Method for cleaning and decontaminating polyesters

A technology of polyester and polyethylene terephthalate, applied in the direction of products, educts, reagents, etc., can solve the problems of increasing basic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

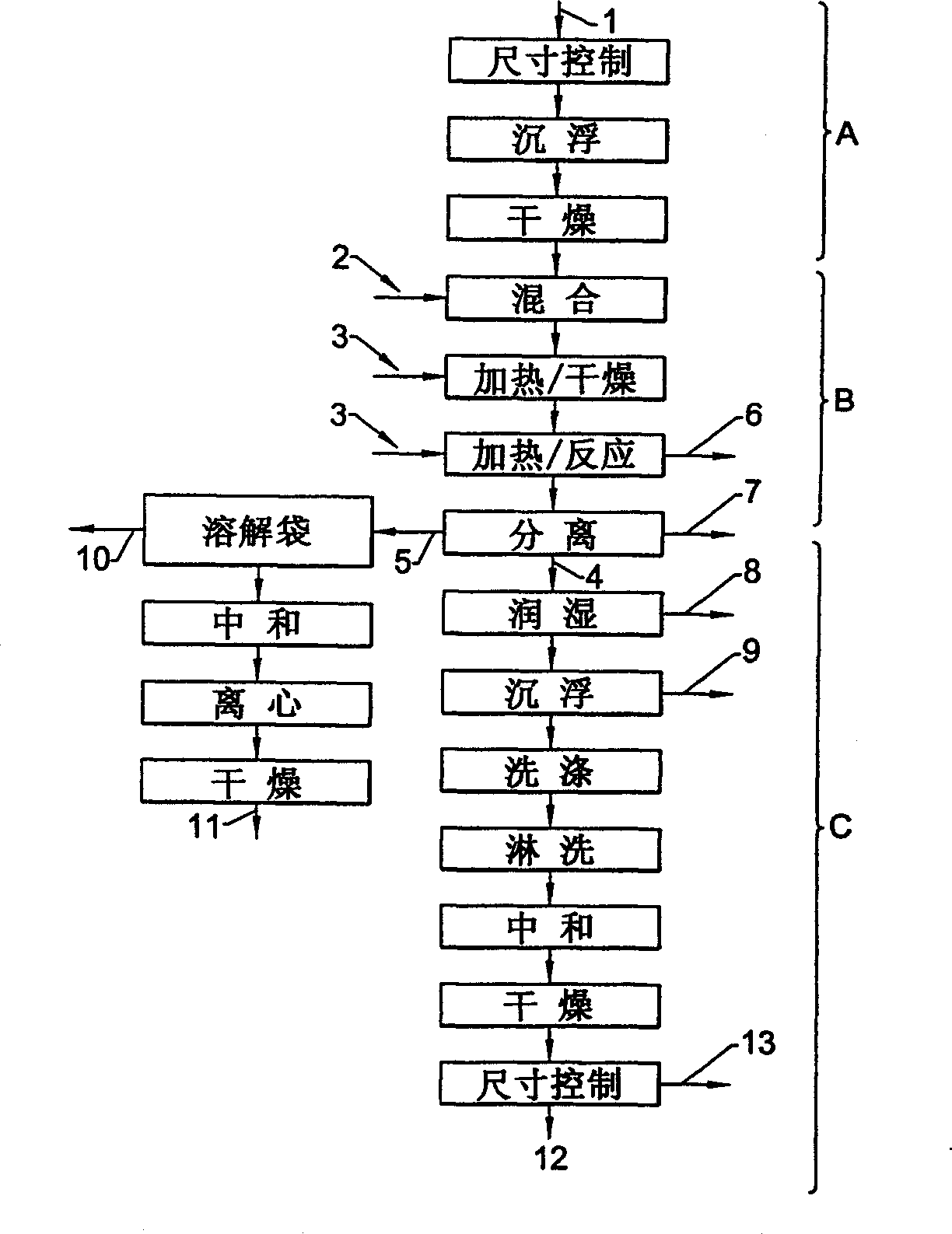

Method used

Image

Examples

Embodiment

[0071] 3,000 lbs of PVC-contaminated post-consumer PET bottles were ground into 3 / 8" nominal size flakes and added to a sinking tank to remove paper and polyolefin. The heavy fraction containing ground PET and PVC was mixed with 10% by weight of 50% sodium hydroxide solution was mixed and then fed into an electrically heated batch rotary kiln with a diameter of 54" and a heating length of 32'. The material was heated to 250°F while maintaining 600 cubic ft. / min of hot dry air purging the kiln (-80°F dew point, and 250°F temperature).

[0072] After 3 hours, the moisture content of the flakes was 0.2%, at which point the temperature of the flakes and air was raised to 400°F and held at that temperature for 9 hours.

[0073] The material is then cooled and added to a sink to remove degraded PVC. After sinking, the heavy fraction was washed with a REG MAC high shear washer for 2 minutes, followed by a rinse with a pH-4 phosphoric acid solution. After the acid rinse, the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com