Oil extraction microbial conenoses nutrient solution

A technology of origin microorganisms and nutrient solution, applied in the field of chemical agents, can solve the problems of complicated fermentation of bacterial liquid, development and evaluation of bacterial species, etc., and achieve the effects of long effective period, low cost, and improved recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

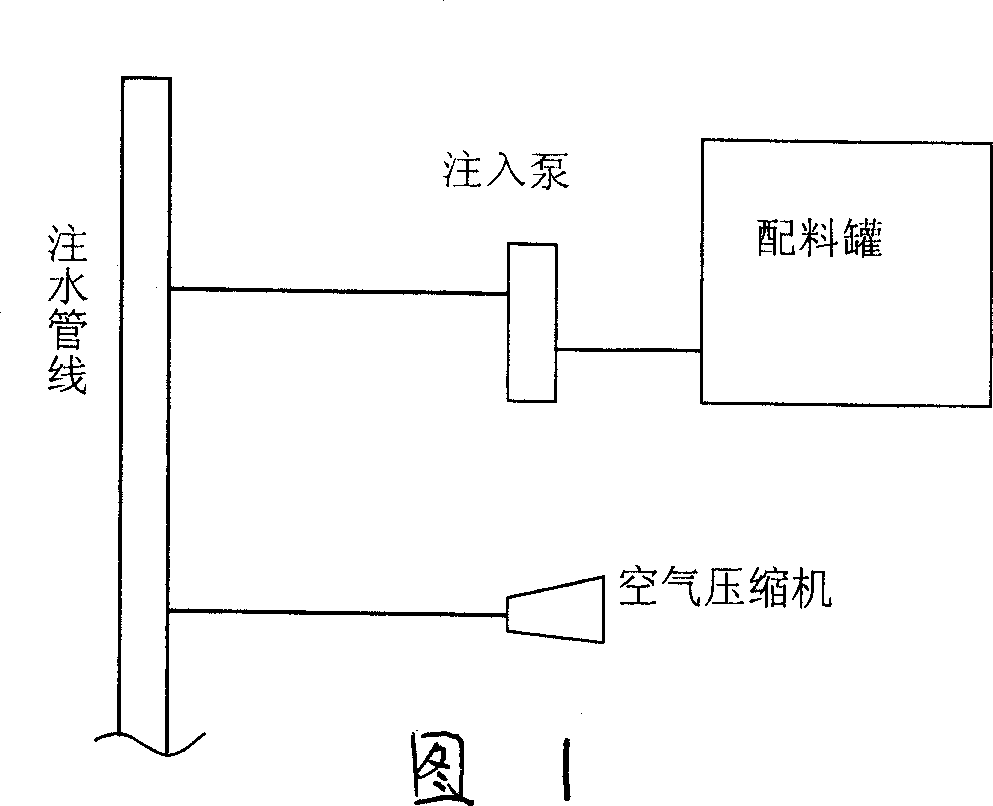

[0019] Embodiment 1, taking the daily water injection volume of 35000 kg as an example, 1157.28 kg of urea, NH 4 CL38.58 kg, amino acid 192.88 kg, NH 3 NO 3 38.58 kg, Na 2 HPO 4 115.73 kg, MgSO 4 ·7H 2 O 3.86 kg, FeSO 4 ·5H 2 O 19.29 kg, CaCl 2 19.29 kg, ZnCL 2 23.15 kg, molasses 1543.04 kg, rhamnose 38.58 kg and C 8~10 After 385.76 kg of alkyl glycosides were mixed in the batching tank, the injection pump injected the biological nutrient solution and compressed air into the formation by bypassing the water injection pipeline for pilot experiments. Each well was constructed for 5 rounds, and the construction continued for 2 years. The well was injected in 3 times, each time for 1 day, and the well was shut down for 1 day. Compared with the original method, the method increases the recovery factor by 10%, and the water content decreases by 2%.

Embodiment 2

[0020] Example 2, taking a daily water injection volume of 35,000 kg as an example, 760.79 kg of urea, 26.63 kg of NH4CL, 304.31 kg of amino acids, and 304.31 kg of NH 3 NO 3 57.06 kg, Na 2 HPO 4 190.20 kg, MgSO 4 ·7H 2 O 7.61 kg, FeSO 4 ·5H 2 O 30.43 kg, CaCl 2 38.04 kg, ZnCL 2 26.63 kg, molasses 760.79 kg, rhamnose 76.08 kg and C 8~10 After 760.79 kg of alkyl glycosides were mixed in the batching tank, the injection pump injected the biological nutrient solution and compressed air into the formation by bypassing the water injection pipeline for pilot experiments. Each well was constructed for 5 rounds, and the construction continued for 2 years. The well was injected in 3 times, each time for 1 day, and the well was shut down for 1 day. Compared with the original method, the method increases the recovery factor by 10%, and the water content decreases by 2%.

Embodiment 3

[0021] Embodiment 3, taking 35,000 kilograms of daily water injection as an example, 384.74 kilograms of urea, NH 4 CL19.24 kg, amino acid 384.74 kg, NH 3 NO 3 19.24 kg, Na 2 HPO 4 38.47 kg, MgSO 4 ·7H 2 O 19.24 kg, FeSO 4 ·5H 2 O 38.47 kg, CaCl 2 30.78 kg, ZnCL 2 38.47 kg, molasses 384.74 kg, rhamnose 192.37 kg and C 8~10 After 1923.71 kg of alkyl glycosides were mixed in the batching tank, the injection pump injected the biological nutrient solution and compressed air into the formation by bypassing the water injection pipeline for pilot experiments. Each well was constructed for 5 rounds, and the construction continued for 2 years. The well was injected in 3 times, each time for 1 day, and the well was shut down for 1 day. Compared with the original method, the method increases the recovery factor by 10%, and the water content decreases by 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com