Formwork for cylindrical columns

A cylindrical, formwork technology, applied in the direction of pillars, formwork/formwork members, formwork/formwork/work frame, etc., can solve problems such as unpopularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

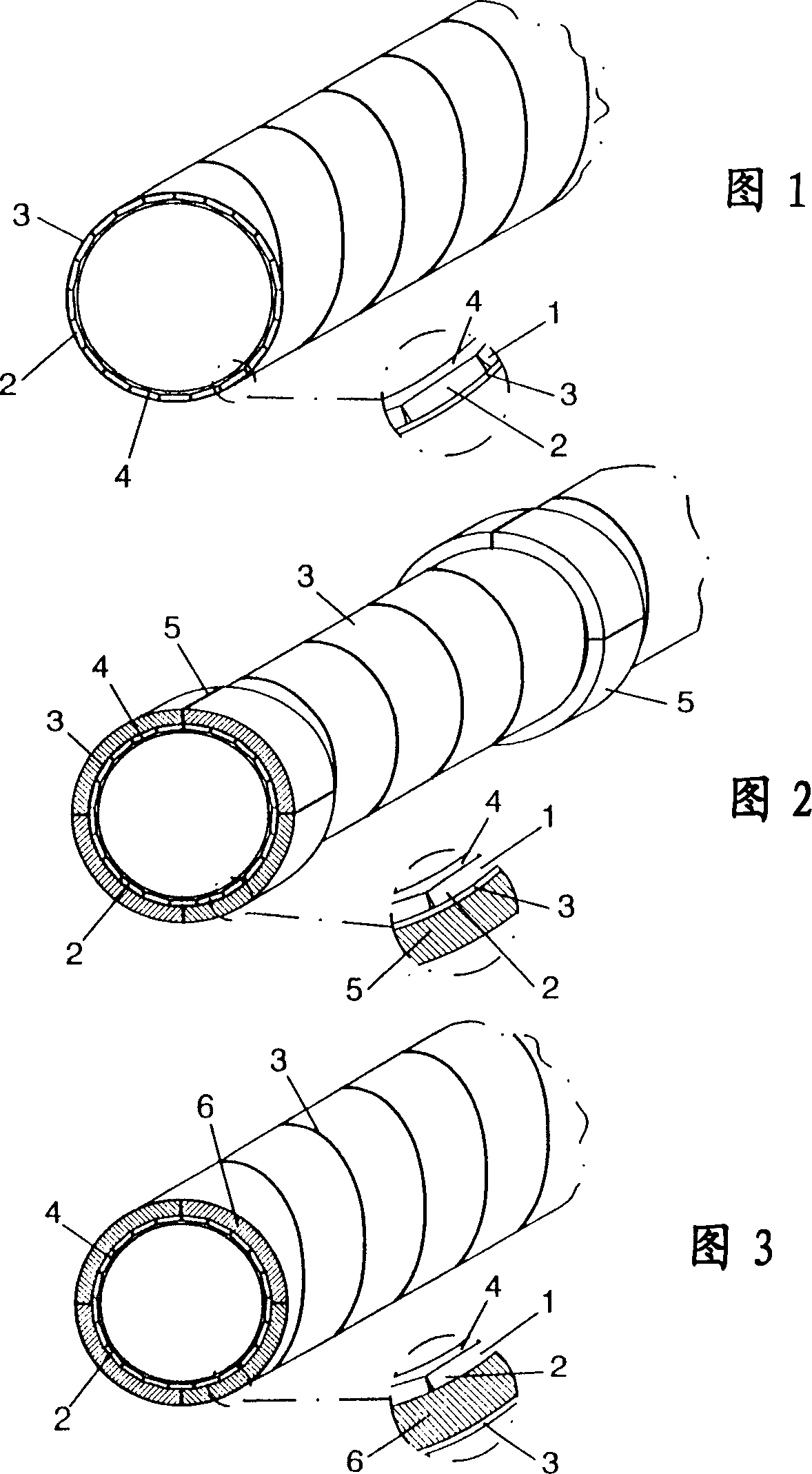

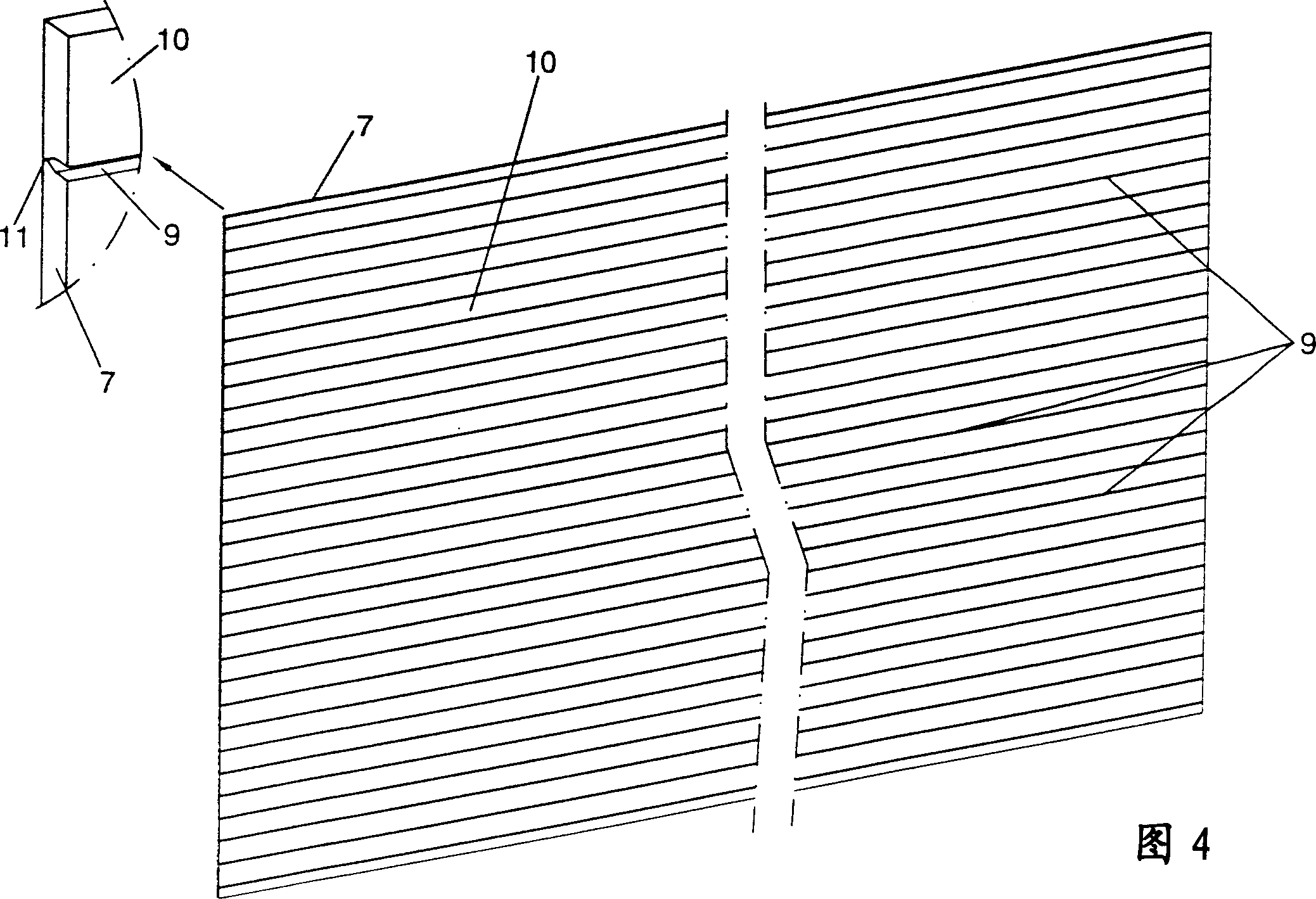

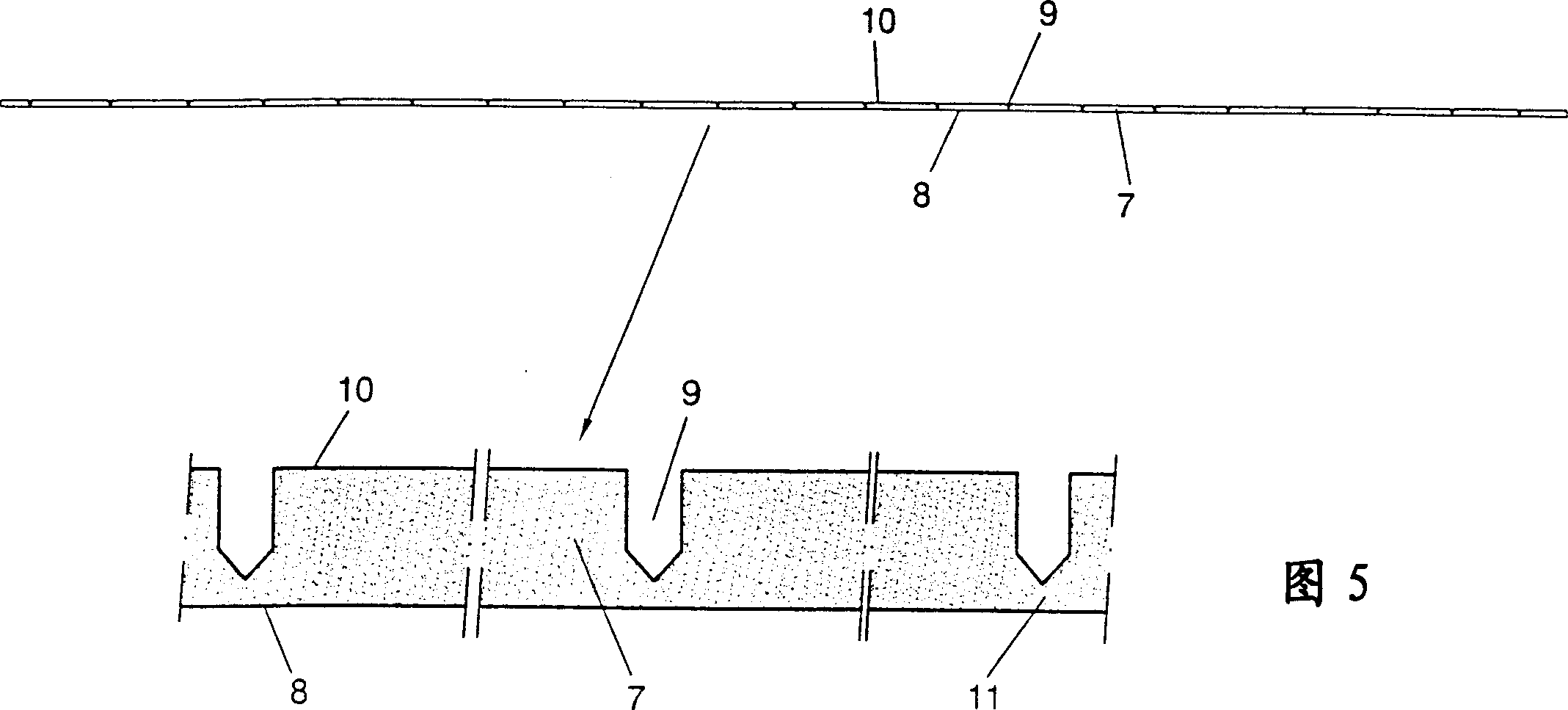

[0027] With reference to the drawings and more specifically to FIG. 1 , the formwork of the invention is constructed in its simplest embodiment as having an annular body ( 1 ) made of a plurality of rigid laminate plates ( 2 ), which Plasticized wood can be used as mentioned above or manufactured from hard plastic; they can be straight, in which case their width will be minimal in order to get good circumferential alignment when they are all bonded to each other, but they can also It can have a certain curvature according to the pillar to be obtained. The annular body (1) is suitably stabilized by means of a fiberglass mesh (3) rolled up in a helical shape on its outside and is also perfectly sealed by a self-adhesive inner film (4) which is continuously Cover the entire inner surface of the annulus (1).

[0028] A formwork constructed in this way is perfectly suitable for obtaining a cylindrical column with a diameter according to the formwork; the formwork, while being holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com