Amorphous polystyrene base gas sensitive conductive composite material and preparation method thereof

A conductive composite material, polystyrene-based technology, applied in the field of amorphous polystyrene-based gas-sensitive conductive composite material and its preparation, to achieve high reusability, high sensitivity, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

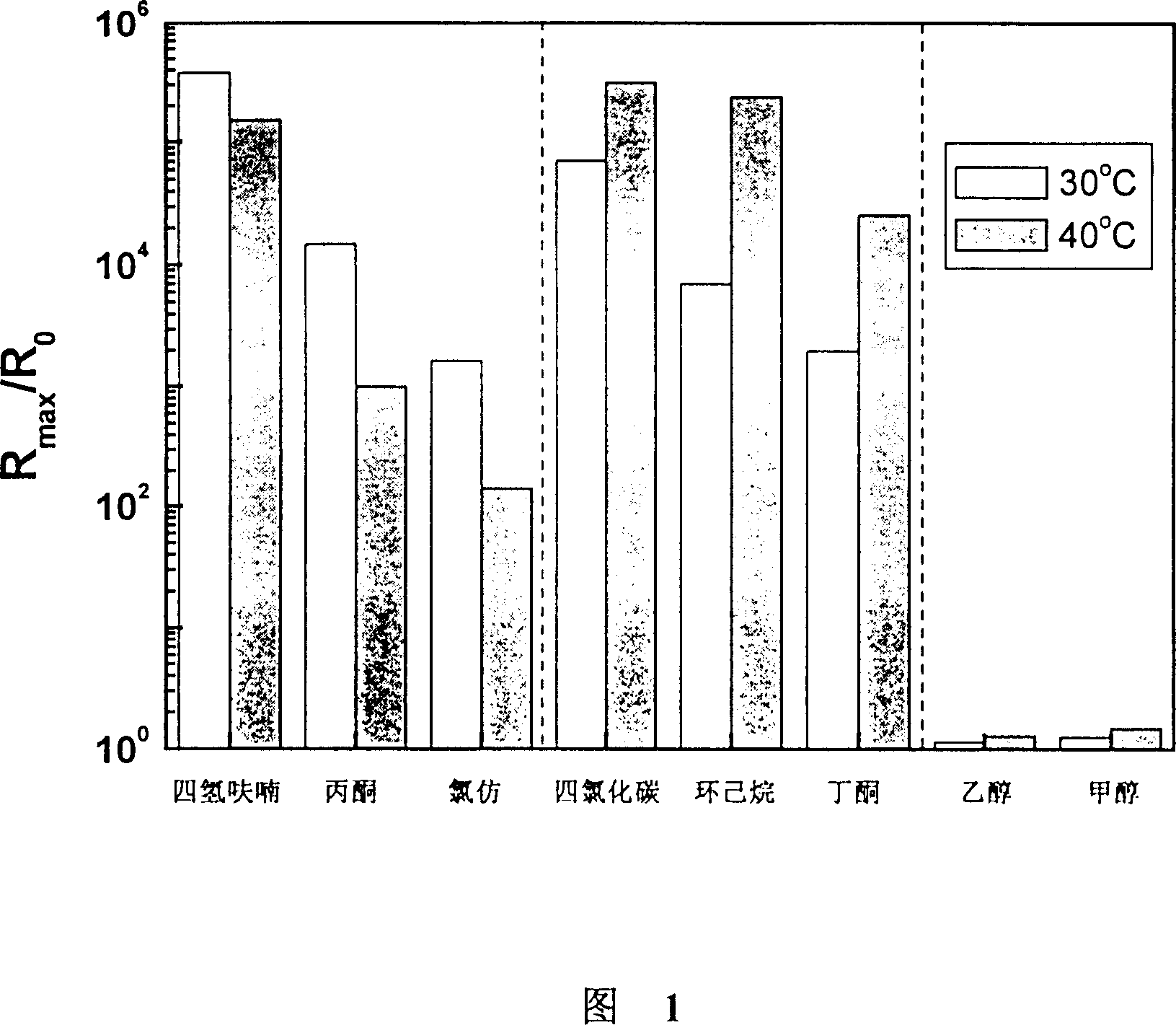

Image

Examples

Embodiment Construction

[0024] The group distribution of Examples 1-7 is shown in Table 1. The specific steps of the preparation method are as follows:

[0025] ① Add a certain amount of newly treated styrene monomer and 0.6wt% initiator to the reactor, and stir until the initiator is completely dissolved by nitrogen;

[0026] ②Add conductive fillers with a mass fraction of 8.5wt% to 21.4wt% according to the calculated amount, stir with nitrogen for 10 minutes, and then raise the temperature to 85°C for 4 hours and 150°C for 2 hours;

[0027] ③Cool down to 80℃, add an appropriate amount of good polystyrene solvent and continue to stir for 1h, then cool to room temperature;

[0028] ④ Coat the obtained sticky substance on the self-made glass electrode plate, dry it and vacuum-dry it at room temperature for 48 hours to obtain a composite electrode.

[0029] Comparative Examples 1-7 are prepared by blending industrial polystyrene and conductive filler using methyl ethyl ketone as a solvent solution.

[0030...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com