Polymer mould method for preparing diaphragm of fluorine-contained polymen lithium ion cell

A technology of lithium-ion batteries and polymers, applied in battery components, circuits, membrane technology, etc., can solve problems affecting liquid absorption and battery conductivity, and achieve high porosity, large pore size, and uniform pore size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

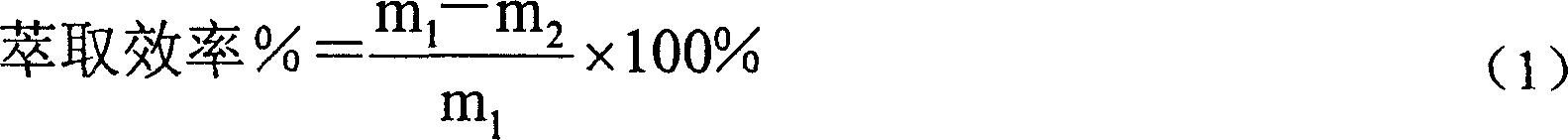

Embodiment 1

[0031] Prepare 10wt% fluorine-containing copolymer PVDF-HFP (Aldrich, USA, Mw=4.5×10 5 , Mn=1.3×10 5 ), 10wt% PVP (K30, China Pharmaceutical Group Shanghai Chemical Reagent Company, imported repackaging) acetone solution, mechanically stirred in a constant temperature water bath at 50°C to obtain a viscous casting solution. Vacuum defoaming for several hours and removal of impurities. Squeegee-coat the casting solution onto a clean glass plate with a scraper gap of 140-500 μm, expose it to air for 30 seconds, and then dry it in vacuum at 50°C until the solvent evaporates completely. At room temperature, the film prepared above was cut into a rectangle, and soaked in absolute ethanol for 24 hours. After natural drying at room temperature, the extraction efficiency was calculated by gravimetric method. The resulting film was quenched in liquid nitrogen, and vacuum-plated with gold to observe the structure of the surface and cross-section by scanning electron microscopy. Afte...

Embodiment 2

[0034] Prepare 25wt% fluorine-containing copolymer PVDF-HFP (Aldrich, USA, Mw=4.5×10 5 , Mn=1.3×10 5 ), 25wt% PVP (K30, China Pharmaceutical Group Shanghai Chemical Reagent Company, imported repackaging) acetone solution, mechanically stirred in a constant temperature water bath at 50°C to obtain a viscous casting solution. Vacuum defoaming for several hours and removal of impurities. Squeegee-coat the casting solution onto a clean glass plate with a scraper gap of 140-500 μm, expose it to air for 30 seconds, and then dry it in vacuum at 50°C until the solvent evaporates completely. At room temperature, the film prepared above was cut into a rectangle, and soaked in absolute ethanol for 24 hours. After natural drying at room temperature in a glove box filled with argon, moisture 2 6 / EC-DMC (volume ratio: 1:1) for 2 hours, the membrane was taken out between two pieces of filter paper to gently remove excess electrolyte on the surface of the membrane, and the liquid absorption ...

Embodiment 3

[0036] Prepare 10wt% fluorine-containing copolymer poly(vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene) (Aldrich, USA, Mw=4.5×10 5 , Mn=1.3×10 5 ), 10wt% PVP (K30, China Pharmaceutical Group Shanghai Chemical Reagent Company, imported repackaging) acetone solution, mechanically stirred in a constant temperature water bath at 50°C to obtain a viscous casting solution. Vacuum defoaming for several hours and removal of impurities. Squeegee-coat the casting solution onto a clean glass plate with a scraper gap of 140-500 μm, expose it to air for 30 seconds, and then dry it in vacuum at 50°C until the solvent evaporates completely. At room temperature, the film prepared above was cut into rectangles, soaked in absolute ethanol for 24 hours, and dried naturally at room temperature. In a glove box filled with argon, the moisture content was 2 6 / EC-DMC (volume ratio: 1:1) for 2 hours, the membrane was taken out between two pieces of filter paper to gently remove excess e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com