Hyperpure water manufacturing systems

A manufacturing system and ultra-pure water technology, applied in water/sewage treatment, non-polluted water treatment, light water/sewage treatment, etc., can solve problems such as products without structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The specific implementation, structure, features and functions of the ultrapure water production system proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

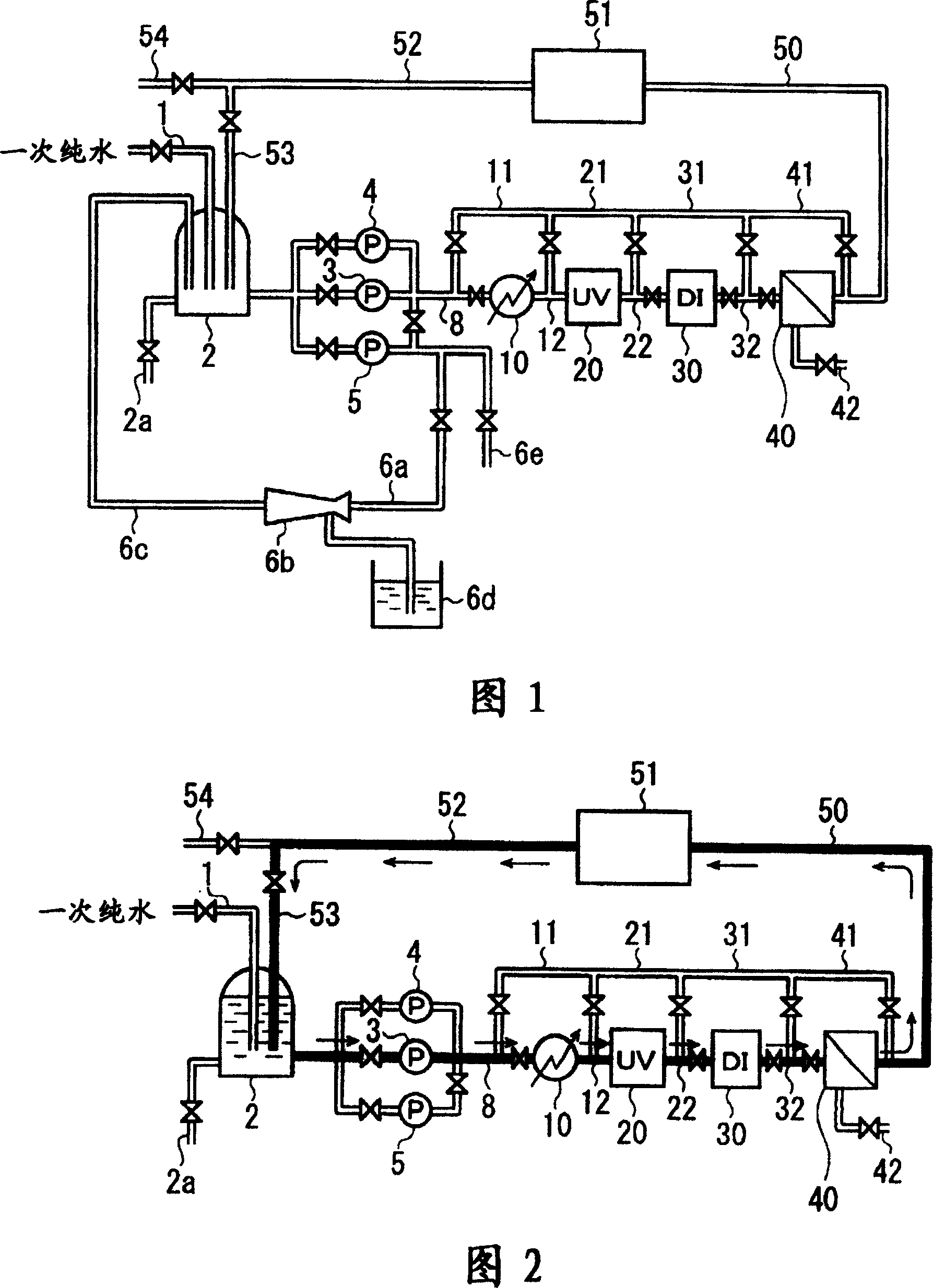

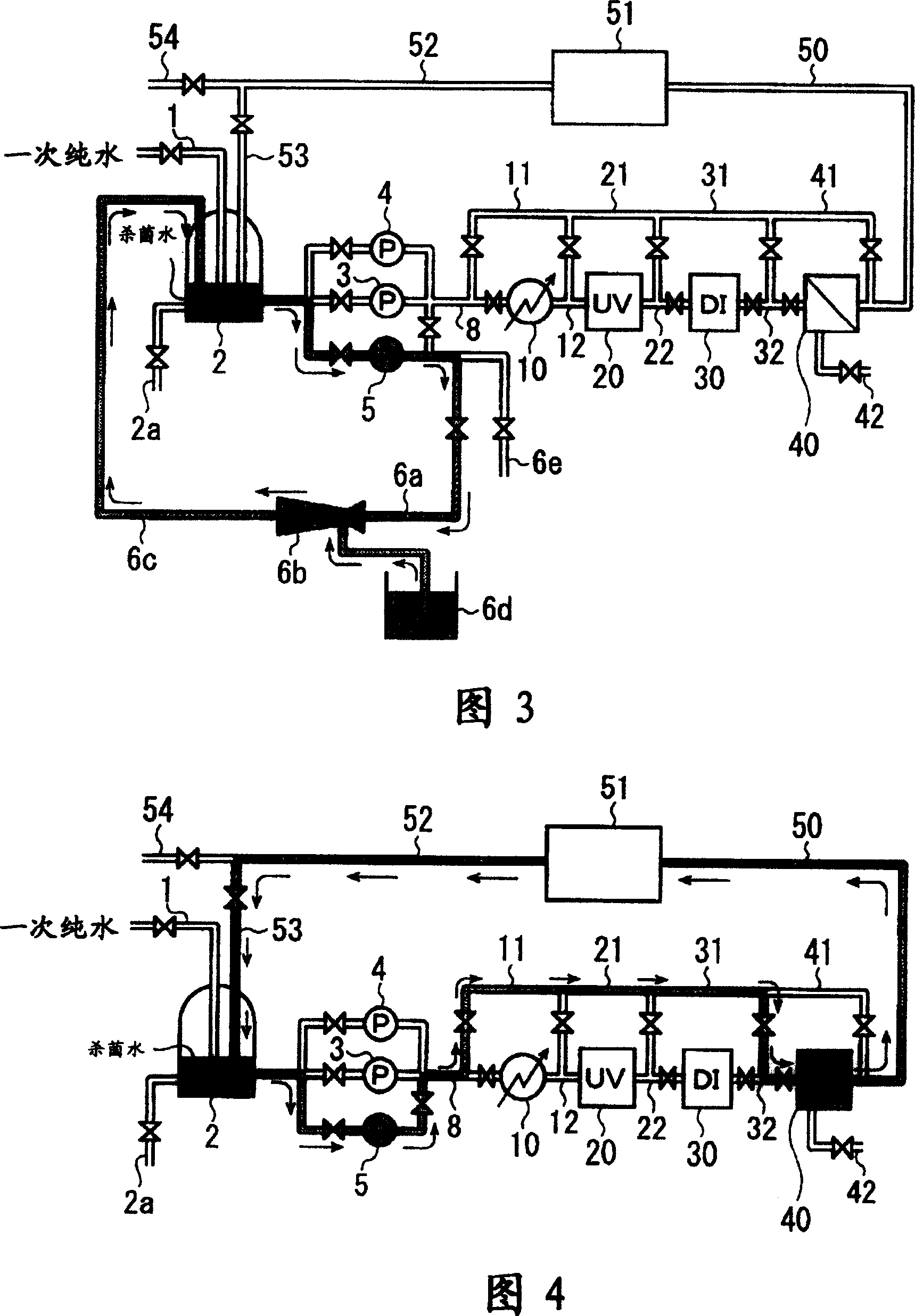

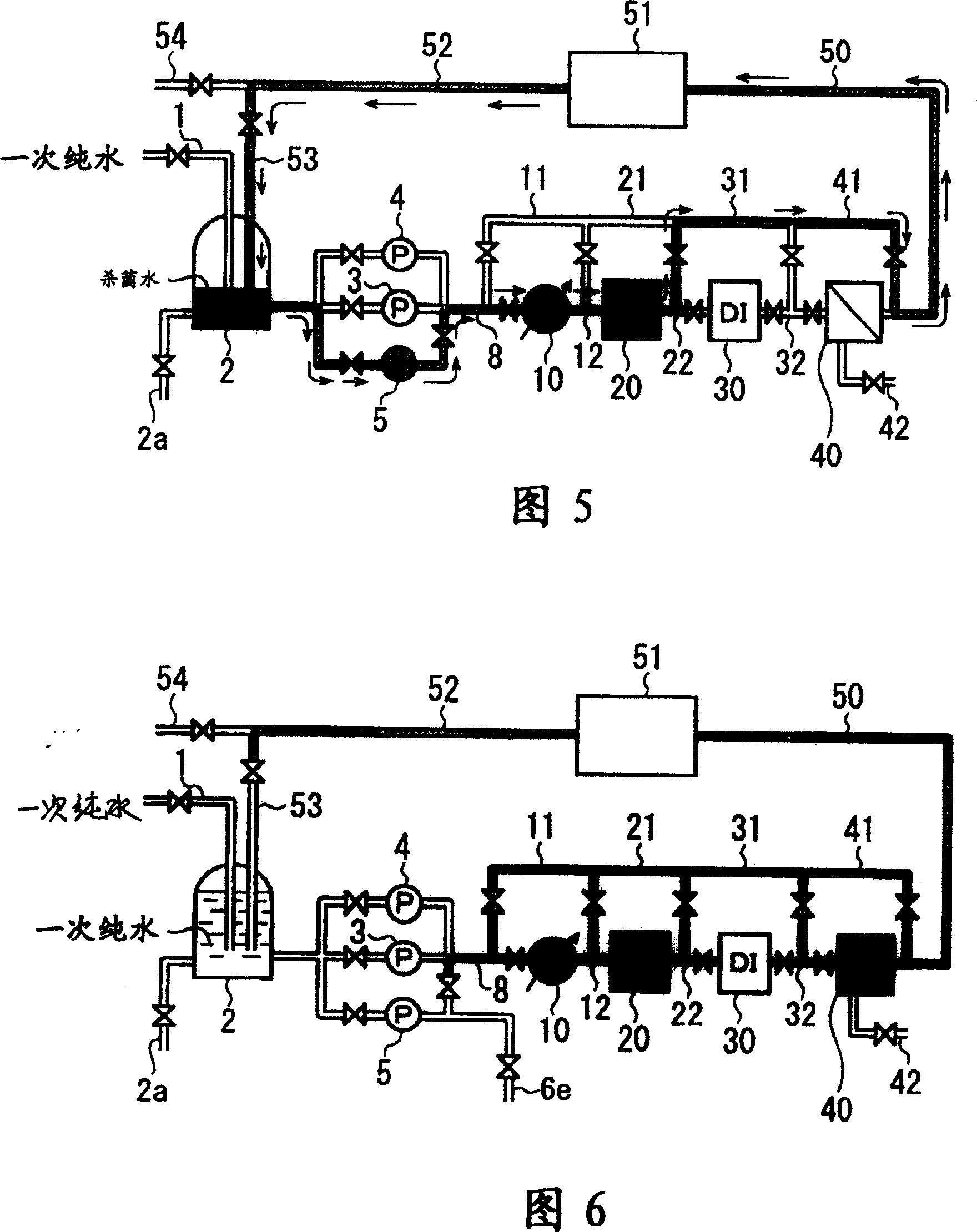

[0080] Please refer to FIG. 1 , which is a system diagram of an embodiment of the ultrapure water production system of the present invention. The primary pure water is supplied to the secondary storage tank 2 from the pipe 1 and stored. The water in the secondary storage tank 2 is sent out by the pump 3 . Pump 4 is a backup pump and is arranged in parallel with pump 3 . A dedicated sterilization pump 5 is arranged in parallel with the pumps 3 and 4 .

[0081] In addition, a drain line 6e used when draining water from the sub tank 2 is branched from the discharge ports of the pumps 3 and 4 .

[0082] The water sent out by the pump 3 or 4 through the pipe 8 sequentially passes through the heat exchange device 10 cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com