Wavelength conversion method, wavelength conversion laser, and laser beam machining apparatus

A wavelength conversion and laser beam technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of laser beam scanning direction and polarization direction deviation, machining result deviation, etc., to achieve high efficiency, homogeneity and uniformity , the effect of efficient machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

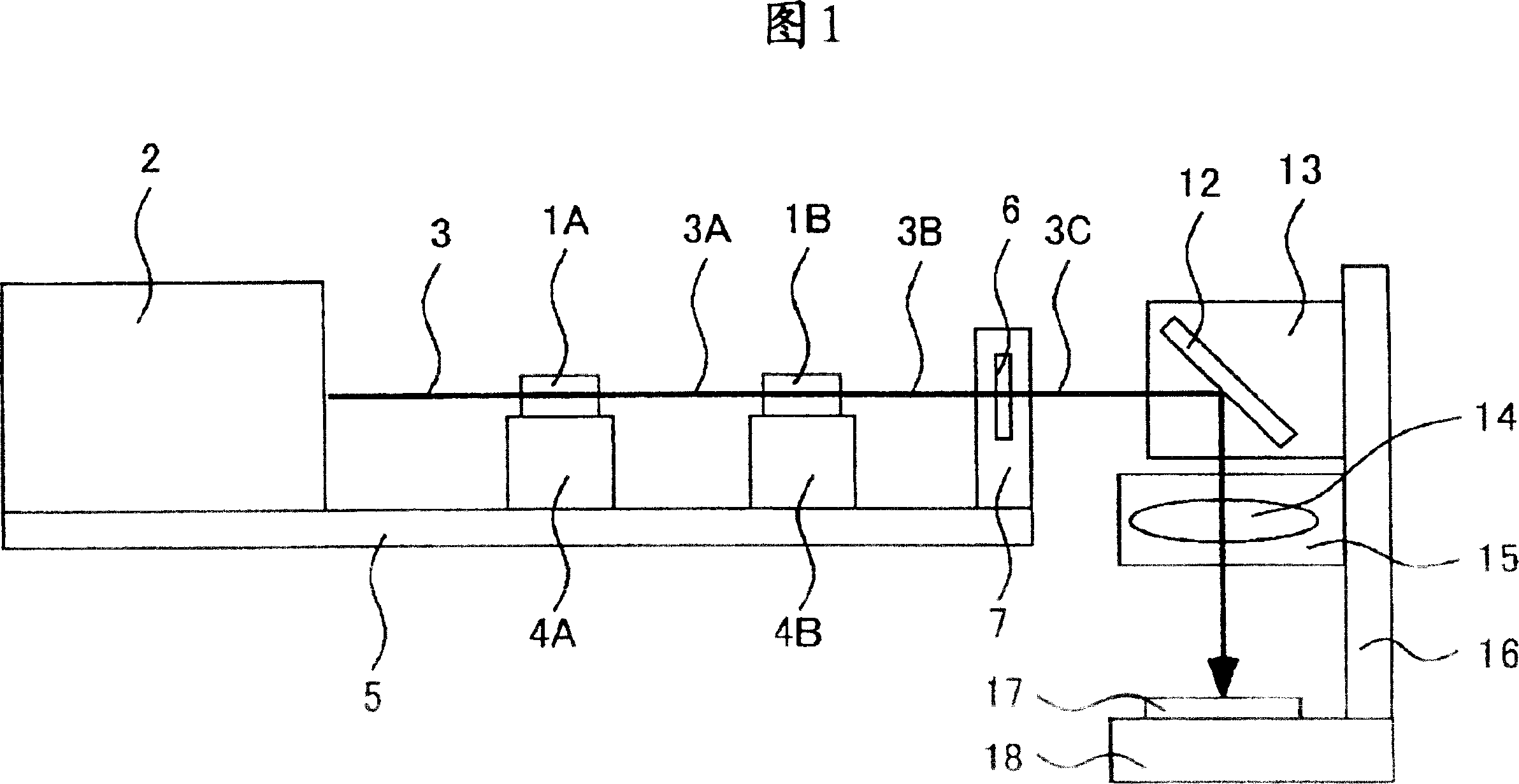

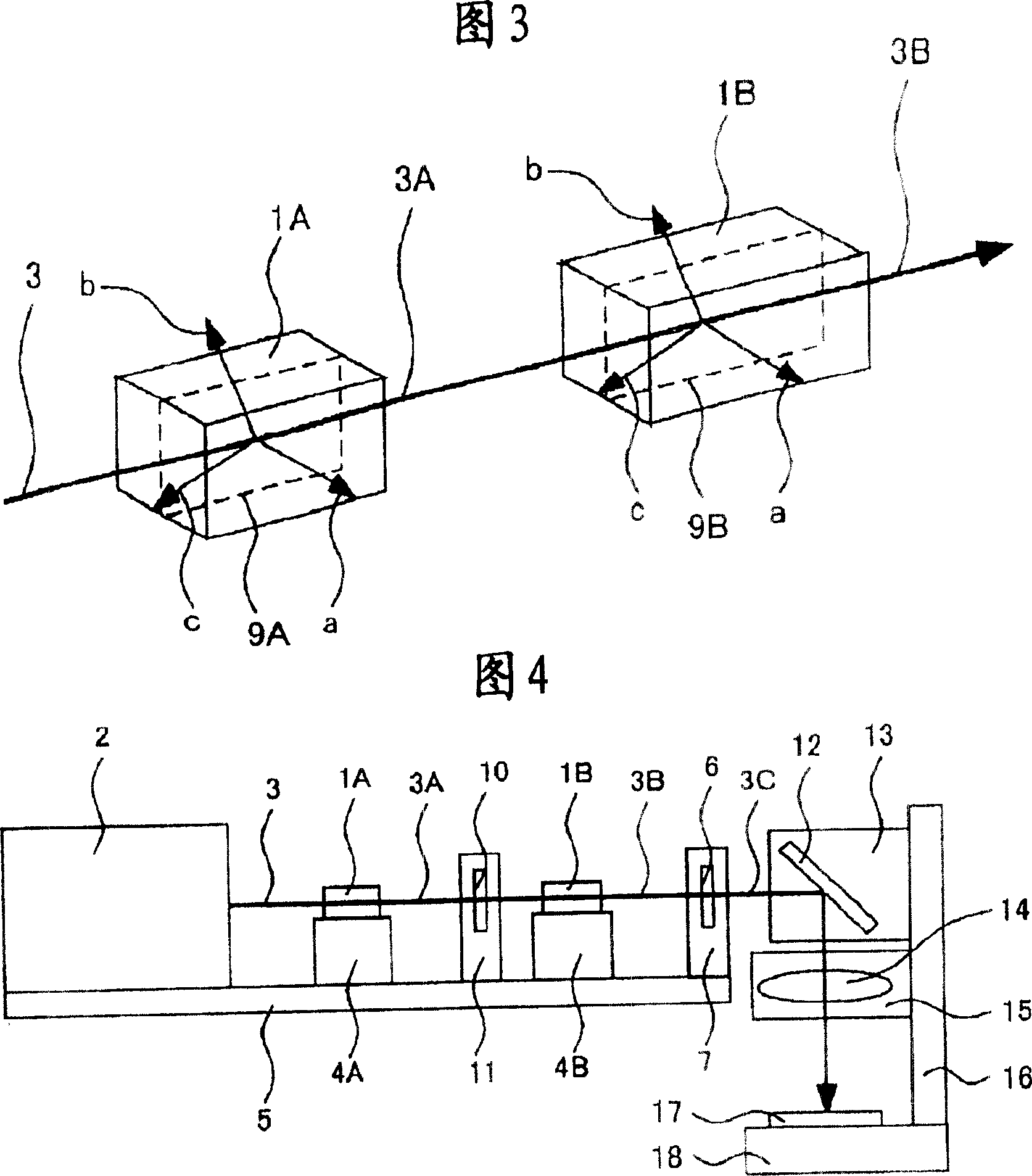

[0065] A Nd (neodymium):YAG laser that performs Q-switched pulse vibration and generates a fundamental laser beam with a wavelength of 1064 nm is used as a laser source 2 . The technical indicators of laser beam 3 include average power 529W, pulse cycle frequency 4kHz, pulse width 40.4ns, beam quality M 2 .10.

[0066] Use lithium borate (chemical formula: LiB 3 o 5 ) as wavelength conversion crystals 1A, 1B in which lithium borate generates second harmonics through phase matching of the second type, wherein the lengths of the crystals are 15 mm and 18 mm relative to the direction in which the laser beam passes through each crystal. Each crystal is located at 1 / e of the elementary laser beam 3 2 at the radius; that is, at 0.54 mm and 0.52 mm.

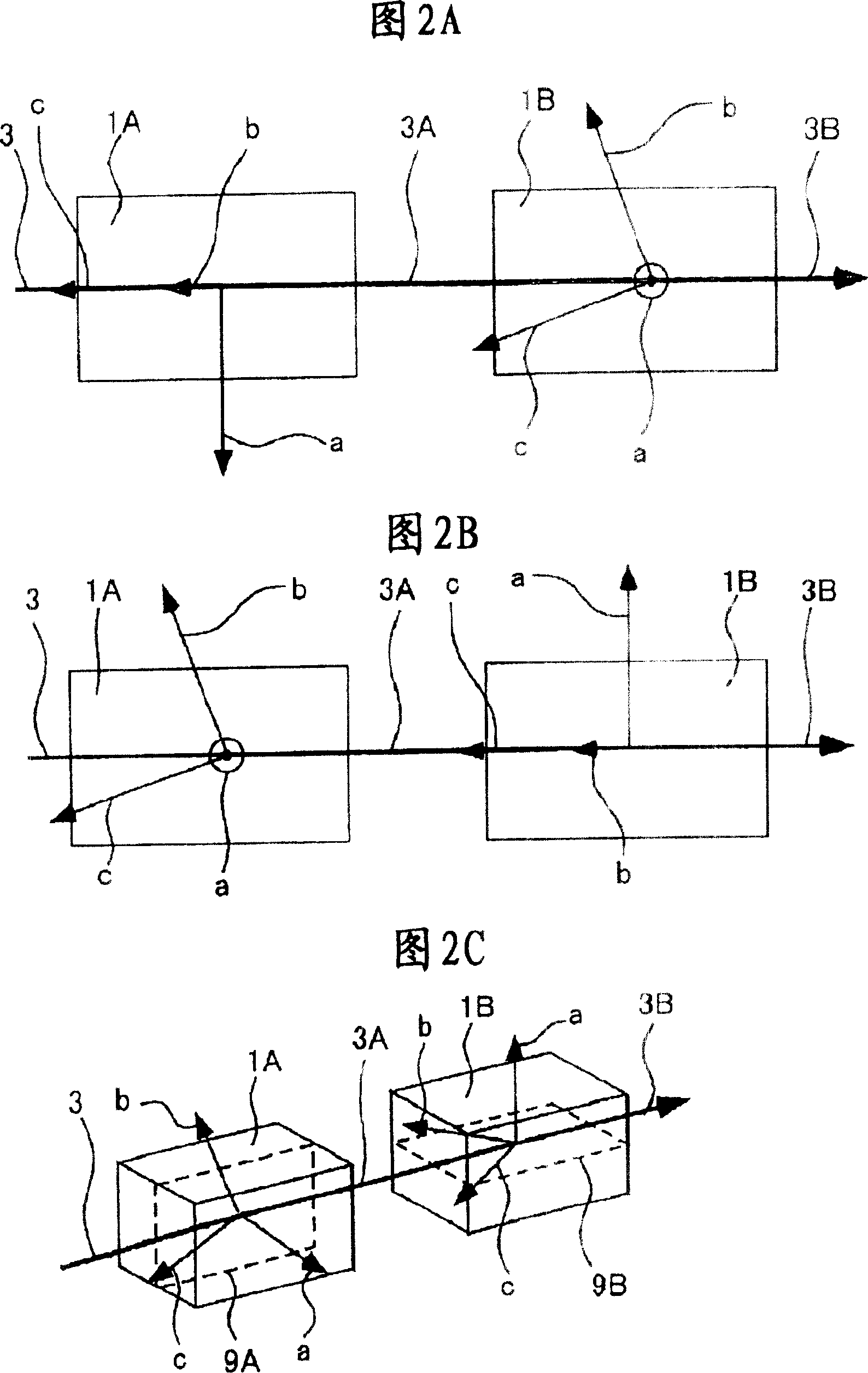

[0067] When the crystal direction axis "a" of the wavelength conversion crystal 1A is placed horizontally and the crystal direction axis "a" of the wavelength conversion crystal 1B is placed vertically, as shown in FIG. 2, the laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com