Induction synchro motor

A technology of synchronous motors and electric angles, which is applied to asynchronous induction motors, synchronous machines, synchronous motors with stationary armatures and rotating magnets, etc., can solve the problems of cost increase and achieve the effect of large reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

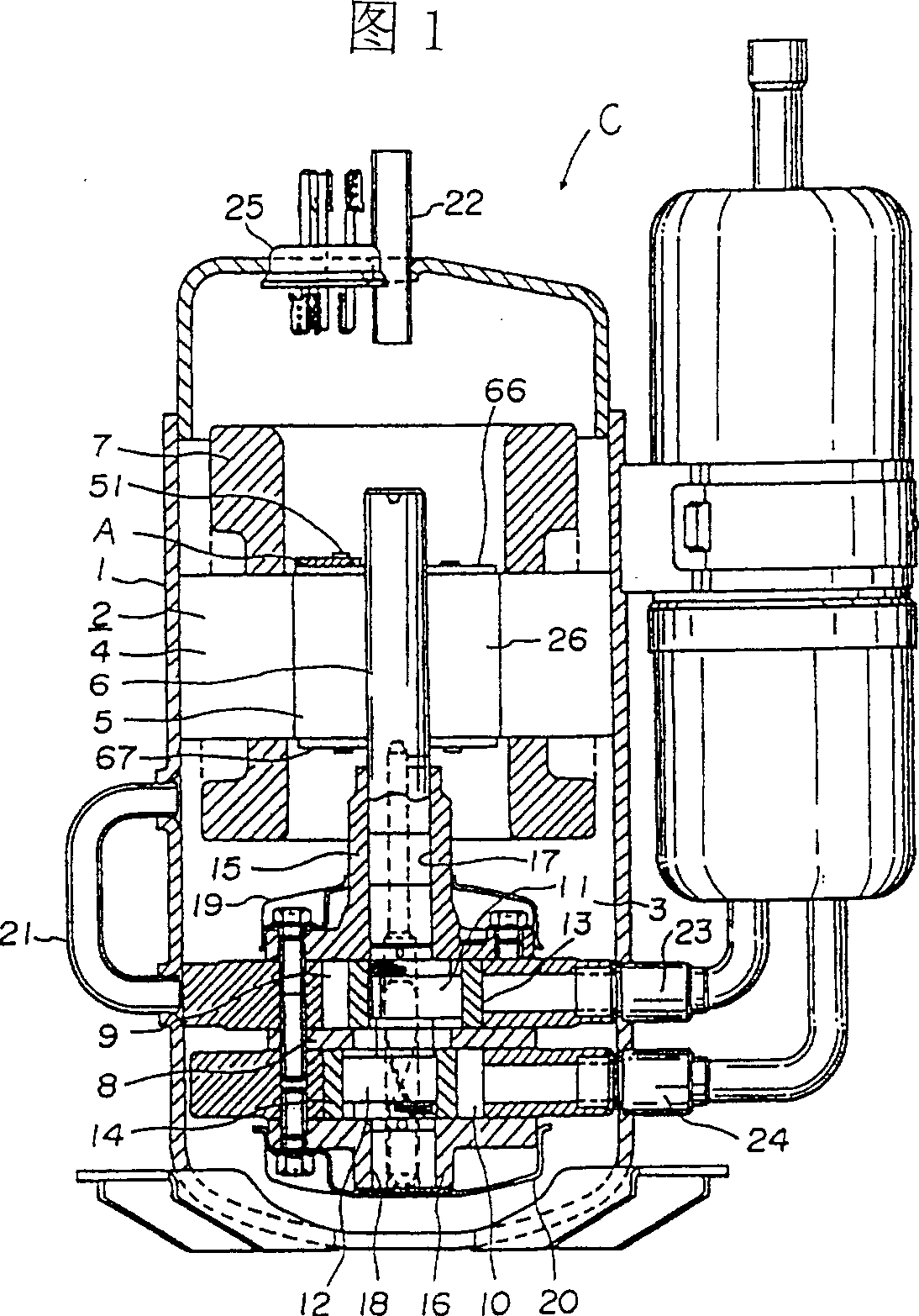

[0027] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Fig. 1 is a vertically sectional side view of a hermetic electric compressor C using an induction synchronous motor 2 according to the present invention. In this figure, reference numeral 1 is an airtight container, and an induction synchronous motor 2 is accommodated on the upper side thereof, and a compressor 3 driven to rotate by the induction synchronous motor 2 is accommodated on the lower side. The airtight container 1 is divided in advance, the induction synchronous motor 2 and the compressor 3 are housed therein, and then closed by high-frequency welding or the like. Examples of the hermetic electric compressor C include rotary compressors, reciprocating compressors, and scroll compressors.

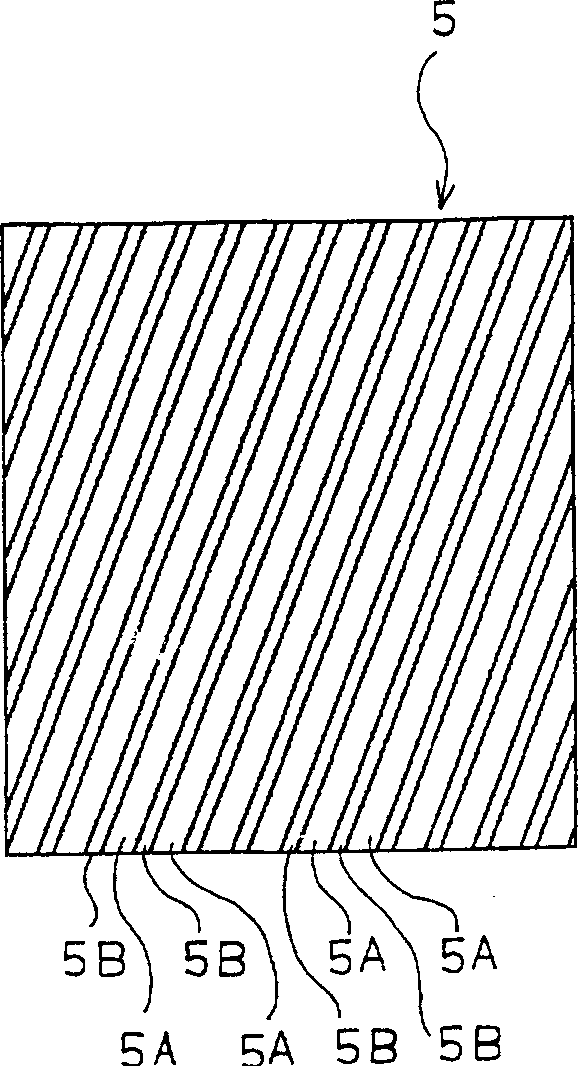

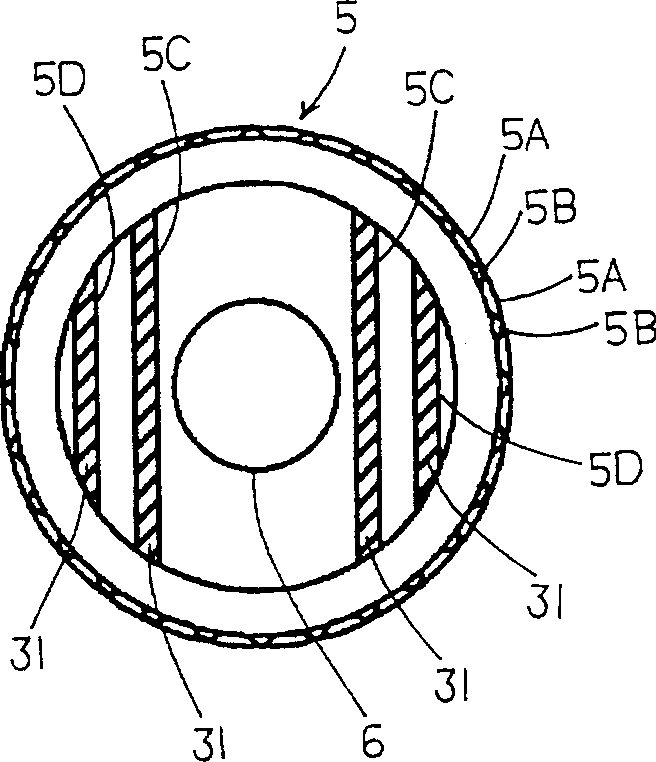

[0028] The induction synchronous motor 2 is composed of a stator 4 and a rotor 5. The stator 4 is composed of single-phase two poles and is fixed on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com