Printed circuit board for mounting a quad flat package IC, method of soldering a quad flat package IC, and air conditioning apparatus with such a printed circuit board

A technology of printed circuit board and welding method, applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, printed circuits, etc., can solve problems such as short circuits, reduce tin bridges, increase manual labor Correction of work, effect of preventing solder short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiment 1

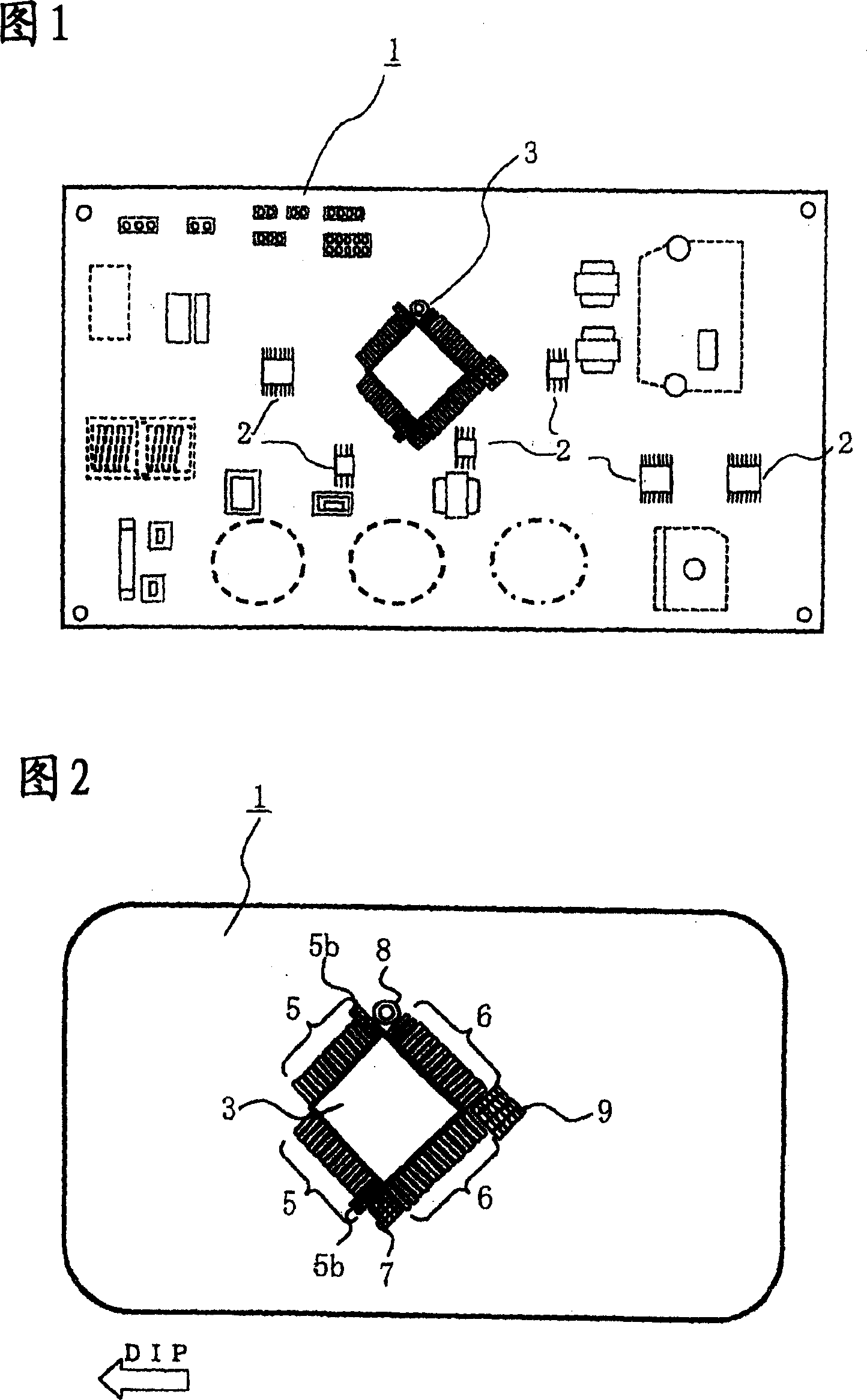

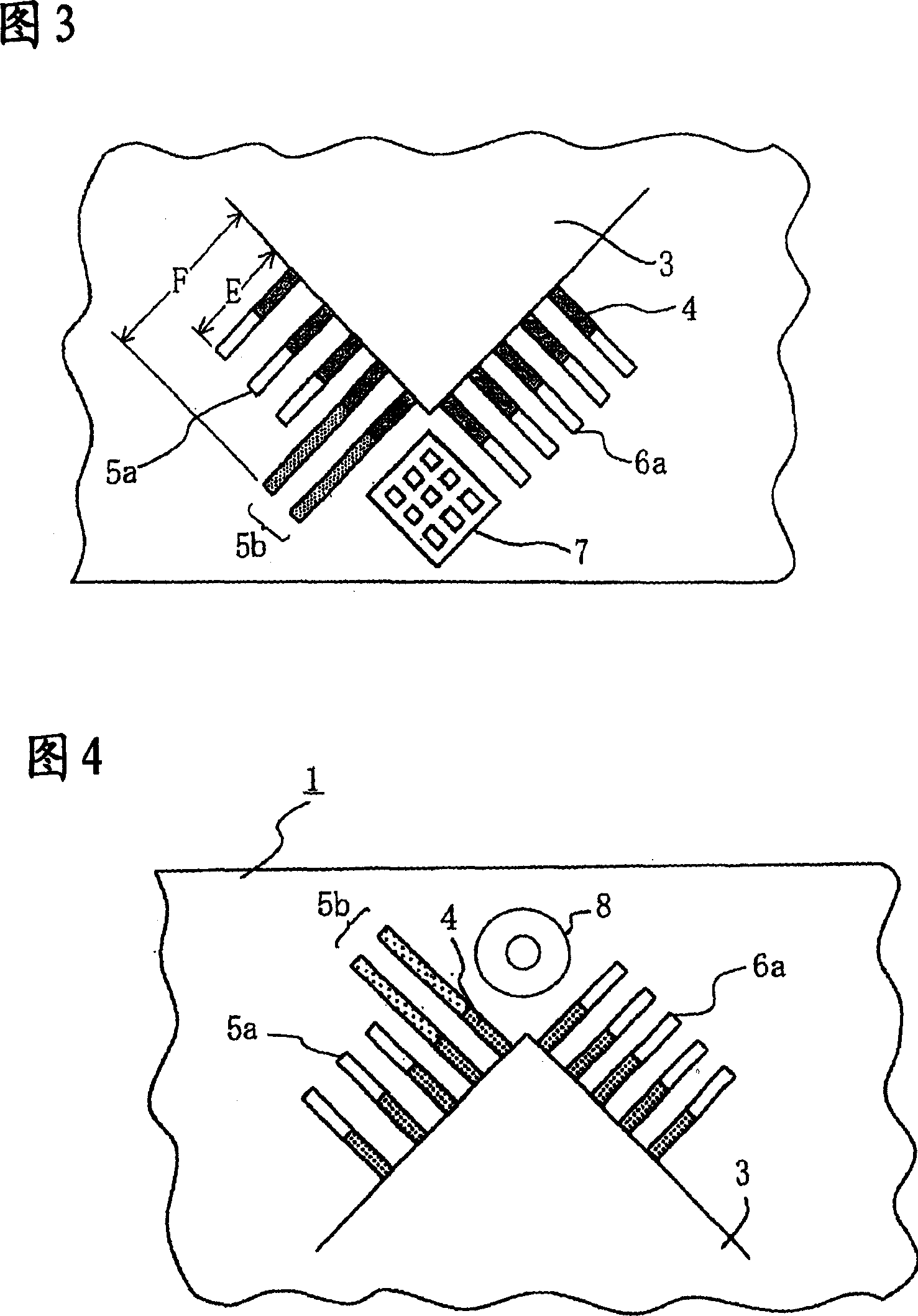

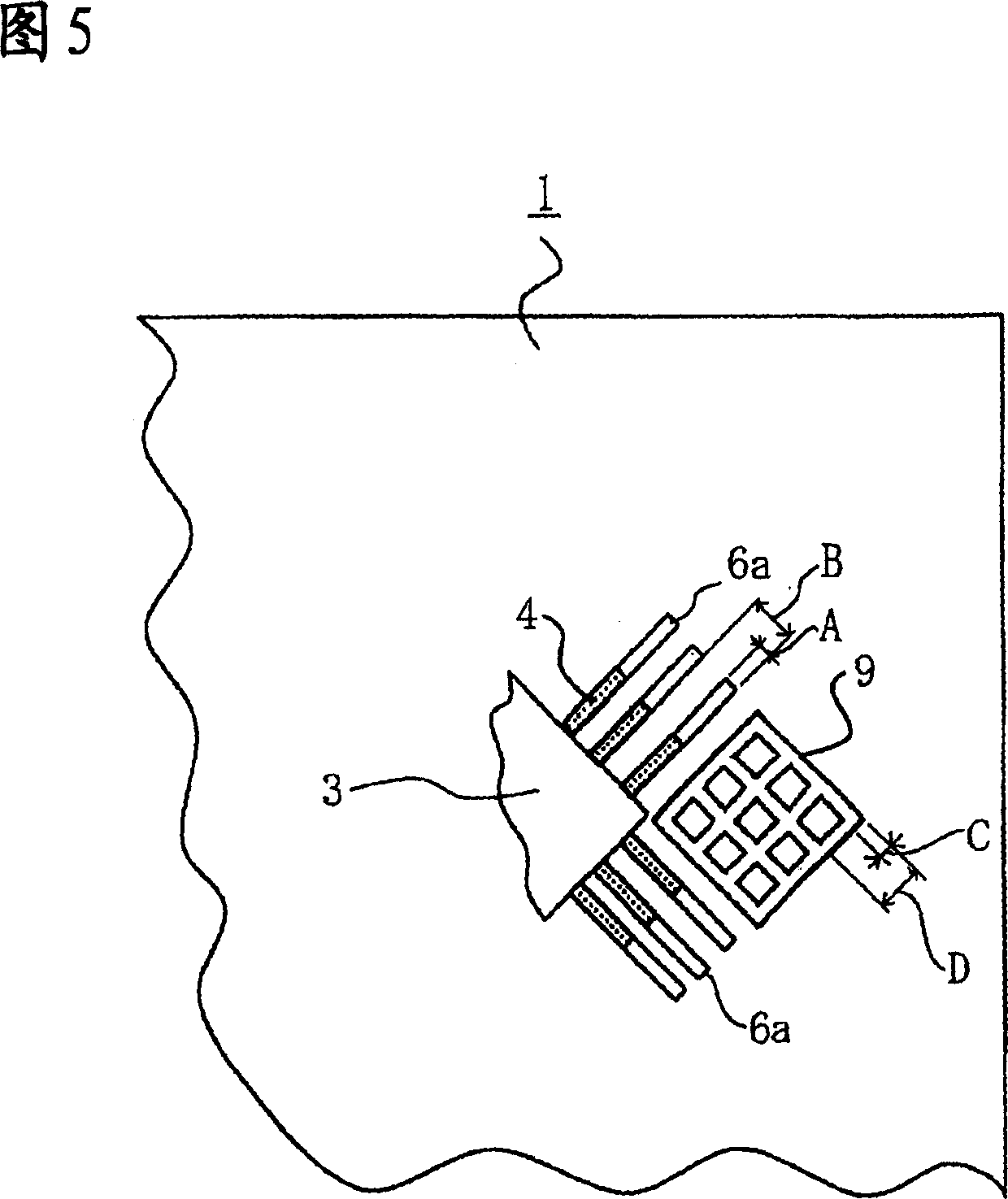

[0030] Next, a 4-direction pin flat package IC mounted printed wiring board according to Embodiment 1 of the present invention will be described with reference to FIGS. 1 to 4 . Here, the plan view of FIG. 1 shows a schematic configuration of a 4-direction pin flat package IC mounting printed wiring board according to Embodiment 1 of the present invention viewed from the back, and the plan view of FIG. 2 shows Embodiment 1 of the present invention. The 4-direction pin flat package IC, the enlarged plan view of the main part of Fig. 3 shows the front land group and the rear of the printed wiring board on which the 4-direction pin flat package IC according to Embodiment 1 of the present invention is mounted. The relationship on one side of the land group, the enlarged plan view of the main part of FIG. 4 shows another difference between the front land group and the rear land group of the 4-direction pin flat package IC mounting printed wiring board accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com