Large-amplitude centrifugal vibrating grinder

A vibrating mill and large-amplitude technology, which is applied in grain processing and other directions, can solve problems such as multi-axis eccentricity mutual interference, high equipment precision requirements, and impact on equipment life, so as to improve grinding ability, improve operating process performance, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

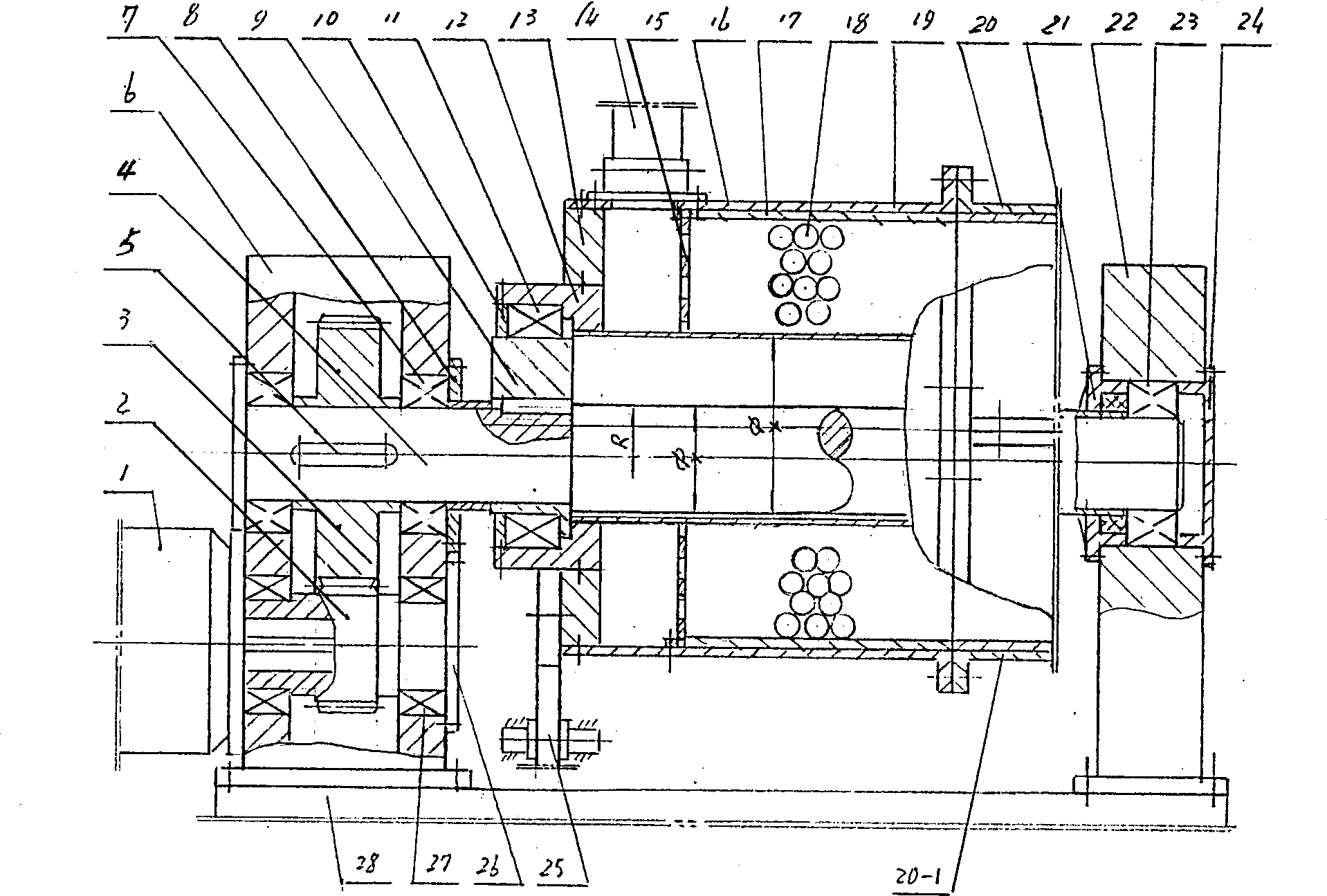

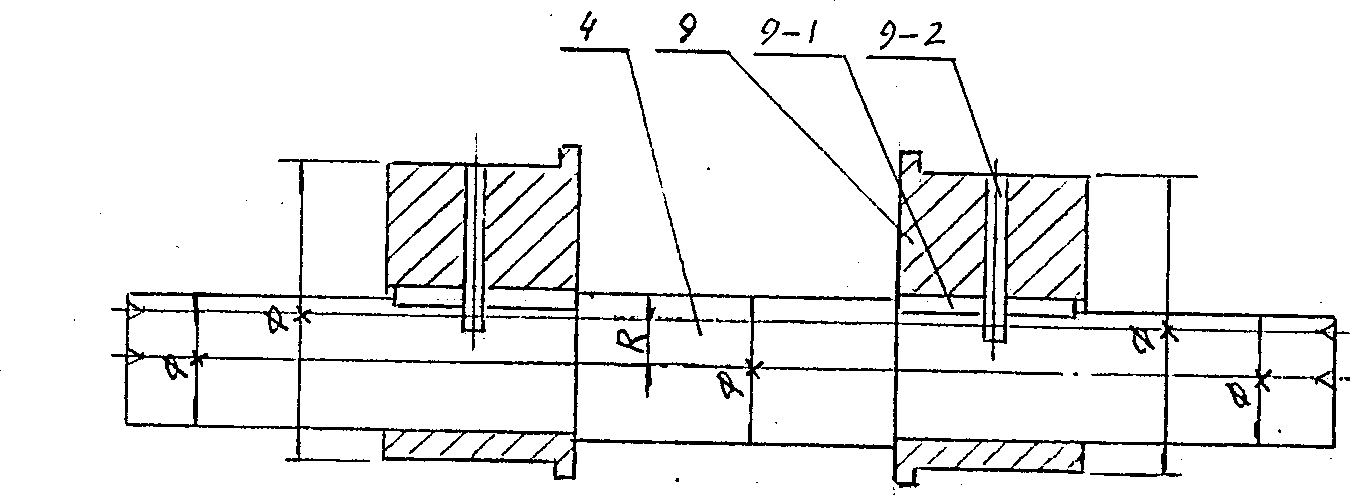

[0036]Embodiment 1, open-circuit large-amplitude centrifugal vibratory mill, there can be one barrel or multiple barrels, each barrel is equipped with an eccentric main shaft and a set of gear rotation system, and the whole mill is driven by the motor 1, The motor drives the main gear shaft 2 to drive the eccentric main shaft gear 3, the eccentric main shaft gear and the eccentric main shaft 4 rotate synchronously, and the eccentric part bearing 11 of the eccentric main shaft pushes the integral barrel or the three-section barrel to make large-amplitude centrifugal circular vibration. Because the support rod 25, the square key 29, and the support rod system of the bearing roller 30 are installed on the side of the barrel, the rotation of the barrel is limited, and it can only vibrate up, down, left, and right in a centrifugal circle. The ball 18 also vibrates accordingly, the medium ball revolves along the wall of the barrel and rotates at high speed, and the material is ground...

Embodiment 2

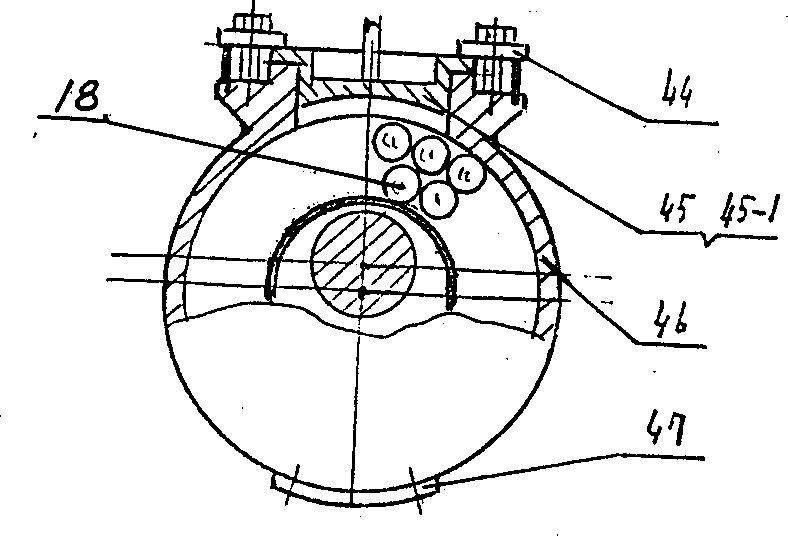

[0037] Embodiment 2, closed-circuit large-amplitude centrifugal vibratory mill, the barrel can also be one or more, its structure and movement principle are the same as in Example 1, except that the inlet and outlet of the barrel are the same mouth, and the timed feeding Material, timed discharge. On the upper part of the material barrel is a grid-shaped structure of the material inlet and outlet 45, the material inlet and outlet cover 45-1 is arranged on the material inlet and outlet, and the medium ball inlet and the cover 47 are located on the lower part of the material barrel. Airtight, so it is a closed barrel. When in use, first open the sealing cover of the medium ball inlet, put the medium ball 18 into the closed barrel 46, then seal it, then open the sealing cover of the material opening, load a certain amount of material, seal it again, and position the support rod 25 On the bearing roller 30, you can start grinding. After grinding, open the closed cover of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com