Waste water treating method and multi-effect evaporator for propylene oxide production

A technology for the production of waste water and propylene oxide, which is applied in multiple-effect evaporation, heating water/sewage treatment, distillation in boilers/distillates, etc., can solve the problem of increased production costs in processing steps, high chemical oxygen consumption, and aggravated sewage Body pressure and other issues, to achieve the effect of short heating time, fast evaporation speed, and reduced toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

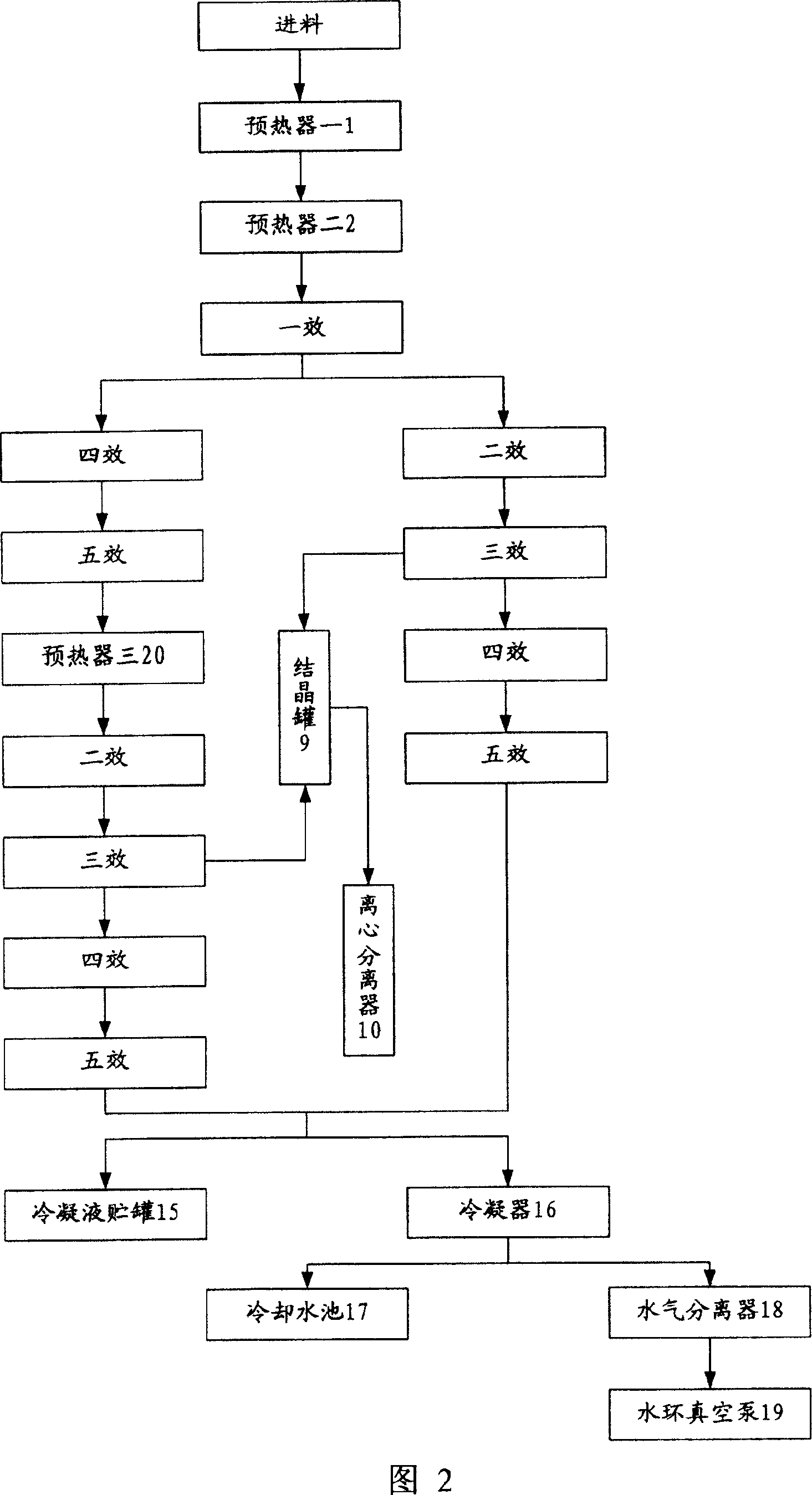

[0017] A kind of propylene oxide production wastewater treatment method of the present invention, the method comprises the following steps:

[0018] (1) First, the wastewater is subjected to multi-effect evaporation treatment to obtain a wastewater concentrate;

[0019] (2) Then, crystallize the wastewater concentrate to obtain calcium chloride crystals.

[0020] In the present invention, the multi-effect evaporator used in the above method is used for wastewater treatment, and the multi-effect evaporator is briefly introduced below.

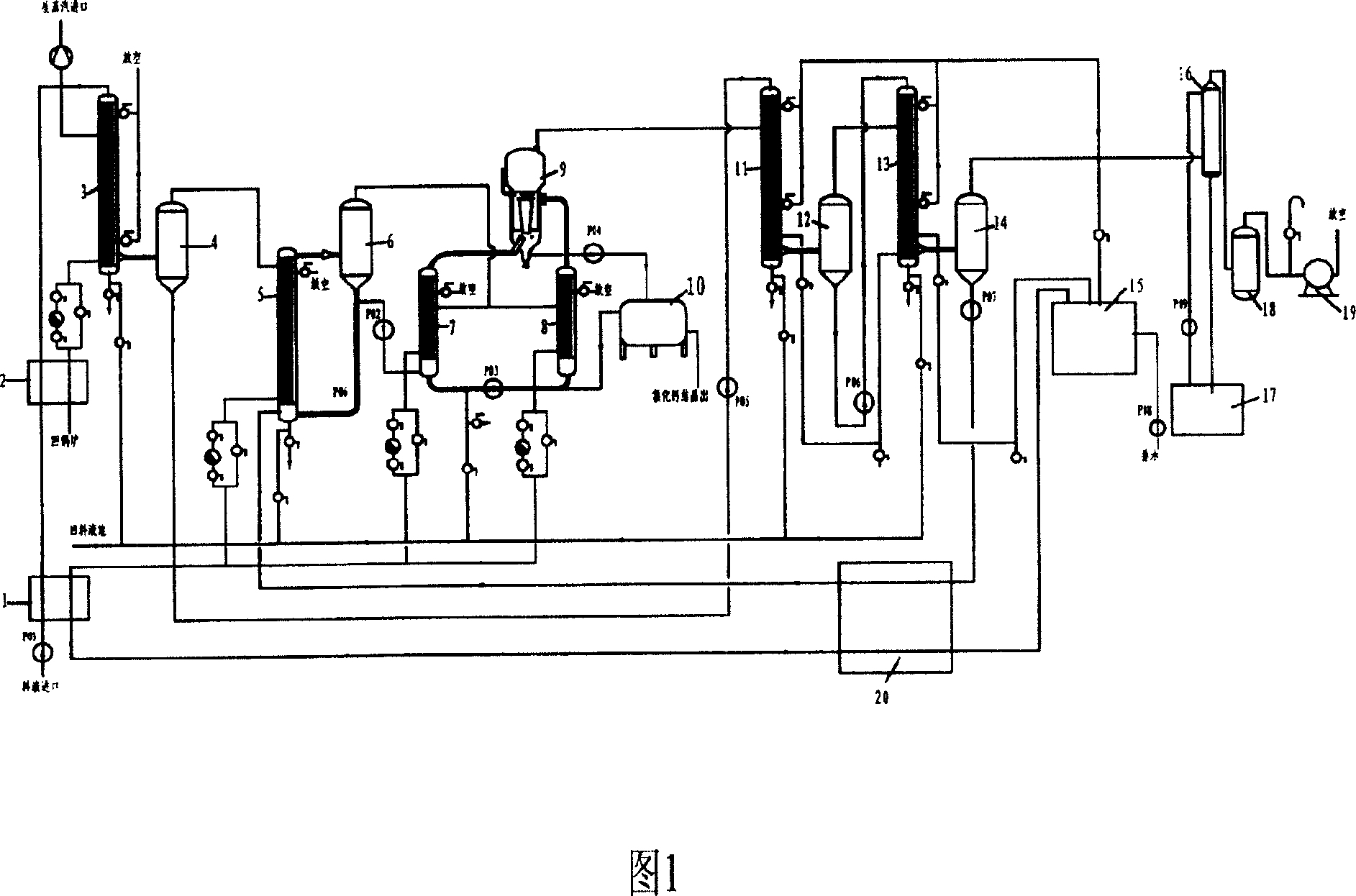

[0021] Referring to Fig. 1, in one embodiment of the present invention, the multi-effect evaporator can be a five-effect evaporator, and the five-effect evaporator mainly includes five effects, a crystallization tank 9 and a series of pipelines.

[0022] Among them, an effect refers to a zone of a multi-effect evaporator that is heated by steam (generally water vapor) and also releases steam into a subsequent zone, where it is used to supply pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com