Nano carbon tube reinforced plastics/ceramics-base composition for repairing bone

A composite material and carbon nanotube technology, used in medical science, prostheses, etc., can solve the problems of inability to promote bone cell growth, no osteoconductivity, non-bacterial inflammatory response, etc., and achieve good biodegradability, The effect of good biocompatibility and sufficient mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

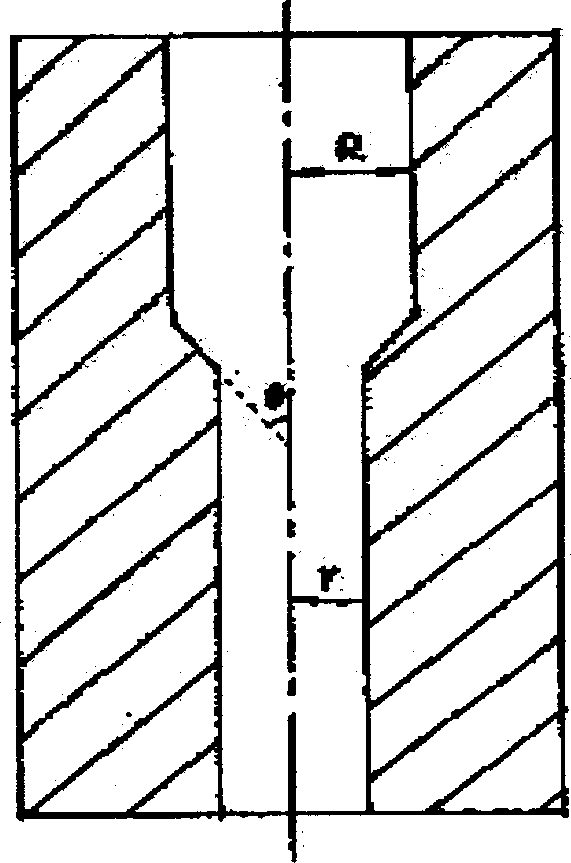

[0026] Fill the fully ground and mixed PHB powder (87wt%), HA powder (10wt%) and carbon nanotubes (3wt%) figure 1 In the cavity of the upper mold shown, and preset large-grained PHB raw materials in the cavity of the upper mold to prevent the powder from falling. at 3×10 7 It was extruded into the cavity of the lower die under a pressure of 120 Pascals, the mold was cooled to room temperature and the extruded sliver was taken out.

Embodiment 2

[0028] Fill the fully ground and mixed PHB powder (75wt%), TCP powder (20wt%) and carbon nanotubes (5wt%) figure 1 In the cavity of the upper mold shown, and preset large-grained PHB raw materials in the cavity of the upper mold to prevent the powder from falling. in 8×10 7 It was extruded into the cavity of the lower die at 110° C. under Pascal pressure, the die was cooled to room temperature and the extruded sliver was taken out.

Embodiment 3

[0030] Fill the fully ground mixed PHB powder (59.85wt%), HA powder (30wt%) carbon nanotubes (10wt%) and nucleating agent ammonium chloride (0.15wt%) figure 1 In the cavity of the upper mold shown, and preset large-grained PHB raw materials in the cavity of the upper mold to prevent the powder from falling. at 3×10 8 It was extruded into the cavity of the lower die at 100° C. under Pascal pressure, the die was cooled to room temperature and the extruded sliver was taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com