Stuffing-throwing fluidized bed membrane bioreactor and water treating method

A bioreactor, fluidized bed technology, applied in the field of water and wastewater treatment, can solve the problem of low microbial degradation efficiency, and achieve the effects of reducing the amount of suspended sludge, resisting shock loads, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

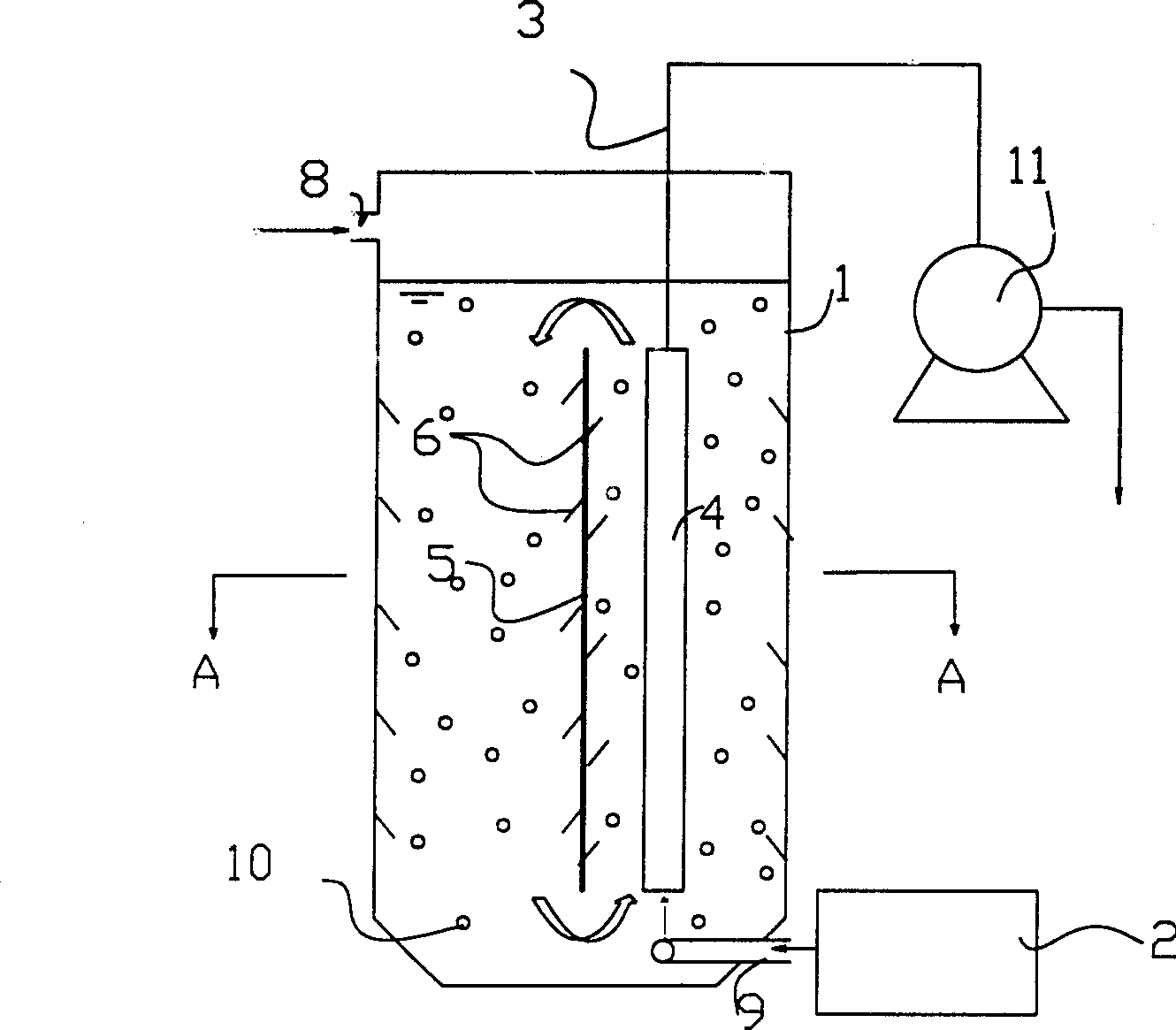

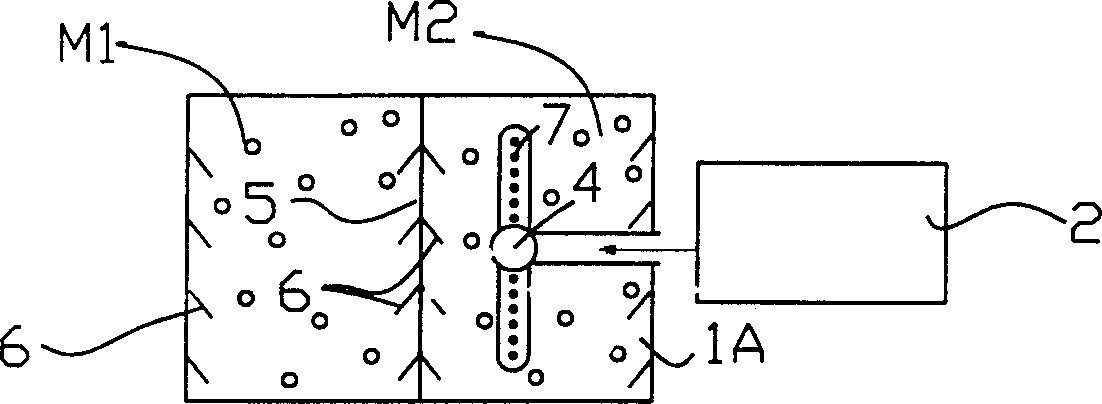

[0025] figure 1 Represent the fluidized bed type membrane-bioreactor device of embodiment one, this device is by cuboid reactor shell 1, air supply device 2, adopts perforated pipe air distribution device 7, outlet pipe 3, membrane module 4, deflector 5. The cyclone device 6 is composed, and a suction pump 11 is arranged on the outlet pipe of the reactor. The reactor shell 1 is a hollow cuboid structure, its axis is perpendicular to the horizontal plane, and its upper side is provided with a water inlet pipe 8,

[0026] The gas inlet 9 of the air supply device 2 is directly below the membrane module. The membrane module can be a curtain-shaped hollow fiber membrane module, a bundle-shaped hollow fiber membrane module, a flat-plate membrane module or a tubular membrane module. The deflector 6 arranged in the middle of the device divides the interior of the device into left and right regions, which are respectively the upflow region M2 and the downflow region M1. The water ou...

Embodiment 2

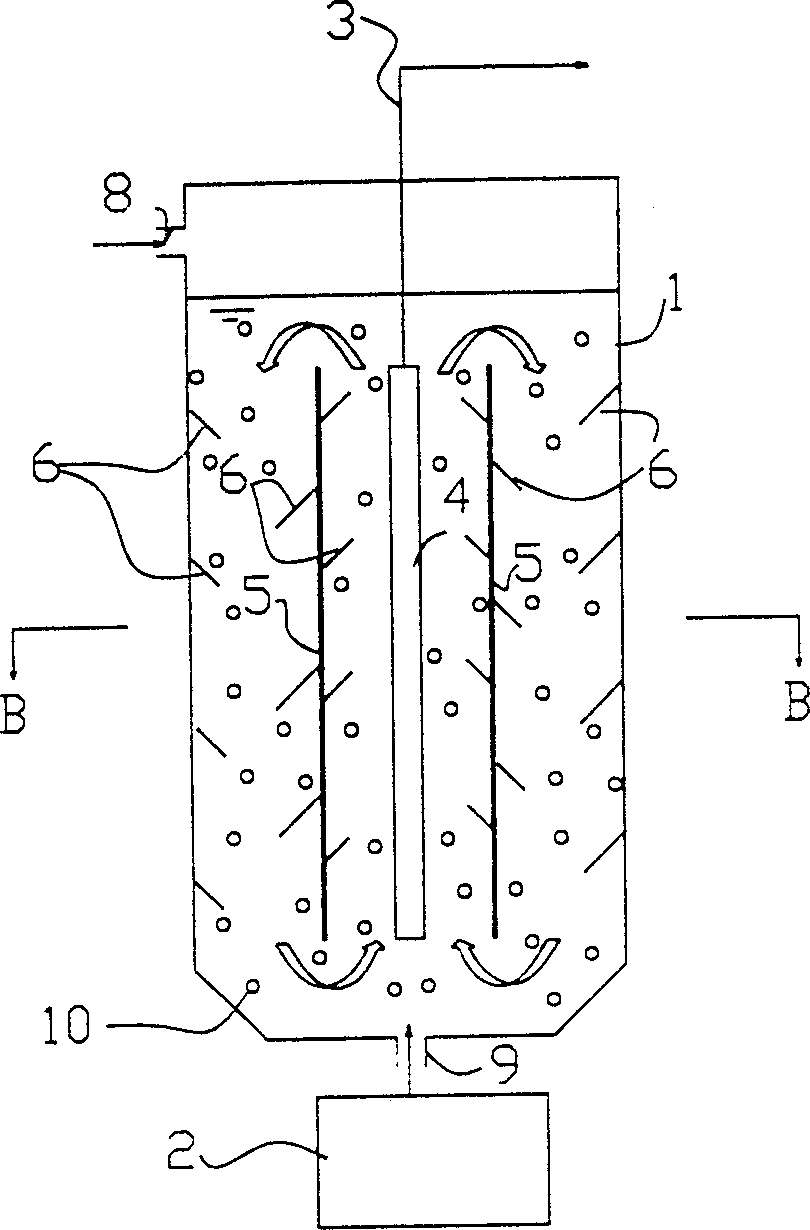

[0029] image 3It is the fluidized bed type membrane-bioreactor device of embodiment 2 with filler added. The device consists of a cylindrical reactor shell 1, an air supply device 2, a perforated pipe air distribution device 7, a water outlet pipe 3, a membrane module 4, a guide tube 5 and a swirl plate 6. In the figure, the upper side of the reactor is provided with a water inlet pipe 8, and the center of the bottom is provided with a gas inlet 9 from an air supply device, and the 9 is directly below the membrane module. The membrane modules can be bundled hollow fiber membrane modules or tubular membrane modules. The guide cylinder provided in the middle of the device divides the interior of the device into two areas, the central area Q1 and the peripheral area Q2. The water outlet pipe 3 is connected with the collection port of the membrane module 4, and the collection port of the membrane module can be arranged at the upper part or the lower part of the membrane module....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com