Low-pressure mercury-vapor discharge lamp and amalgam

A technology of mercury vapor and discharge lamps, which is applied in the direction of low-pressure discharge lamps and parts of gas discharge lamps, and can solve the problems of radiation output reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

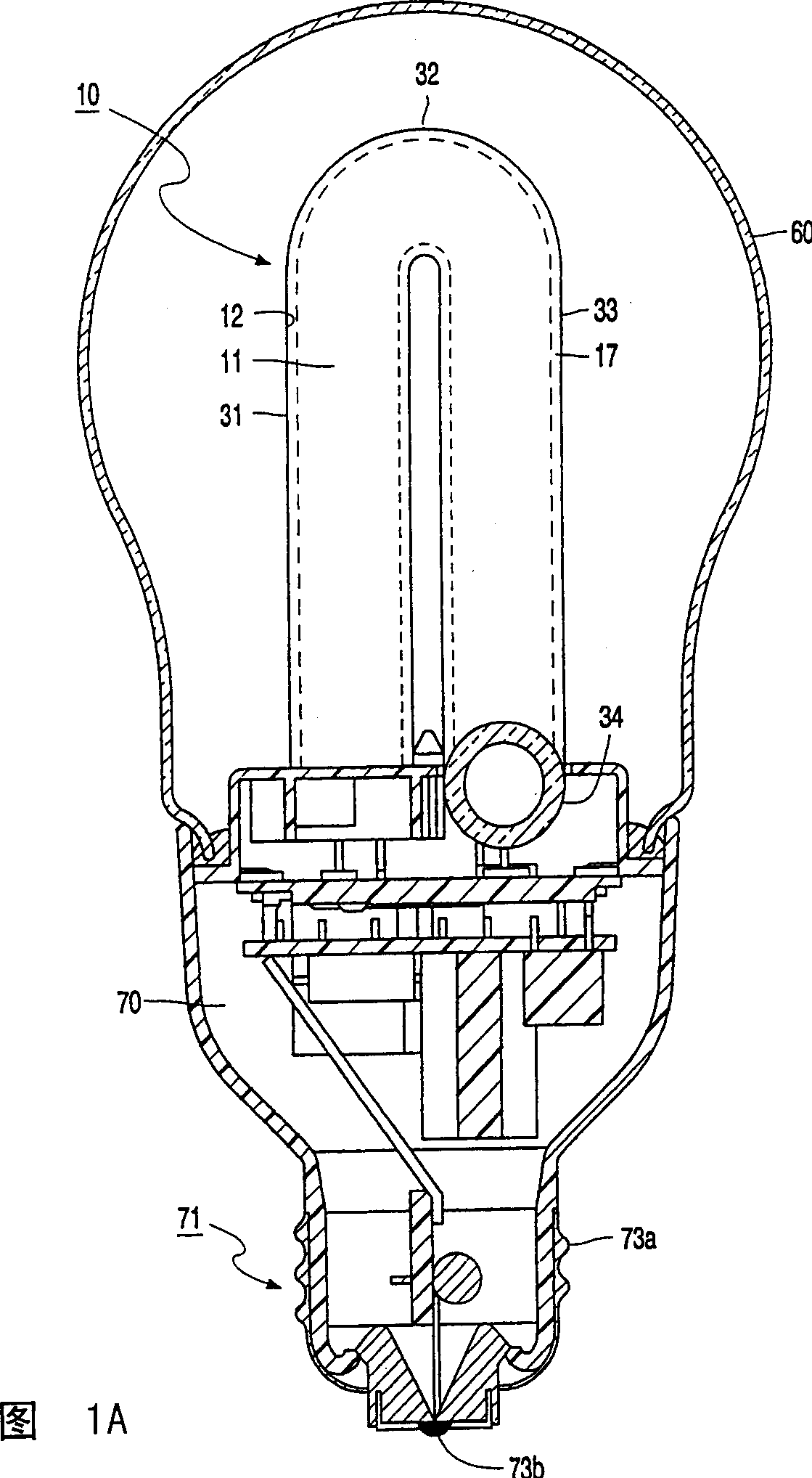

[0032]Figure 1A shows a compact fluorescent lamp comprising a low pressure mercury vapor discharge lamp. The low-pressure mercury vapor discharge lamp is provided with a radiation-transmissive discharge vessel 10 which is closed in a gas-tight manner with a diameter of about 10 cm. 3 The volume of the discharge space 11 . The discharge vessel 10 is a glass tube with an at least substantially circular cross-section and an (effective) inner diameter of about 10 mm. The glass tube is bent into a so-called hook shape and, in this example, comprises a number of straight tube sections, two straight tube sections 31 , 33 are shown in FIG. 1A . The glass tube also includes a number of arcs, two arcs 32, 34 are shown in Figure 1A. The discharge vessel 10 is provided with a luminescent layer 17 on the inner wall 12 . In another embodiment, the light emitting layer is omitted. The discharge vessel 10 is supported by a housing 70 which also supports a lamp cap 71 provided with electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com