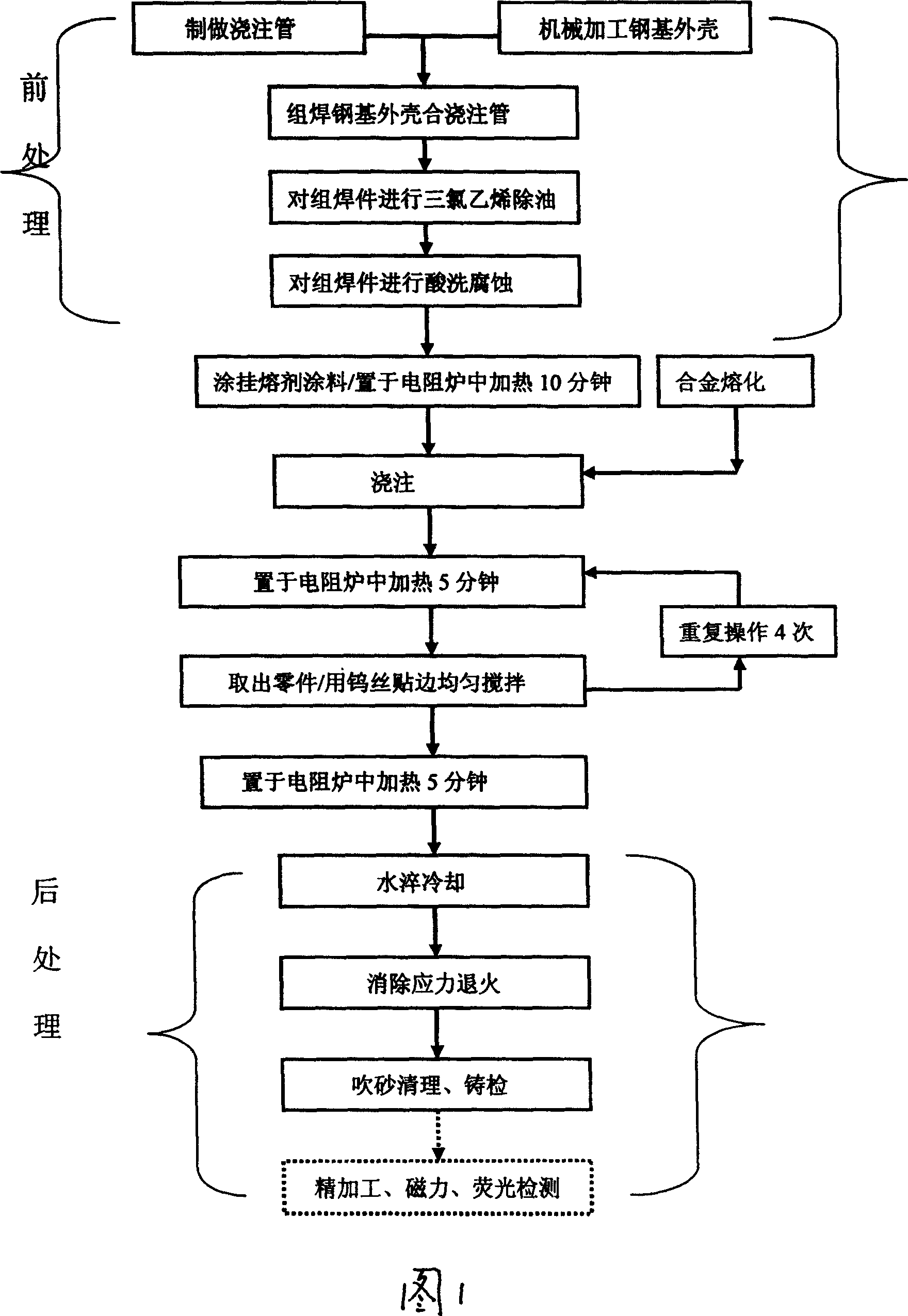

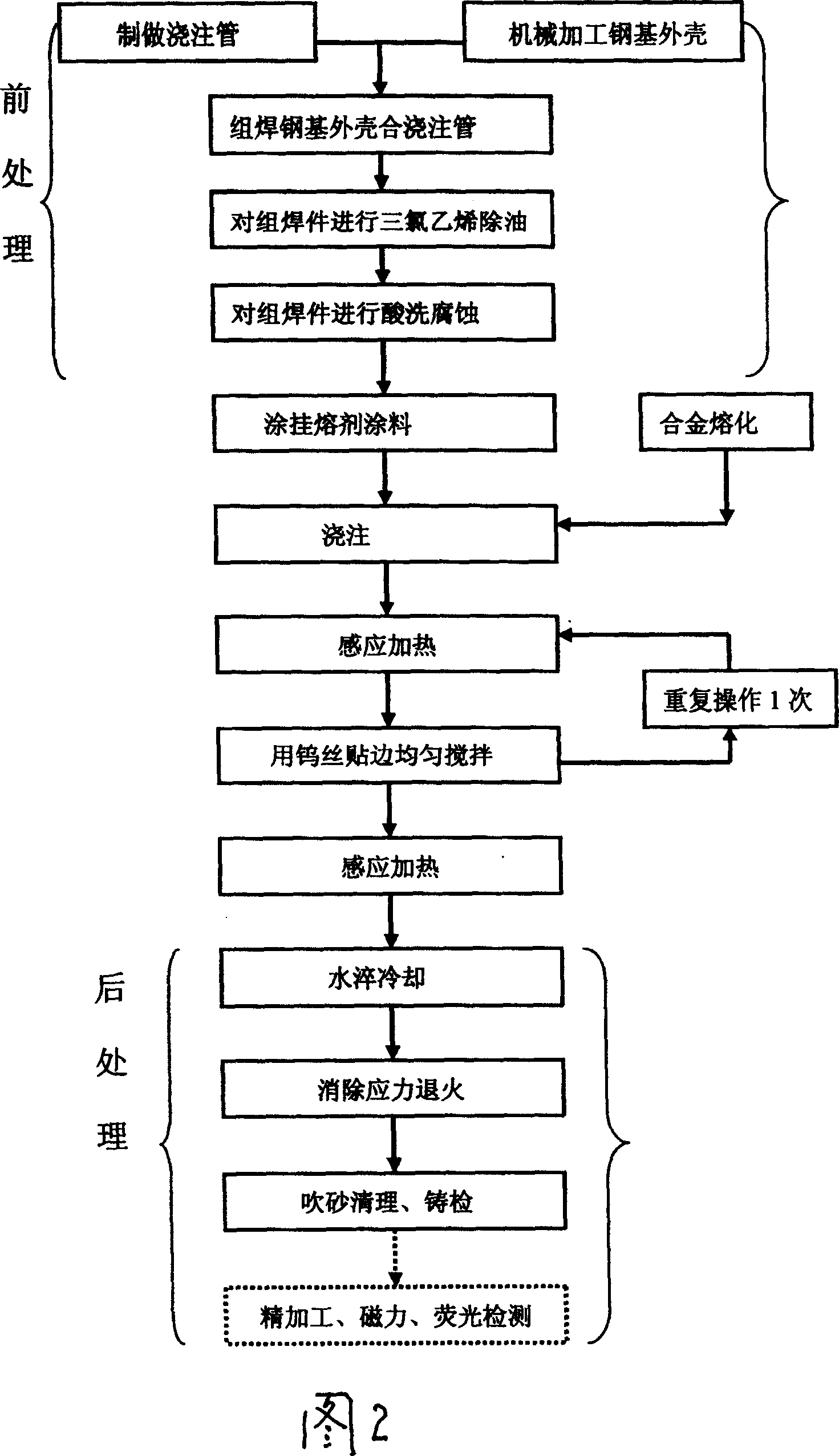

Improvement of working process to bimetal obturge part

A processing technology, bimetallic technology, applied in the field of processing technology of bimetallic sealed parts, can solve the problem of repeated entry and exit of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Silver Alloy Pouring Operation Data Card

Embodiment 2

[0026] Silver Alloy Pouring Operation Data Card

Embodiment 3

[0029] The working parameters of induction heating equipment are as follows:

[0030] Device model: PU100-43-80-08-02

[0031] Working frequency range: 7000KHz----9500KHz

[0032] Working voltage adjustment range: 0-400V

[0033] Working current adjustment range: 0---0.8KA

[0034] Working power range: 0---30KW

[0035] Silver Alloy Composition:

[0036] Ag: 41.0-43.0 Cu: 16.0-18.0 Zn: 15.0-17.0 Cd: 24.0-26.0

[0037] Tough flux: ES-5 brazing flux produced by Wuxi Chemical Research Institute

[0038] The core of the process is to use high-frequency induction to place the parts in the induction heating coil for heating, and to obtain the required heating temperature by adjusting a certain output voltage and maintaining it for a certain period of time. Therefore, the parts are stationary between each operation step, which effectively solves the disadvantages of large consumption of alloy, high labor intensity, low production efficiency, and low quality stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com