Double seal valve

A double seal and valve technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of small opening power, huge opening power, etc., to reduce the volume and the requirements for the power source, reduce the manufacturing cost, design and Create easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

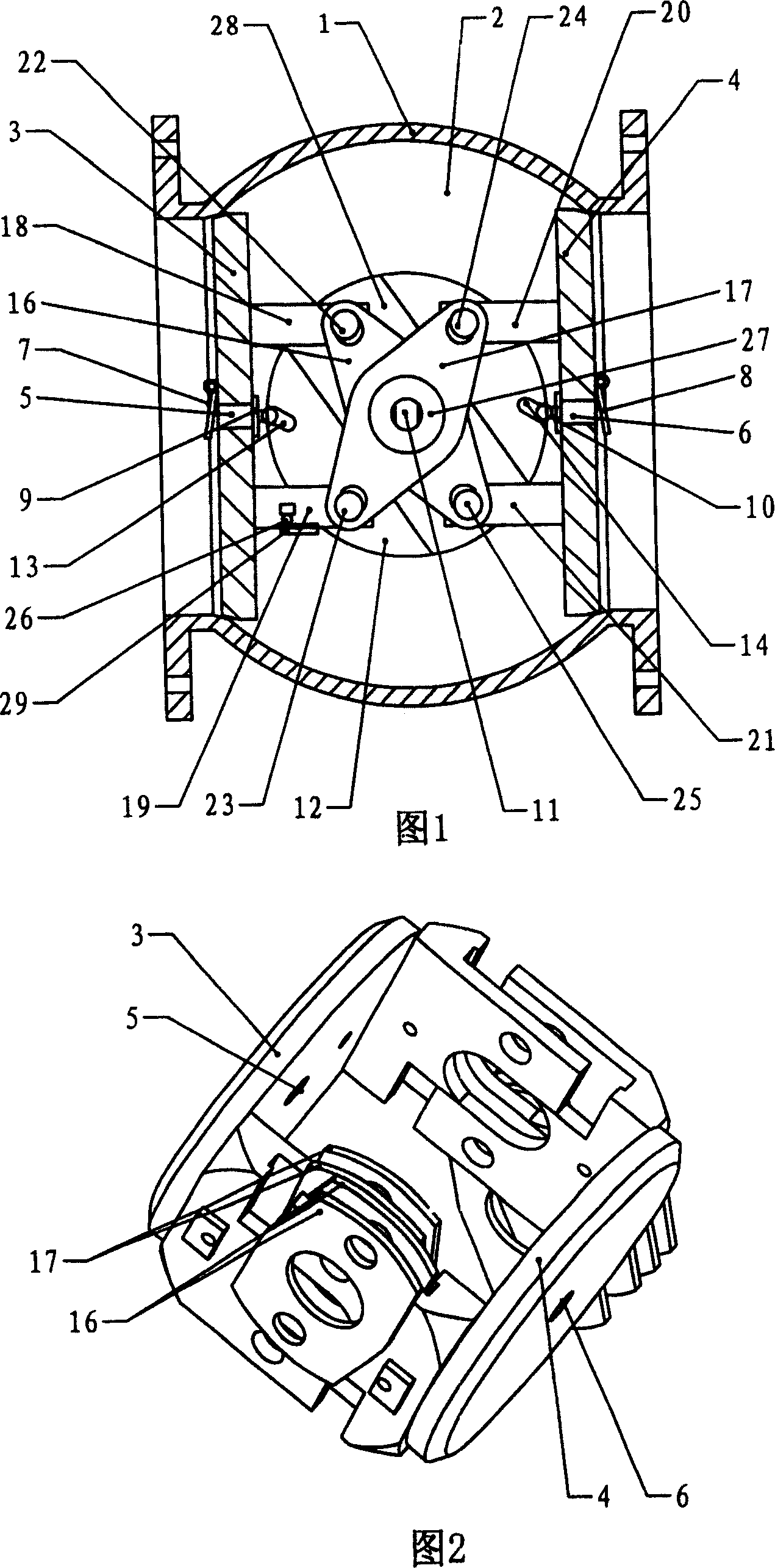

[0031] As shown in Figure 1 and Figure 2, the double-sealed valve includes a valve body 1 with an inlet and outlet, and two seals 3 and 4 that are arranged in the valve cavity 2 of the valve body 1 and match the inlet and outlet respectively. 3 and 4 are valve plates. Pressure relief holes 5 , 6 are respectively opened on the sealing members 3 , 4 , and matching one-way valves 7 , 8 and pressure relief hole sealing bodies 9 , 10 are arranged on the pressure relief holes 5 , 6 . Check valve 7,8 is arranged on pressure relief hole 5,6 channel and its direction is to prevent fluid from entering valve chamber 2. In the middle of the valve cavity 2, there is a rotary valve stem 11 and a drive plate 12 that is connected to the rotary valve stem 11. The drive plate 12 is provided with two slide grooves 13, 14, and the balls of the two pressure relief hole sealing bodies 9, 10. The head-shaped ends are respectively arranged in the slots 13 , 14 and fitted thereto. In this way, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com