Sensor for obtaining scoria flow-out signal during steel ladle casting

A sensor and steel casting technology, applied in the direction of material impedance, material magnetic variable, etc., can solve the problem of high cost and achieve the effect of low cost, simplified structure requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

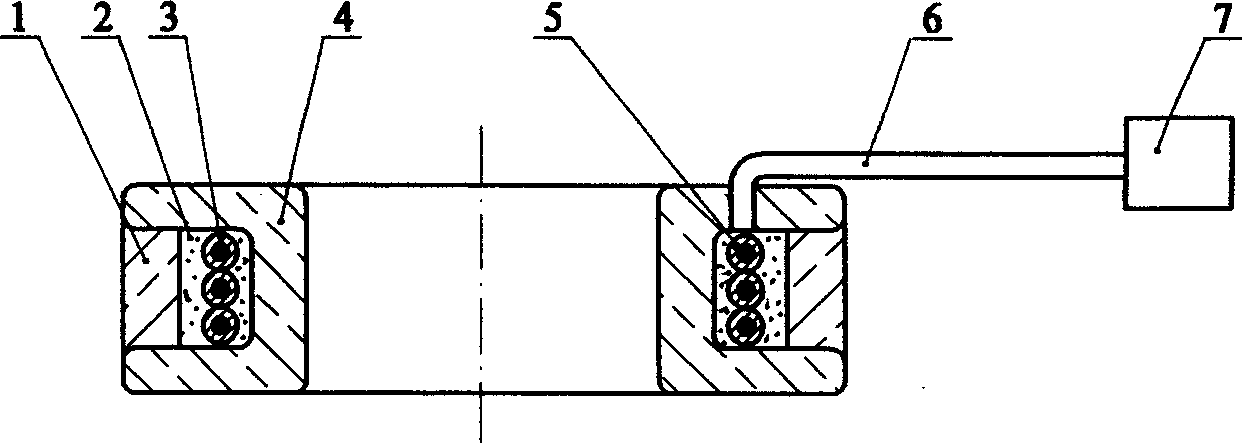

[0009] figure 1 It is a structural principle diagram of the present invention. The sensor frame 4 is made of high-quality refractory material, and its shape is an I-shaped ring. A spiral coil 3 is wound in the I-shaped groove, and the coil wire is covered with an insulating magnetic tube 5, and the surrounding is filled with a heat insulating material 2, and the rest Fill the refractory mud 1 in the I-shaped groove of the steel pipe, the double-core high-temperature cable 6 is embedded in the skeleton 4 in advance, and then the whole is dried and formed.

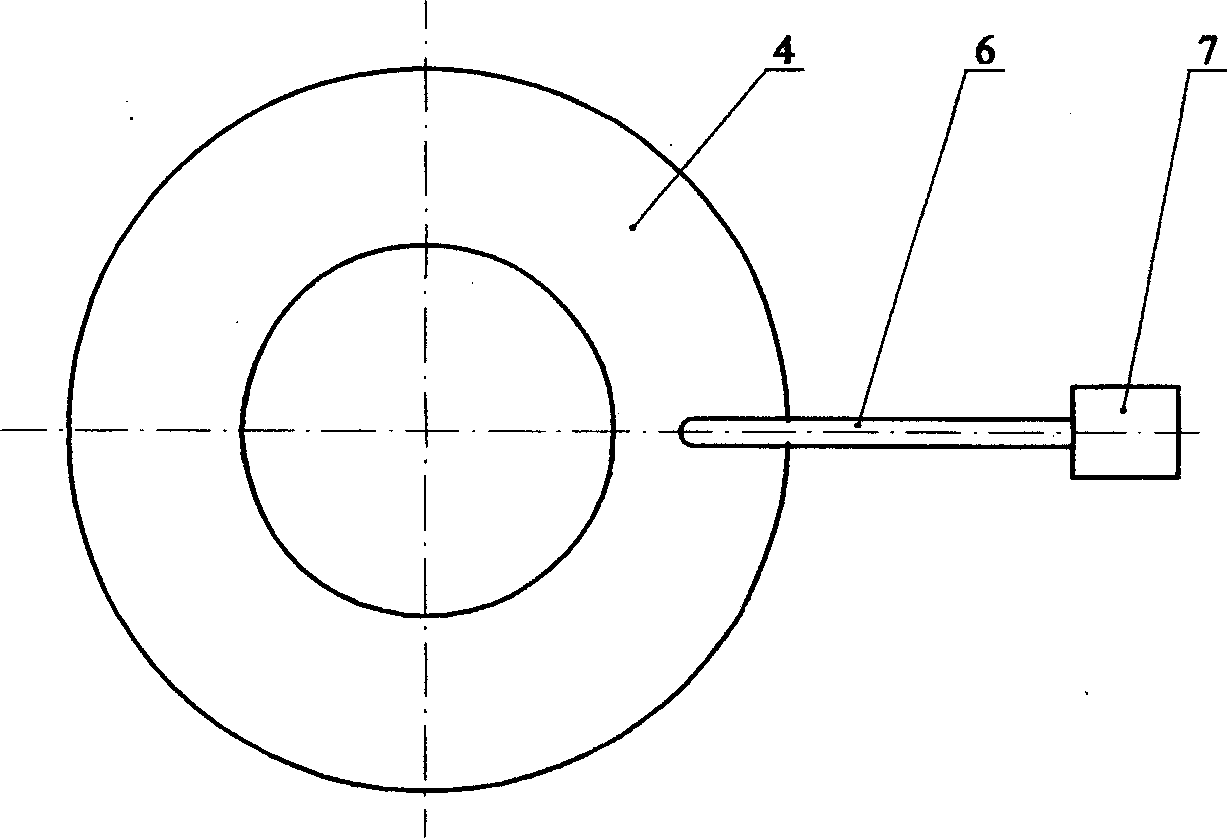

[0010] The shape of the finished sensor is a ring made of resistant material, such as figure 2 shown. The wire ends of the double-core high-temperature cable 6 and the coil 3 pass through after being welded inside the skeleton 4 . The sensor is installed at the outlet of the ladle, and the high-temperature cable 6 passes through the ladle shell to connect with the connector box 7 mounted on the ladle shell.

[0011] i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com