Anti-resonance type resonance screen

A resonant sieve and anti-resonance technology, which can be used in sieves, solids separation, grids, etc., to solve the problems of heavy machine weight, high failure rate of sieve boxes, and unsatisfactory service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

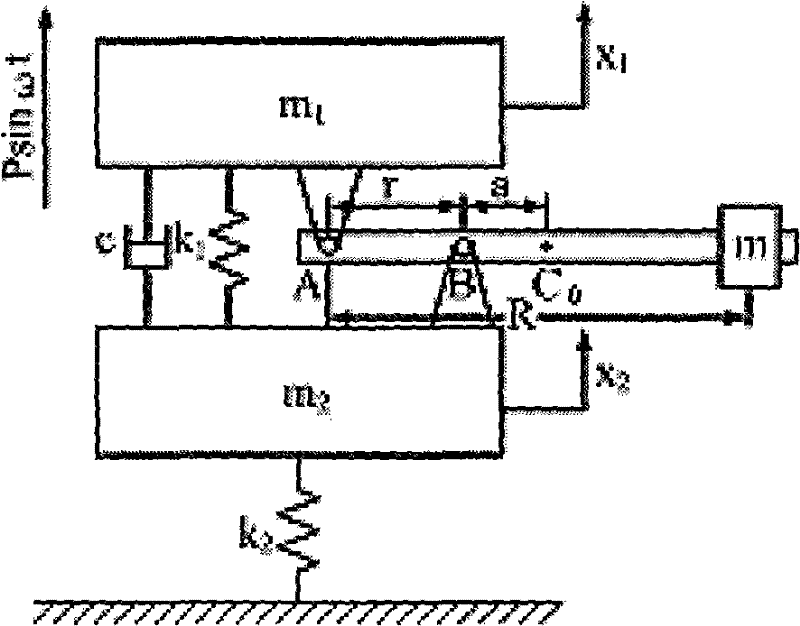

Method used

Image

Examples

Embodiment Construction

[0047] The detailed structure of the present invention is described in conjunction with the following examples and accompanying drawings.

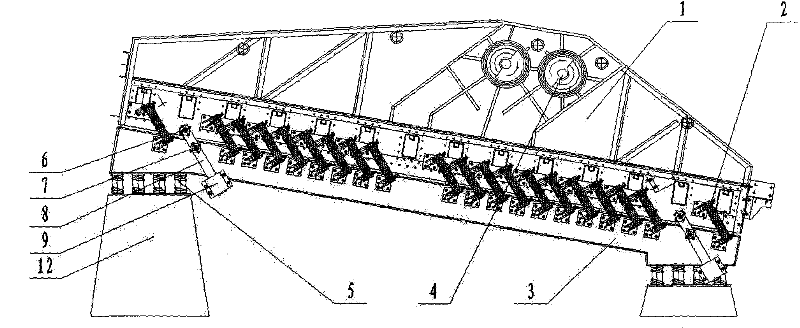

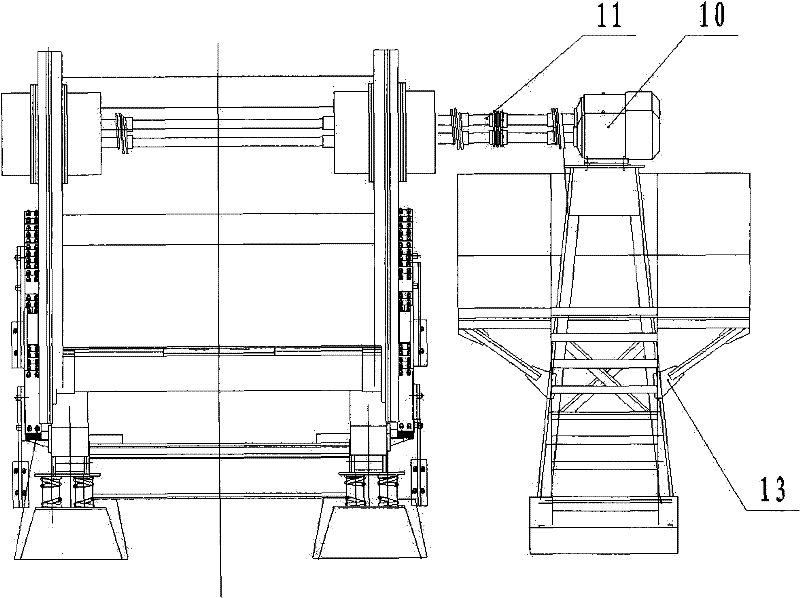

[0048] The structure of the present invention is as figure 2 with image 3As shown, the main vibration spring in this embodiment is a leaf spring. The upper plastid 1 is the working part of the anti-resonance resonant screen, the lower plastid 3 is the balance body, the upper plastid 1 and the lower plastid 3 are connected by the plate spring 2, and the lower plastid 3 is seated by the vibration isolation spring 5 On the foundation 12, the motor 10 is installed on the motor bracket 13, and is connected with the vibrator 4 through the transmission shaft 11; a lever 8 and a counterweight 9 are also installed between the upper mass body 1 and the lower mass body 3, and the counterweight It is 5‰ of the mass of the upper plastid. The lever 8 is connected to the upper body 1 through a rubber hinge 6, and the lever 8 is connected to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com