Tilting plate type filtering pool

A filter tank and flap technology, which is used in filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of long backwashing time and cycle, large amount of backwashing water, and poor effluent quality. The effect of short backwashing time and cycle, small backwashing water consumption, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

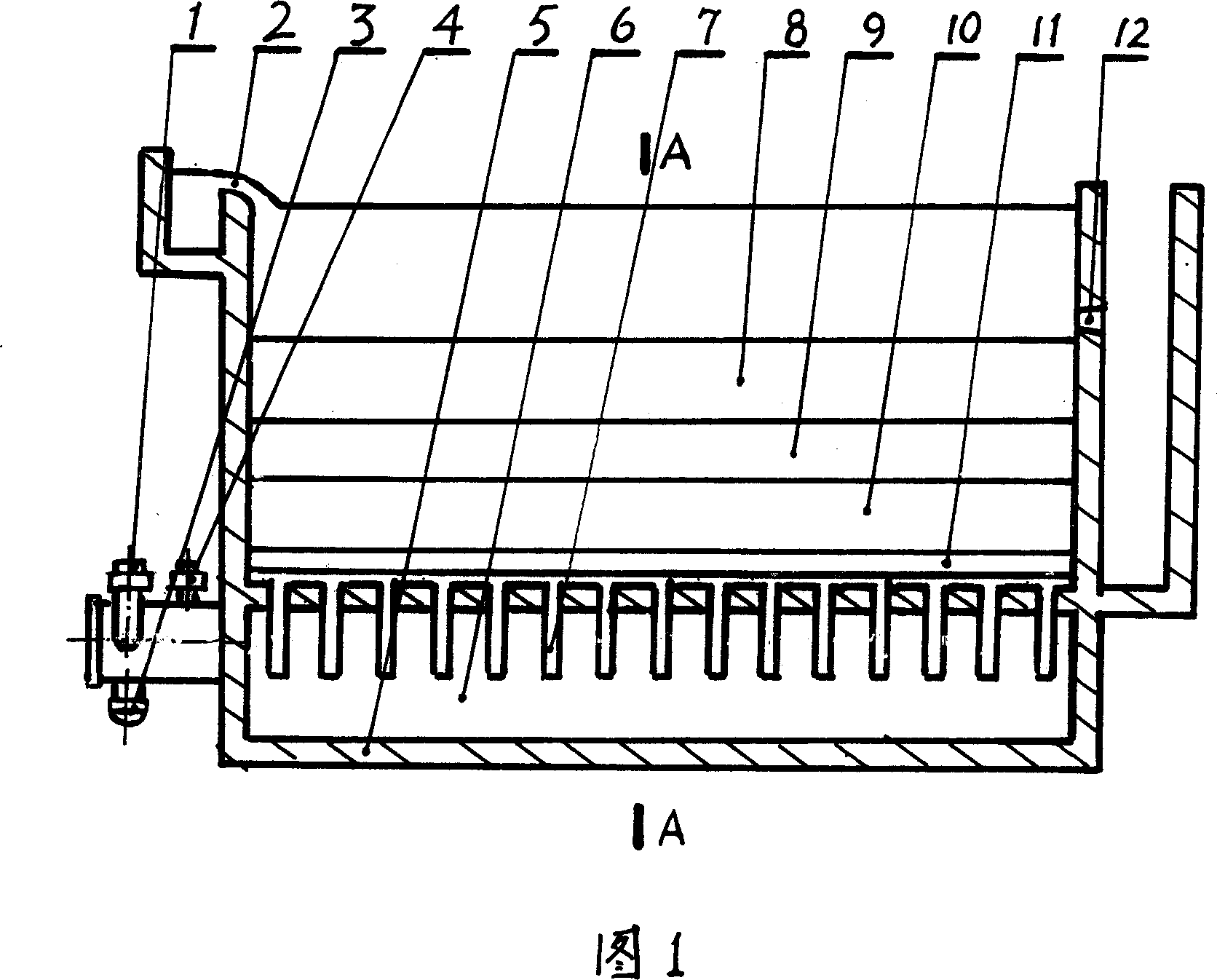

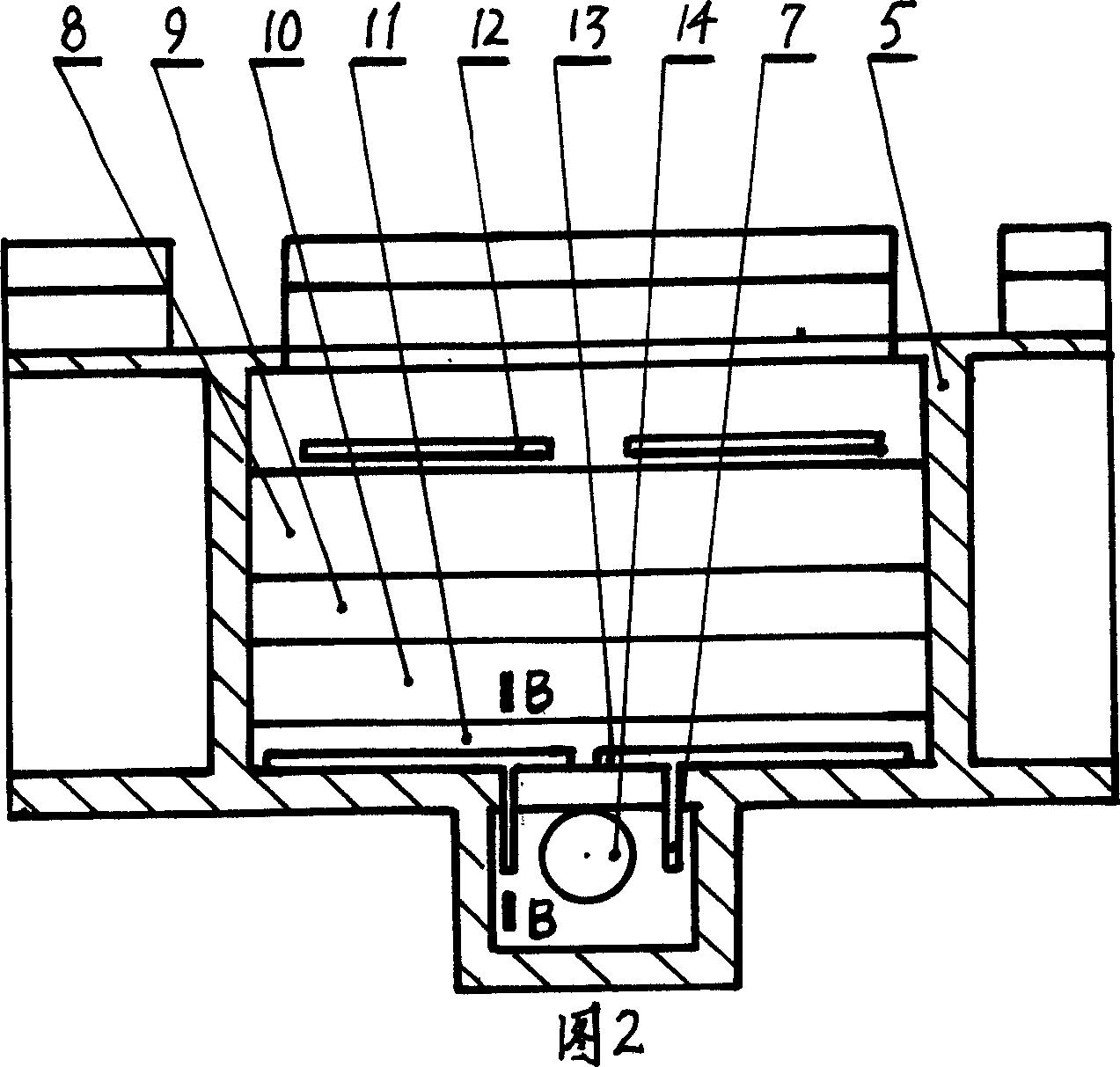

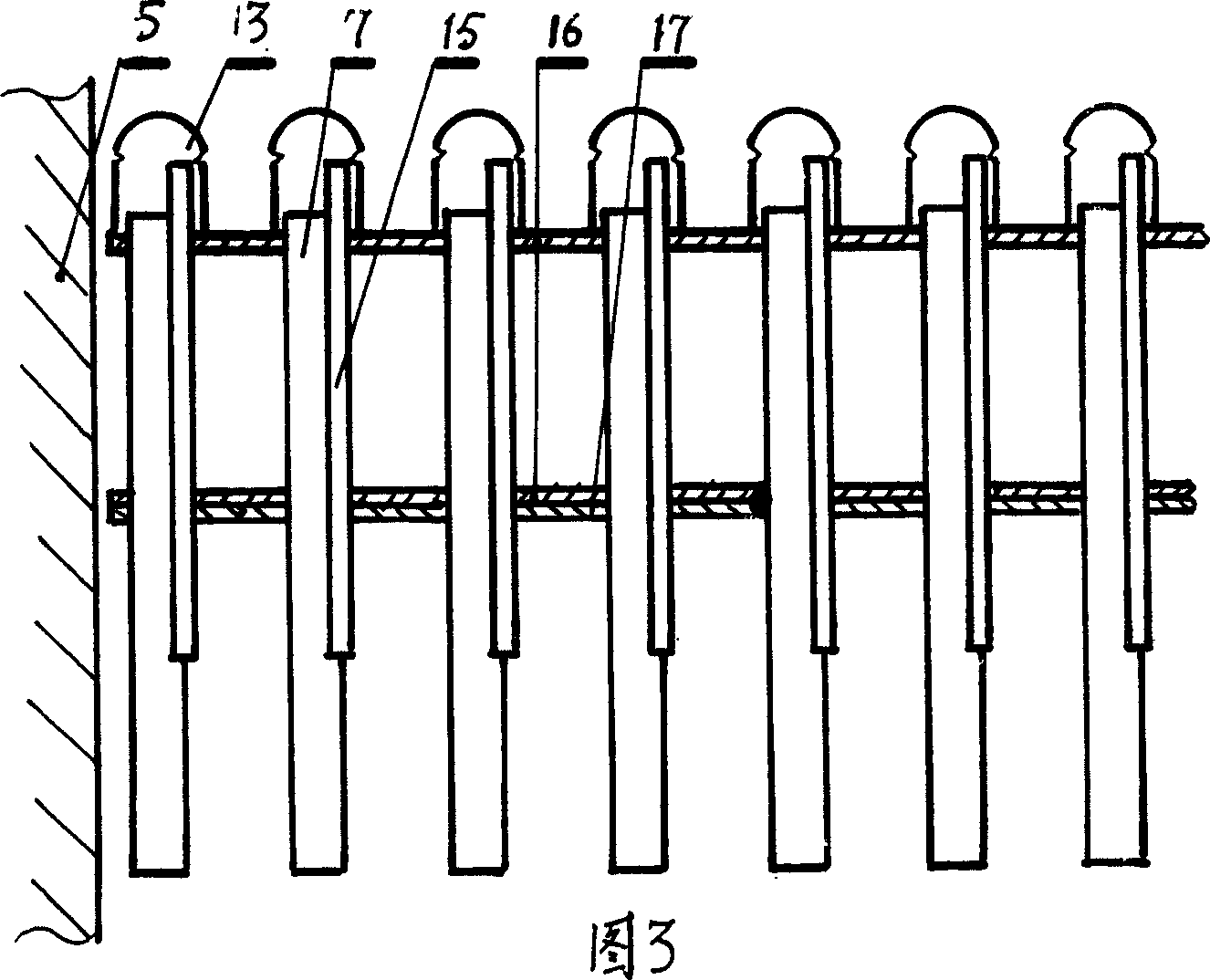

[0018] In Figures 1 to 10, the flap filter consists of the filter body 5, the backwashing system, the filtration system and the sewage system installed in the filter body 5 from bottom to top, and the backwashing system, the filtration system and the sewage system installed on the filter body 5. The water inlet and outlet system is composed. The backwash system includes a backwash valve 1 and a flush air valve 4. The filter system includes an anthracite coal layer 8, a quartz sand layer 9, a coarse sand layer 10, and a pebble layer 11 arranged from the top to the bottom, from the fine layer to the coarse layer. The water inlet and outlet system includes an overflow weir plate 2, a water outlet valve 3 and a water channel. The backwashing system also has the positioning steel plate 16 fixed in the filter body 5 and the water distribution straight pipe 7 and the air distribution straight pipe 15 on the pallet 17, and the water distribution cloth fixed on the top of the water distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com