Rolling bearing and bearing unit

A technology for rolling bearings and bearings, applied in the direction of bearings, ball bearings, bearing components, etc., can solve the problems of bearing life damage, no prevention, bearing rust, etc., and achieve the effect of low affinity and low compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

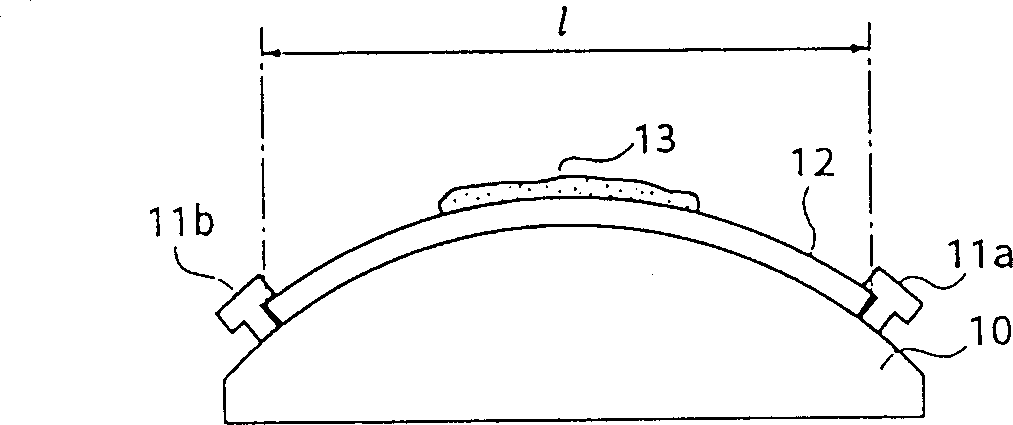

[0051] Embodiments involved in the present invention will be further described below with reference to the accompanying drawings.

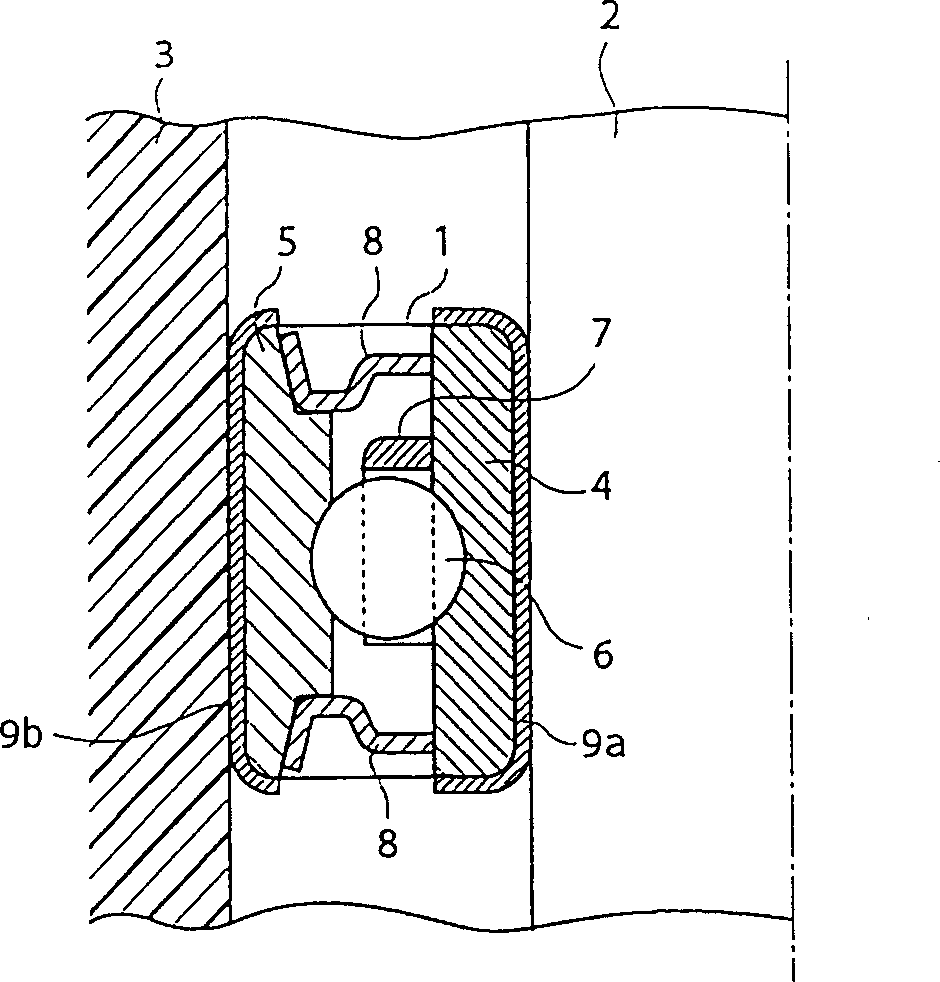

[0052] figure 1 It is a sectional view illustrating the rolling bearing of the present invention. The rolling bearing 1 is installed between the shaft 2 and the bearing housing 3 .

[0053] In somewhat more detail, a rolling bearing 1 comprises an inner ring 4 fixed to a shaft 2, an outer ring 5 fixed in a housing 3, a number of rolling elements 6 interposed between the inner ring 4 and the outer ring 5, holding these rolling elements 6 The retainer 7 separated from each other at a predetermined interval, and the seal plate 8 prevents the grease filled in the bearing as a lubricant from leaking out.

[0054] Formed on the outer surface of the outer ring 5 and the inner surface of the inner ring 4 are antirust films 9a and 9b formed of an oil-resistant material, respectively.

[0055] In some detail, as the resin material of the bearing housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com