Electro-optical device and electronic apparatus

A technology of electro-optical device and main power supply, applied in the direction of electric light source, identification device, lighting device, etc., can solve the problems such as the decrease of brightness in the central part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

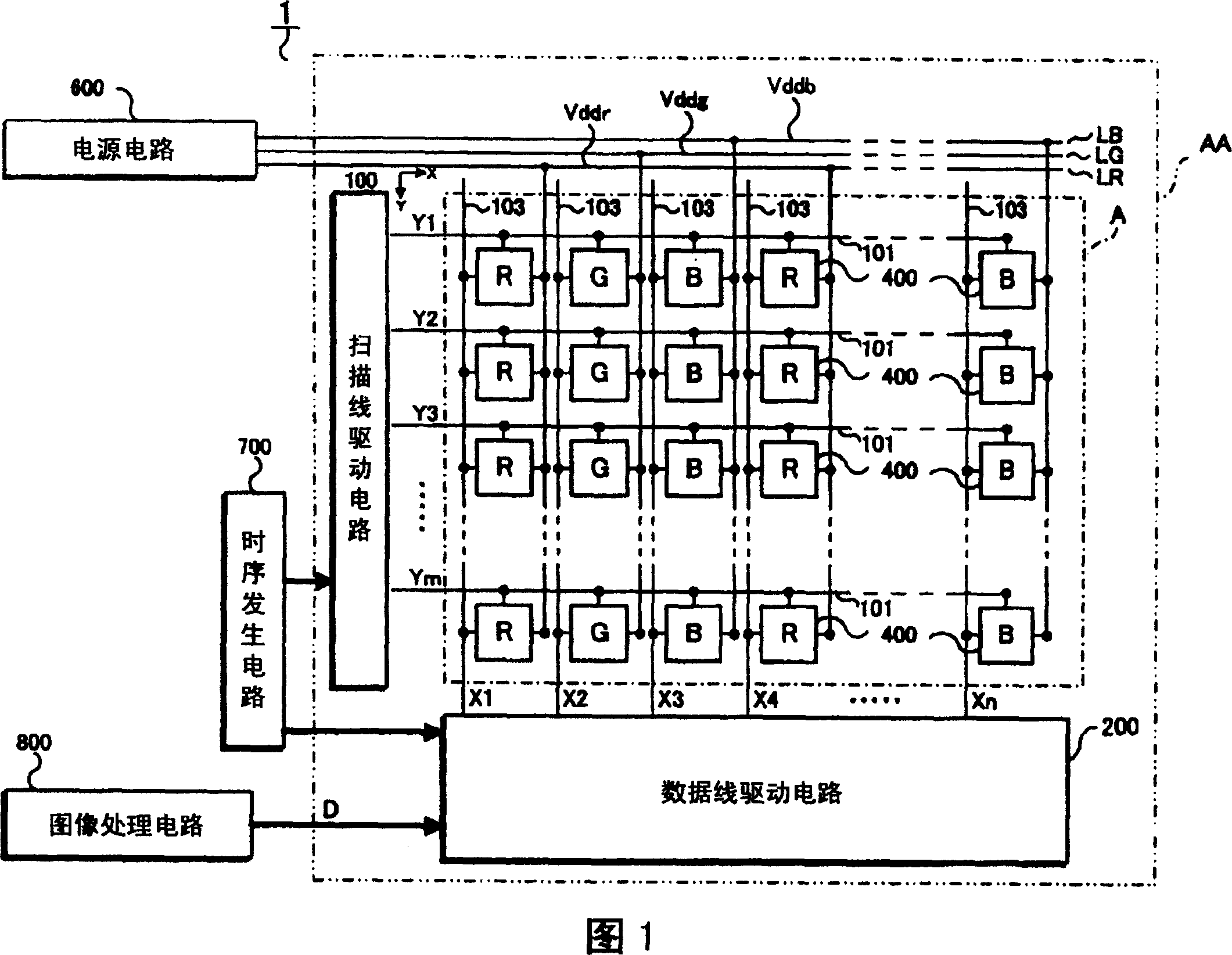

[0039] FIG. 1 is a block diagram showing a schematic configuration of an electro-optical device according to a first embodiment of the present invention.

[0040] The electro-optical device 1 includes an electro-optical panel AA and external circuits. A pixel region A, a scanning line driving circuit 100 and a data line driving circuit 200 are formed on the electro-optical panel AA. Wherein, in the pixel area A, m scanning lines 101 parallel to the X direction are formed, and n data lines 103 parallel to the Y direction are formed, and the Y direction is perpendicular to the X direction. Pixel circuits 400 are respectively provided corresponding to intersection points of the scanning lines 101 and the data lines 103 . The pixel circuit 400 includes an OLED element. The symbols "R", "G" and "B" shown in the figure indicate the emission color of the OLED element. In this example, pixel circuits 400 of various colors are arranged along the data line 103 .

[0041] Among the p...

no. 2 approach

[0052] Next, an electro-optical device 1 according to a second embodiment will be described. The electro-optical device 1 of the second embodiment has the same configuration as that of the electro-optical device 1 of the first embodiment, except that the power wiring of the same power supply voltage is commonly used for the R color and the B color. Although the electro-optical device 1 of the first embodiment presupposes that the luminous efficiency of the OLED element 420 is different for each luminous color, depending on the type of organic EL material used for the luminescent layer, the luminous efficiency is similar even if the luminous color is different. type of material. The electro-optical device 1 of the second embodiment is a device using, for example, an OLED element 420 having similar luminous efficiencies in R color and B color. As for color matching, those colors having similar voltage values when displaying white are matched with each other. For example, whe...

no. 3 approach

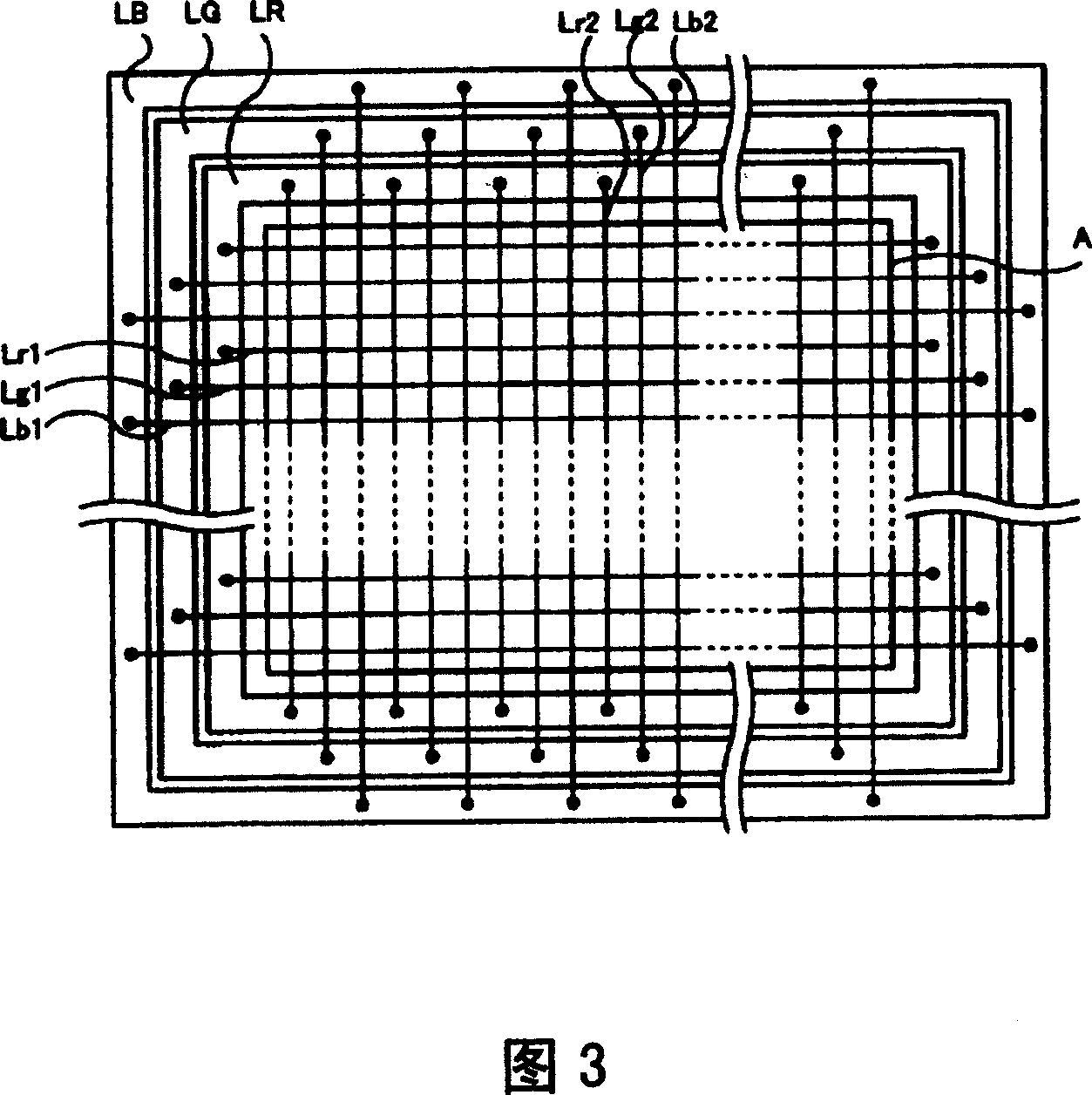

[0060] Next, an electro-optical device 1 according to a third embodiment will be described. The electro-optical device 1 of the third embodiment differs from the electro-optical device 1 of the first embodiment in using a monochromatic OLED element. Fig. 6 shows the detailed structure of the power supply wiring. In this case, since one type of power supply voltage is sufficient, the main power supply line constitutes only LW shown in the figure. Auxiliary power supply connection points P are all provided at locations corresponding to intersections of the first auxiliary power supply line Lw1 and the second auxiliary power supply line Lw2 . That is, the first auxiliary power supply line Lw1 and the second auxiliary power supply line Lw2 are arranged in a grid pattern, and the power supply impedance is significantly reduced by connecting them at these intersections. Therefore, a uniform power supply voltage can be supplied to each pixel circuit 400 .

[0061] However, the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com