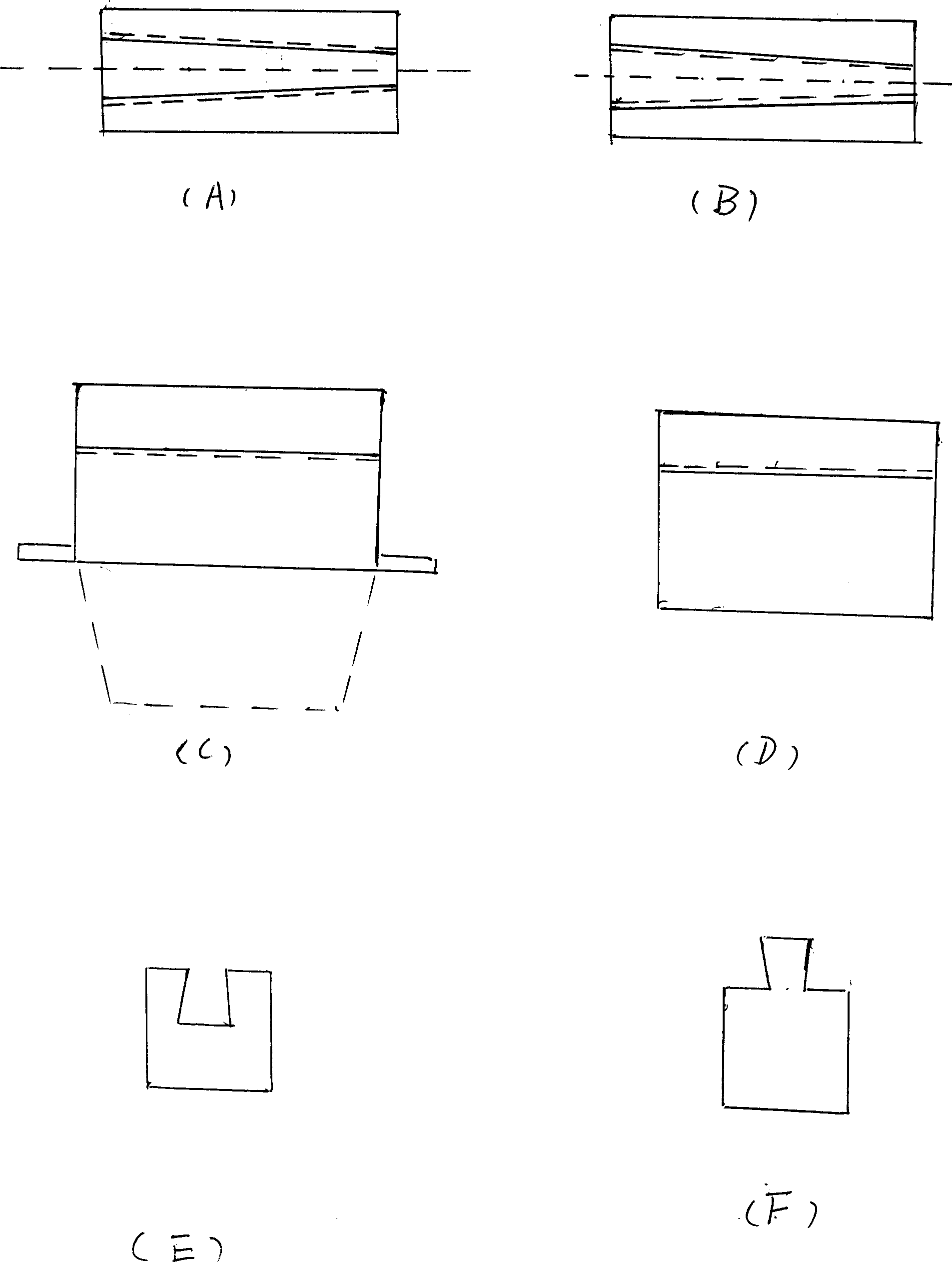

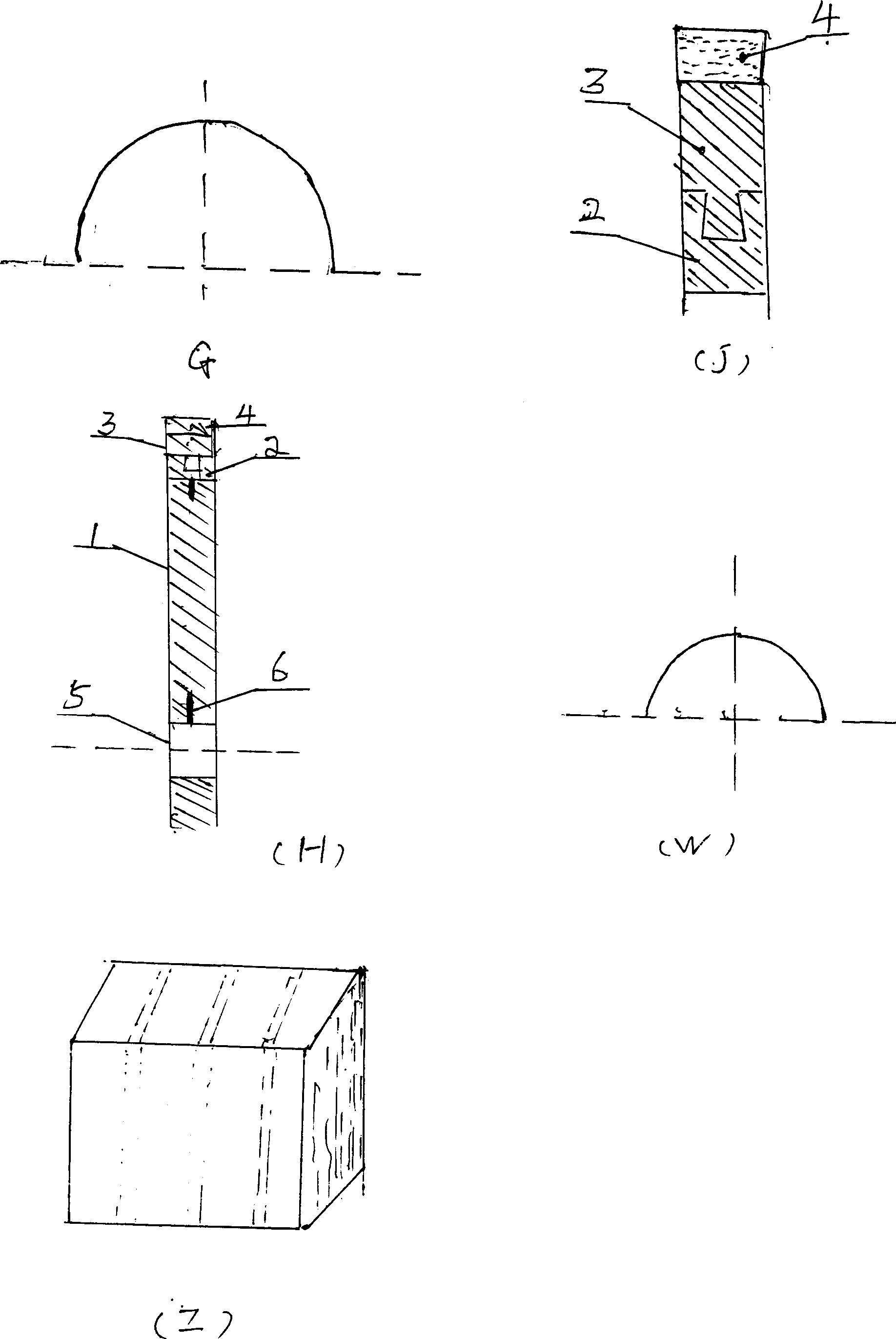

Method used

Image

Examples

Embodiment Construction

[0023] In the first embodiment, by total weight: glass fiber cloth is 20-35wt%, carbon fiber is 2-10wt%, epoxy resin is 30-60wt%, others are conventional curing agent, filler, diluent, infiltration agent etc. The specific steps are as follows: Cut the carbon fiber and glass fiber cloth into shape according to the required size, prepare several, first put one into the mold that is cleaned and coated with a release agent, and the wetting agent used for the mold is alkali such as hydrogen Sodium oxide, sodium carbonate, potassium hydroxide, etc. Then put the embedded parts (metal parts such as knife seat or lower knife seat and center positioning ring (shaft sleeve)) at the predetermined position; stir and mix epoxy resin, quartz sand and other fillers in another container. Conventional accelerator diluent ( Such as propylene oxide), etc., mix part of the mixture with curing agent such as amines of m-phenylenediamine and pour it into the mold to level it. Repeat the operations ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com